In the dynamic realm of print technology, the **DTF Gangsheet Builder** stands out as an essential tool for enhancing efficiency in Direct to Film (DTF) printing. This innovative approach not only facilitates the seamless integration of multiple designs onto a single sheet but also significantly reduces material waste and lowers costs. By mastering gangsheet printing techniques, businesses can streamline their workflow and optimize their print layout, resulting in increased productivity and profit margins. Whether you are a small enterprise or a large-scale operation, mastering DTF printing efficiency can lead to remarkable improvements in your output. Join us as we explore strategic methods to maximize DTF printing effectiveness and elevate your business operations.

The process of DTF printing, or Direct to Film printing, revolutionizes how designs are transferred onto various fabrics, making it a vital technique for modern print businesses. Utilizing a gangsheet builder allows for the effective arrangement of multiple prints, thereby enhancing overall productivity while minimizing waste. This article will introduce various DTF printing strategies aimed at improving efficiency and ensuring optimal results. From design layout optimization to material selection, we will dive into the important aspects that can help you achieve maximized printing success. So, if you’re looking to elevate your print operations, read on to discover the advantages of employing DTF gangsheet techniques.

Understanding the Importance of DTF Printing Efficiency

Maximizing efficiency in DTF printing is crucial for achieving optimal output and reducing overall costs. DTF (Direct to Film) printing efficiency encompasses several key factors, including ink usage, time management, and energy consumption. By being mindful of these elements, businesses can create a streamlined process that not only enhances productivity but also contributes to sustainability. Implementing practices such as print layout optimization can significantly cut down on waste and improve operational performance.

Owning the ability to maintain high DTF printing efficiency can set a business apart in a competitive market. This involves understanding the intricate relationship between design creation and the production schedule. For example, ensuring that designs are set up to print multiple copies on a gangsheet can reduce the frequency of printer setup, thereby minimizing downtime and maximizing machine utilization. Engaging in effective gangsheet printing techniques allows businesses to achieve faster turnaround times and increased overall satisfaction.

