The DTF Gangsheet Builder is revolutionizing the world of Direct-to-Film printing by offering print shops an innovative way to maximize efficiency without sacrificing quality. As the demand for high-quality prints continues to rise, businesses are turning to cost-effective printing solutions that meet both customer expectations and operational needs. This powerful tool allows users to streamline their workflows while producing vibrant designs on various substrates, making it an essential addition to any modern print shop. By leveraging DTF printing technology, shops can significantly reduce waste and improve print shop efficiency, ultimately leading to increased profits. In this article, we will explore the numerous advantages the DTF Gangsheet Builder brings to the table and why every print shop should consider implementing it to stay competitive in the industry.

The DTF Gangsheet Builder, also known as the Direct-to-Film sheet organizer, plays a crucial role in modern printing practices, particularly in the realm of DTF printing processes. This innovative software solution is designed to enhance the operational efficiency of print businesses while maintaining the high-quality standards expected by clients. By automating the layout and arrangement of multiple designs on a single film sheet, it enables print shops to offer more cost-effective printing solutions. The versatility and effectiveness of this technology help businesses adapt to a diverse range of customer needs, making it a vital resource in today’s competitive print market. As we delve deeper into this topic, it becomes clear that the benefits of using a Gangsheet Builder extend far beyond mere convenience.

The Benefits of Direct-to-Film Printing

Direct-to-Film (DTF) printing technology is revolutionizing the print industry by providing a flexible, cost-effective solution for producing high-quality prints. One of the main advantages of DTF printing is its ability to cater to various fabrics, making it an appealing choice for diverse customer needs. Whether you are printing on cotton, polyester, or blends, DTF can handle it all with exceptional detail and vibrant colors. This versatility allows print shops to expand their service offerings, attracting a broader clientele and ultimately increasing revenue.

Moreover, DTF printing eliminates many of the complications associated with traditional methods, such as extensive setup costs and lengthy production times. The simplified process allows for quicker turnaround periods, enabling print shops to meet tight deadlines without sacrificing quality. This efficiency not only enhances customer satisfaction but also builds a positive reputation in the market, positioning your business as a reliable provider for high-quality prints.

