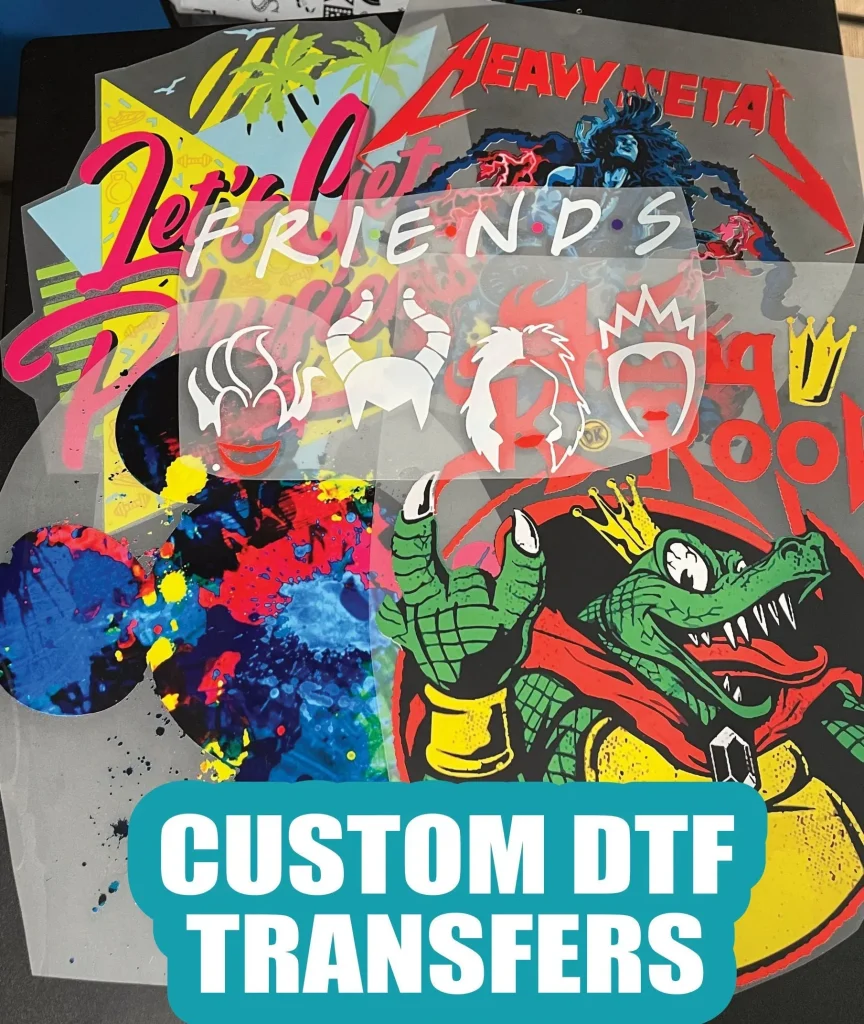

DTF transfers, short for Direct-to-Film transfers, are revolutionizing the custom printing landscape by allowing for high-quality designs on a variety of fabrics. This innovative printing technology offers businesses an efficient and versatile solution for creating stunning, personalized products, particularly in apparel printing. As more consumers seek unique and custom-made items, the demand for eco-friendly printing options like DTF is on the rise. Not only do DTF transfers produce vibrant, long-lasting prints, but they also align with modern sustainability practices, making them an ideal choice for environmentally conscious brands. In this article, we will delve into the specifics of DTF transfers and explore how they are shaping the future of custom printing.

Often referred to as Direct-to-Film printing, DTF transfers represent an exciting leap in the realm of printing technology. This advanced method utilizes a specialized film to create designs that can be effortlessly transferred onto various materials, making it a popular choice for custom apparel and promotional items. As the printing industry embraces innovative processes, the shift towards more sustainable practices is evident, particularly in the use of water-based inks that minimize environmental impact. DTF technology not only streamlines production but also meets the diverse needs of consumers looking for high-quality, customized products. In navigating the future of custom printing, DTF transfers stand out for their flexibility, quality, and commitment to eco-friendly solutions.

Understanding DTF Transfers

Direct-to-Film (DTF) transfers represent a pioneering stride in the custom printing sector, merging innovative technology with traditional artistry. At its core, DTF printing involves printing designs onto a special film, which is then heat-pressed onto the desired fabric. This process allows for vivid, high-resolution images that can seamlessly adhere to a wide range of materials, including cotton and polyester blends. This method not only enhances the aesthetic appeal of the printed fabric but also significantly elevates the overall consumer experience.

Understanding the DTF process is essential for businesses aiming to tap into the custom apparel market. The transition from traditional ink methods to DTF technology reflects the industry’s shift towards more modern, efficient, and versatile solutions. By investing in DTF transfers, companies can cater to diverse customer needs, offering eye-catching prints without the exorbitant costs associated with traditional printing methods. Thus, grasping the basics of DTF printing becomes crucial for anyone looking to succeed in this competitive landscape.

The Advantages of DTF Technology

DTF technology is rapidly gaining recognition for its multitude of advantages over conventional printing methods. One of the most compelling benefits is the quality of the final product. DTF transfers produce cleaner finishes with vibrant color reproduction, enabling intricate designs and text to stand out. This quality not only appeals to customers but also upholds the brand’s reputation for excellence, making it a smart choice for businesses aiming to differentiate themselves in the crowded apparel market.

Furthermore, DTF’s efficiency in production time sets it apart from traditional practices like screen printing. By eliminating the need for multiple setups for different colors, DTF allows for quicker turnaround times and reduced production costs. This advantage is particularly beneficial for businesses that rely on fulfilling custom orders swiftly, enhancing customer satisfaction and loyalty while optimizing operational efficiency.