The Role of DTF Gangsheet Builder in Optimization

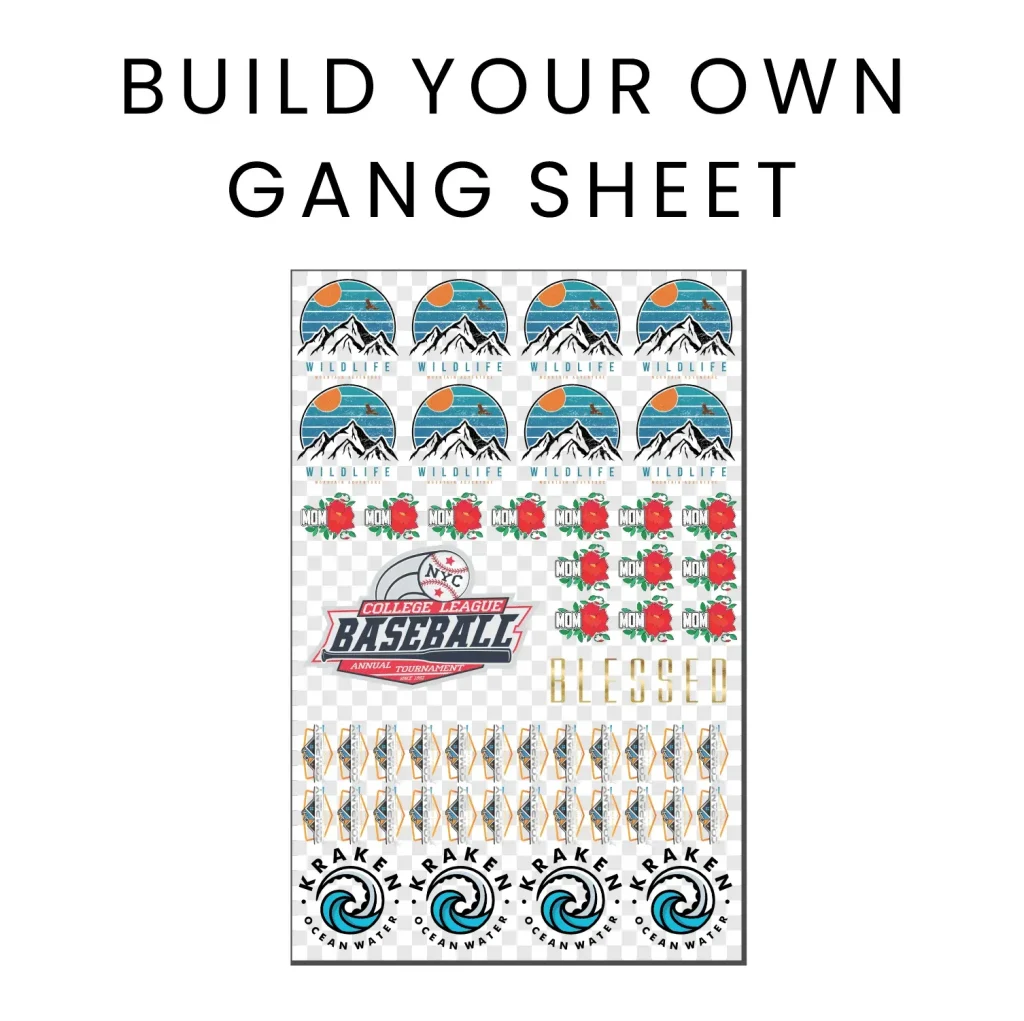

The DTF Gangsheet Builder is an essential tool that revolutionizes how printing operations manage layouts. This builder allows users to create templates that maximize the potential of each sheet, ensuring that every inch of transfer film is utilized efficiently. By utilizing DTF gangsheet builder capabilities, operators can drastically reduce material waste and align their production processes with best practices for DTF printing strategies.

Effective use of the DTF Gangsheet Builder not only enhances layout organization but also facilitates better design distribution across the transfer film. It allows for the amalgamation of various designs, making it easier to manage print jobs and meet diverse customer demands. By implementing this tool, organizations can leverage gangsheet printing techniques to improve their workflow, thus ensuring a high level of productivity and satisfaction among clients.

Techniques for Effective Print Layout Optimization

Print layout optimization is instrumental in achieving high efficiency during the DTF printing process. A well-optimized layout not only conserves materials but also promotes faster printing cycles by minimizing the need for repetitive adjustments or setup configurations. Utilizing design software designed for this purpose can facilitate advanced adjustments, enabling printers to fill in gaps and maximize space effectively. Such proactive planning allows for more prints to be completed in fewer runs.

Moreover, an effective layout stresses the importance of strategic spacing and alignment of designs on the gangsheet. By paying close attention to these elements, printers can ensure clean transfers without overlap or misalignment, ultimately resulting in higher-quality finished products. Employing techniques such as tiered placement of designs can yield better space usage and allow for varying fabric types to be accommodated, further supporting the fulfillment of diverse customer requests.

Batch Printing: A Strategy for Streamlining Production

Batch printing represents a significant advancement in DTF printing efficiency, facilitating a streamlined approach to production. By consolidating similar print jobs into a single batch, printers can drastically reduce setup time for each job, resulting in an impressive turnaround efficiency. This strategy not only serves to minimize interruptions in workflow but also allows for better utilization of machine resources throughout the day.

Furthermore, batching enables operators to optimize print settings without the hassle of switching configurations frequently. By ensuring that the printer’s settings are locked in for similar designs, you reduce the likelihood of errors, which can cause delays and additional waste. As a result, businesses can expect larger batch runs to translate into higher productivity and overall operational efficiency.

Selecting Quality Materials for DTF Success

The selection of materials in DTF printing directly affects the overall efficiency and quality of the output. High-quality transfer films and inks not only ensure superior results but also play a pivotal role in reducing the need for corrections and reprints. Premium materials are less prone to tearing or misalignment issues, minimizing downtime during productions. Investing in reliable fabric and ink options aligns with DTF printing strategies focused on long-term success.

Additionally, the right materials can lead to better color retention and durability after washing, which in turn enhances customer satisfaction. Ultimately, ensuring that the basic elements of the DTF process are of the highest quality optimizes the overall production cycle. This aspect reinforces the importance of evaluating supplier options and remaining vigilant about material choices to truly maximize DTF printing efficiency.