Enhancing Print Shop Efficiency with DTF Technology

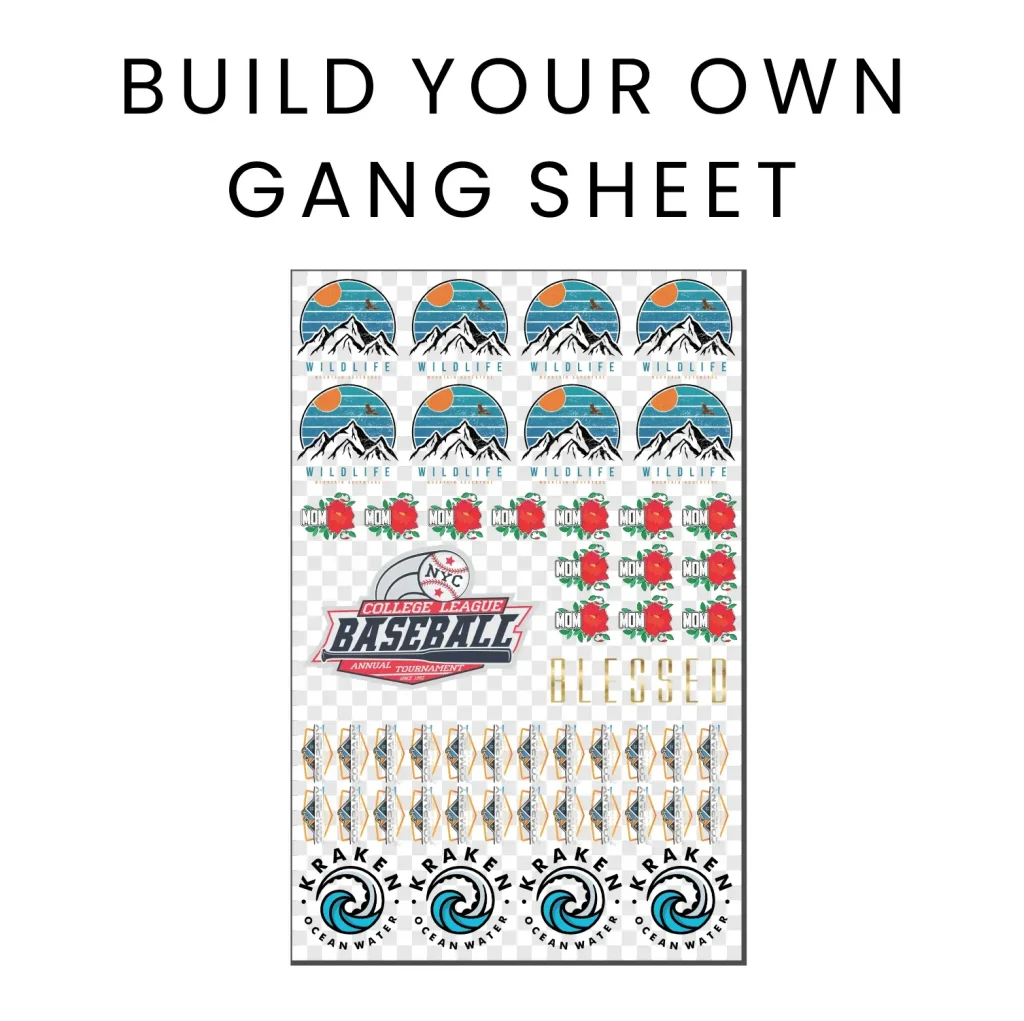

Efficiency is crucial in the printing industry, and DTF Gangsheet Builder plays a vital role in enhancing operational workflows. By enabling print shops to maximize the use of each film sheet, this tool minimizes waste and cuts down on material costs. The ability to print multiple designs in one go not only optimizes resource usage but also saves valuable time during the production process. This capacity to work smarter, not harder, sets print shops apart, ensuring they remain competitive in a crowded marketplace.

Furthermore, DTF technology allows for streamlined operations, significantly reducing the chances of human error. With automated processes and real-time previews, print operators can adjust designs effortlessly, ensuring consistent high-quality outputs on every order. The integration of the DTF Gangsheet Builder into daily operations can lead to a more organized workflow, which translates into improved productivity and lower operational costs.

Cost-Effectiveness of the DTF Gangsheet Builder

In an era where budget constraints are paramount for print businesses, the DTF Gangsheet Builder stands out as a cost-effective solution. By reducing material waste and labor costs associated with traditional printing methods, print shops can achieve substantial financial savings. The Gangsheet Builder enables operators to create multiple designs within one print run, decreasing the overall expenditure while maintaining competitive pricing.

Additionally, the efficient use of materials ensures that print shops can provide their services at lower rates without compromising quality. This approach not only attracts price-sensitive customers but also enhances profit margins. Print shops that leverage the capabilities of the DTF Gangsheet Builder are better positioned to thrive financially, providing high-quality prints at accessible prices.

Achieving High-Quality Results with DTF Gangsheet Technology

Quality is non-negotiable in the printing business, and the DTF Gangsheet Builder excels in delivering high-quality outputs consistently. The technology’s ability to print intricate designs with vibrant colors ensures that every print meets customer expectations. By maintaining the same standards across all designs, print shops can significantly improve client satisfaction and foster loyalty.

Moreover, DTF printing’s durability adds to the perceived quality of the final product. With prints that resist fading and wear, customers enjoy a longer-lasting result, enhancing their overall experience with the print shop. The combination of DTF technology and the Gangsheet Builder guarantees that print shops not only meet but exceed their clients’ expectations, positioning them as leaders in quality service.

Automation in Print Manufacturing: The Role of DTF Gangsheet Builder

As automation becomes increasingly important in print manufacturing, the DTF Gangsheet Builder leads the way in enhancing operational efficiencies. This software automates the positioning of designs on film sheets, alleviating labor-intensive tasks that can lead to human error. Print shops can benefit from this automation, as it allows employees to focus on other critical aspects of the business, increasing overall productivity.

Furthermore, the real-time capabilities of the DTF Gangsheet Builder enable immediate adjustments to be made, ensuring designs are accurately represented before printing begins. This automation not only speeds up workflows but also guarantees that print shops can adapt quickly to changes in client requests, reflecting a modern approach to print production that leverages technology to its fullest.