Versatility Across Industries

One of the hallmarks of DTF transfers is their versatility, which opens doors to a multitude of applications in various industries. Apparel printing, for example, has seen a remarkable transformation with DTF technology, allowing designers to experiment with a variety of fabrics ranging from cotton to synthetic blends. Not only can businesses create customized clothing items, but they can also expand their product lines to include non-apparel items such as tote bags, home textiles, and promotional merchandise.

This flexibility makes DTF an indispensable asset in the custom printing world. Industries that require promotional materials, such as events or corporate branding, can easily leverage DTF technology to produce unique, high-quality products that leave lasting impressions. Thus, the adaptability of DTF printing not only meets diverse consumer demands but also encourages innovation in product offerings.

Quality and Durability of Prints

Quality and durability are paramount when it comes to printing technologies, and DTF transfers deliver on both fronts. Unlike traditional methods that may fade or crack with time, DTF prints are designed to withstand multiple washes while maintaining their vibrancy and integrity. The water-based inks used in DTF printing contribute to the enduring quality of the prints, providing a premium feel that consumers appreciate.

As businesses strive to provide products that meet customer expectations for longevity, DTF printing stands out by offering high-resolution graphics combined with resilience. This not only enhances customer satisfaction but also reduces the need for frequent replacements, allowing brands to build a loyal customer base around reliable, high-quality apparel.

Eco-Friendly Printing Options

The move towards sustainability is a key factor influencing the direction of the printing industry, and DTF transfers are leading the charge with eco-friendly practices. DTF inks are primarily water-based, significantly reducing the environmental impact compared to solvent-based inks typically used in traditional printing methods. As businesses increasingly adopt green practices, switching to DTF printing aligns with the growing consumer preference for environmentally conscious products.

By promoting DTF technology as a sustainable option, companies not only cater to the eco-aware demographic but also enhance their brand image. This commitment to eco-friendly printing solutions can attract a new segment of consumers who prioritize sustainability when making purchase decisions, giving businesses a competitive edge in the modern market.

Future Innovations in DTF Printing

As the custom printing landscape continues to evolve, innovations in DTF technology suggest a dynamic future for the industry. Ongoing enhancements include development of new ink formulations that improve adhesion and wash resistance, as well as advancements in printing equipment that streamline production processes. These innovations not only improve the user experience but also enhance the quality and efficiency of printed products.

In addition to technological advancements, the DTF printing process is becoming increasingly customizable to meet diverse printing needs. As the demand for tailored solutions grows, businesses that incorporate these innovations will not only improve their operational workflow but also position themselves as leaders in the custom printing industry, ready to meet future challenges and consumer demands.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom printing?

DTF Transfers, or Direct-to-Film transfers, are a modern custom printing method that involves printing designs onto a special film. This film is then heat-pressed onto fabrics, allowing for the application of vivid colors and intricate detail across various materials, including cotton and polyester. This technology simplifies the printing process while delivering high-quality apparel printing results.

Why choose DTF Transfers over traditional screen printing for apparel printing?

DTF Transfers offer several advantages over traditional screen printing, including reduced setup times and costs. Unlike screen printing, which requires separate screens for different colors, DTF can seamlessly print multi-colored designs without extensive preparation, making it ideal for short runs and quick turnaround times.

Are DTF Transfers environmentally friendly compared to other printing technologies?

Yes, DTF Transfers are considered to be more eco-friendly due to their use of water-based inks. This reduces the environmental impact compared to solvent-based inks used in traditional printing methods. Businesses that adopt DTF printing can appeal to environmentally conscious consumers while ensuring high-quality printing results.

What materials can I use DTF Transfers on for custom printing?

DTF Transfers are highly versatile and can be applied to a wide range of materials such as cotton, polyester, and spandex blends. This flexibility makes DTF printing an excellent choice for various applications in the apparel printing industry, including t-shirts, hoodies, and promotional items.

How does the durability of prints made with DTF Transfers compare to other printing methods?

Prints made with DTF Transfers are known for their durability and wash resistance. The advanced ink formulations used in DTF printing help ensure that designs remain vibrant and intact even after multiple washes, outperforming many traditional printing methods in durability.

Is DTF Transfers technology easy to use for new businesses in the custom printing industry?

Absolutely! The DTF printing process is user-friendly and requires less technical training compared to traditional methods like screen printing. This accessibility allows new and small businesses to easily incorporate DTF technology into their custom printing operations, enabling them to produce high-quality products without extensive expertise.

| Key Points | Description |

|---|---|

| Versatility in Applications | DTF transfers can be used on a variety of fabrics like cotton, polyester, and spandex blends, making them suitable for many sectors including apparel and promotional products. |

| High-Quality Prints | Produces vibrant colors and intricate details, excelling over traditional methods in delivering high-resolution graphics. |

| Reduced Setup Time and Cost | Faster and more cost-effective than screen printing, allowing for quick and efficient multi-color designs without extensive setup. |

| Environmentally Friendlier Options | Utilizes mainly water-based inks, making it a sustainable choice for eco-conscious consumers. |

| Easy to Use | The DTF process is straightforward and accessible, lowering barriers for small businesses to utilize custom printing technology. |

| Recent Developments | Advancements in ink formulations and printing equipment enhance durability and streamline production, promoting further adoption of DTF technology. |

Summary

DTF Transfers are revolutionizing the custom printing landscape through their impressive versatility and high-quality results. With the ability to print on various fabrics and produce vibrant colors, businesses can cater to diverse consumer demands while maintaining cost efficiency. The eco-friendly nature of DTF inks also aligns with the growing trend of sustainability in printing. As advancements in technology continue to emerge, DTF transfers promise not only to meet current market needs but also to shape the future of custom printing, enhancing both user experience and product quality.