Training Staff for Enhanced Printing Operations

Investing in team training is paramount for increasing DTF printing efficiency. When staff members are well-versed in the intricacies of DTF printing and the functions of the gangsheet builder, they can operate machinery with increased confidence and proficiency. Comprehensive training programs empower employees to make informed decisions and encourage innovation, which can lead to optimized workflows and improved overall printing quality.

Moreover, establishing clear standard operating procedures (SOPs) within the printing operation minimizes the likelihood of errors and inefficiencies. Regular training sessions should be supplemented with documentation that reflects the latest techniques and updates. This ensures that everyone involved remains aware of advancements in DTF printing strategies, ultimately leading to more cohesive and productive working environments.

Frequently Asked Questions

What advantages does the DTF Gangsheet Builder offer for maximizing DTF printing efficiency?

The DTF Gangsheet Builder enhances DTF printing efficiency by optimizing design layouts on transfer films, reducing waste, and enabling batch printing. This means you can print multiple designs simultaneously, saving time and lowering costs by maximizing the use of ink and materials.

How can print layout optimization with a DTF Gangsheet Builder reduce costs?

Print layout optimization using a DTF Gangsheet Builder minimizes excess ink and film waste. By efficiently arranging designs on a single sheet, you can increase the number of prints per batch, leading to reduced material costs and improved overall profitability.

What are effective DTF printing strategies when using a Gangsheet Builder?

Effective DTF printing strategies with a Gangsheet Builder include optimizing design placement for maximum usage of space, selecting high-quality materials, and regular maintenance of equipment. These strategies help ensure high-quality prints and lower production costs.

Can the DTF Gangsheet Builder improve my productivity in printing operations?

Yes, the DTF Gangsheet Builder significantly boosts productivity by allowing batch printing of multiple designs, streamlining the workflow, and reducing setup time between prints. This leads to a more efficient operation and faster turnaround times for projects.

What role does material selection play in DTF printing efficiency with a Gangsheet Builder?

Material selection is crucial in DTF printing efficiency. High-quality films and inks help ensure better adherence and reduce the likelihood of errors, which can waste resources. Using the right materials with your DTF Gangsheet Builder helps maintain quality while enhancing productivity.

How can training improve the effectiveness of the DTF Gangsheet Builder in printing?

Investing in training enhances the effective use of the DTF Gangsheet Builder by ensuring staff understand DTF printing techniques and best practices. Well-trained teams can better utilize the gangsheet layout to maximize efficiency, ensuring consistent quality and reducing the margin for error.

| Key Point | Description |

|---|---|

| What is DTF Printing? | Direct to Film (DTF) printing allows vibrant designs to be printed onto transfer film for application on fabrics, featuring quick setup and multi-color capabilities. |

| Understanding Gangsheet Builders | Gangsheet is a method where multiple designs are printed on a single transfer film sheet, enhancing resource efficiency and minimizing waste. |

| Optimize Design Layout | Use specialized software to arrange designs densely, maximizing space and minimizing ink waste. |

| Batch Printing | Grouping similar designs streamlines the printer setup process, reduces downtime, and enhances workflow efficiency. |

| Material Selection | Choosing high-quality films and inks reduces the need for test prints, saves resources, and improves print quality. |

| Calibration and Maintenance | Regular printer calibration and maintenance reduce errors, save resources, and prolong equipment lifespan. |

| Understand the Transfer Process | Master appropriate temperature and pressure settings for different fabrics to ensure successful transfers and minimize waste. |

| Training and SOPs | Investing in team training and establishing standard operating procedures ensure consistent quality and operational efficiency. |

| Create a Feedback Loop | Encourage employee feedback to foster a culture of continuous improvement and adaptability within operations. |

Summary

The DTF Gangsheet Builder is an essential tool for optimizing the efficiency of your DTF printing operation. By integrating effective design practices, quality materials, and a well-trained workforce into your workflow, you can achieve a seamless production process that significantly boosts productivity. Understanding the nuances of DTF printing, from layout optimization to equipment maintenance, allows for reduced waste and enhanced print quality. As the DTF printing landscape evolves, embracing these strategies will help you maintain a competitive edge, ensuring your business thrives in this dynamic industry.