Catering to Diverse Client Demands with DTF Technology

In today’s market, customer demands are ever-diversifying, requiring print shops to be adaptable and responsive. The DTF Gangsheet Builder allows businesses to cater to diverse requests efficiently, from personalized one-off items to large batch orders. By facilitating the rapid adjustment of designs, print shops can better serve their clients’ unique needs, fostering a reputation for flexibility and innovation.

This capability to cater to diverse client needs enhances customer satisfaction and boosts repeat business. As consumer preferences continue to evolve towards personalized products, print shops equipped with DTF technology can seize these opportunities, ensuring they remain relevant and in-demand. This adaptability is essential for thriving in a competitive landscape where customer expectations are continuously rising.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance print shop efficiency?

The DTF Gangsheet Builder is a specialized tool designed to optimize the Direct-to-Film (DTF) printing process. It allows print shops to arrange multiple designs on a single sheet of film, minimizing waste and maximizing material use. This increased efficiency leads to faster production times and reduced labor costs, making it an essential tool for print shops aiming to improve their operational efficiency.

How does the DTF Gangsheet Builder improve the quality of high-quality prints?

The DTF Gangsheet Builder ensures design consistency across multiple prints by maintaining proper alignment and spacing. This results in high-quality output that meets clients’ expectations. By automating the layout process, print shops can achieve intricate and vibrant designs without sacrificing quality, which is crucial for customer satisfaction.

What are the cost benefits of using the DTF Gangsheet Builder in print shops?

Using the DTF Gangsheet Builder can significantly reduce costs associated with material and labor. By maximizing the use of every sheet, print shops can cut down on ink, transfer, and film costs. This cost-effective approach allows businesses to offer competitive pricing while enhancing profit margins, making the DTF Gangsheet Builder a valuable investment for any print operation.

What types of substrates can the DTF printing technology, complemented by the Gangsheet Builder, print on?

DTF printing technology is highly versatile, allowing print shops to print on a wide range of substrates including cotton, polyester, and various blends. The DTF Gangsheet Builder enhances this versatility by enabling customization for different client requests, accommodating both small runs and larger orders effectively.

How can print shops integrate the DTF Gangsheet Builder into their existing workflows?

To integrate the DTF Gangsheet Builder, print shops should begin by researching suitable software options that fit their needs. Training staff on the new system is essential to ensure smooth adoption. Starting small with specific projects can help identify improvements in workflow before full implementation, enhancing overall efficiency in print shop operations.

Why is Direct-to-Film printing technology gaining popularity among print shops?

Direct-to-Film (DTF) printing technology is gaining popularity due to its cost-effectiveness, flexibility, and capacity for high-quality prints. It simplifies the production process, reduces setup costs, and allows for vibrant designs on various substrates. The addition of tools like the DTF Gangsheet Builder maximizes these benefits, making DTF printing an attractive option for print shops.

| Key Point | Details |

|---|---|

| Cost Efficiency | DTF printing reduces setup costs significantly, especially for small to medium runs, allowing competitive pricing. |

| Flexibility and Versatility | DTF printing works on various fabrics like cotton and polyester, expanding the customer base. |

| High-Quality Output | Produces vibrant colors and intricate designs with durability against environmental factors. |

| Simplified Production Process | Eases printing processes leading to faster production times and fewer errors. |

| Environmental Considerations | Uses water-based inks, positioning DTF as a more eco-friendly printing option. |

| Maximizing Efficiency | Enables creation of multiple designs on a single sheet, minimizing waste and saving materials. |

| Streamlined Workflows | Automates much of the design process with drag-and-drop features and real-time previews. |

| Improved Print Quality | Ensures consistent spacing and alignment across prints for high-quality results. |

| Cost Savings | Reduces waste, leading to lower overall costs for material and labor, enhancing competitive pricing. |

| Catering to Diverse Clientele | Allows quick adjustments to designs for various client requests without delays. |

Summary

The DTF Gangsheet Builder is essential for print shops looking to enhance their efficiency and quality outputs. This innovative tool allows businesses to maximize their production capabilities by enabling multiple designs on a single film, thereby reducing waste and increasing margins. With the growing demand for Direct-to-Film (DTF) printing, integrating the DTF Gangsheet Builder not only simplifies workflows but also assures consistent, high-quality results that meet diverse customer needs. By investing in this technology, print shops will position themselves for long-term success in a competitive industry, ensuring they can adapt quickly to evolving market demands.