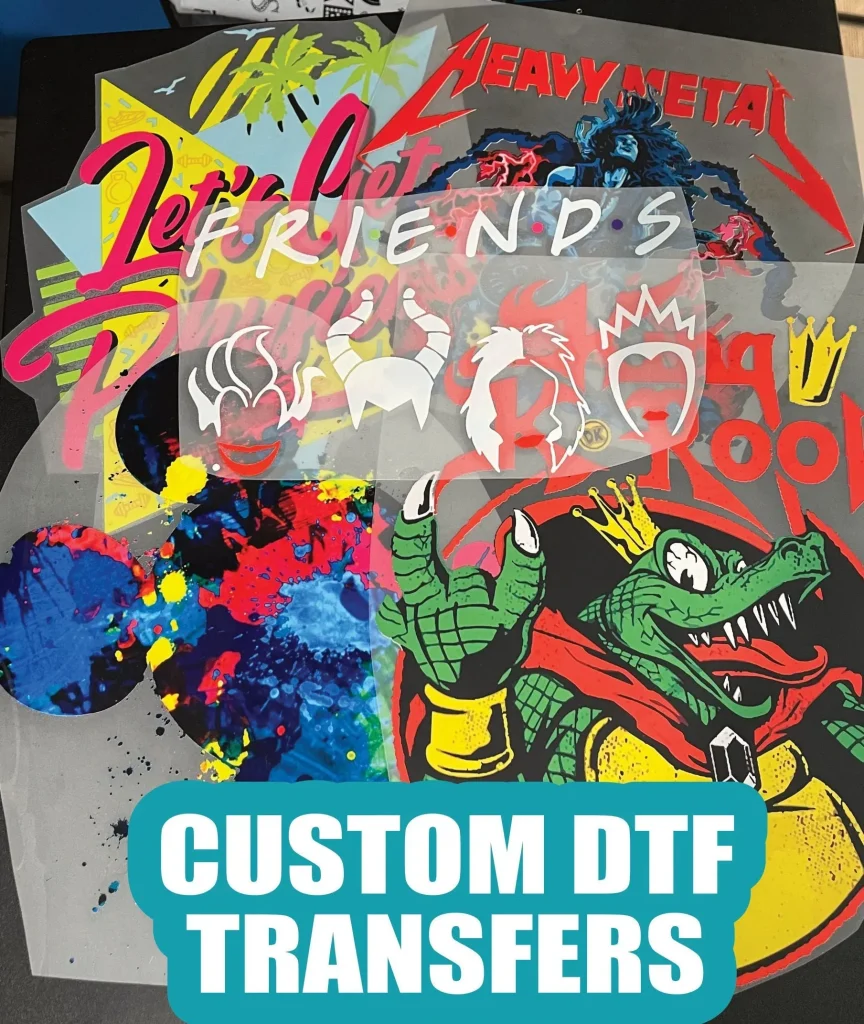

In the vibrant world of custom printing, DTF transfers have emerged as a groundbreaking technique that is transforming the textile industry. With Direct-to-Film printing, businesses can create eye-catching designs that are both high-quality and cost-effective. As small enterprises and entrepreneurs embrace DTF printing techniques, they discover a wealth of possibilities in personalized apparel and promotional products. The advancements in DTF technology have made this method more accessible, allowing for incredible detail and color vibrancy in prints. In this comprehensive guide, we will delve into the essential DTF printing equipment, practical tips for success, and the latest trends shaping this innovative printing landscape.

Direct-to-Film (DTF) methodologies represent a significant leap forward in printing solutions, catering to the diverse needs of those in the apparel industry. This cutting-edge printing approach allows for intricate graphics and bold colors to be effortlessly transferred onto various fabric substrates. By employing advanced DTF printing techniques, businesses can not only produce stunning visual designs but also cater to the growing demand for customized clothing and merchandise. As we explore the realm of DTF transfers, we’ll uncover how technological advancements have streamlined the process, the essential equipment necessary for high-quality results, and tips for maximizing the effectiveness of this versatile printing style.

Understanding DTF Printing Techniques

DTF printing techniques represent a significant leap in the world of garment decoration and textile printing. Unlike traditional methods, such as screen printing, DTF allows for high-quality graphics and vibrant colors on a wide variety of fabrics. The process involves printing designs onto a PET (polyethylene terephthalate) film, which can be easily heat-pressed onto garment surfaces. This facilitates more intricate designs and color gradients without losing sharpness or vibrancy, making DTF an ideal choice for custom printing on apparel.

Moreover, one of the key benefits of DTF printing techniques is their versatility. The method is suitable for many fabric types, including cotton, polyester, and blends, ensuring that brands can cater to diverse market demands. DTF’s adaptability allows businesses to offer personalized and stylish products that resonate with their audience, which is particularly appealing in today’s custom apparel market that thrives on individuality.

The Impact of Advancements in DTF Technology

Recent advancements in DTF technology have transformed the landscape of digital textile printing. The development of eco-friendly inks and improved print head technology has dramatically enhanced both the durability and vibrancy of prints. These innovations not only focus on aesthetic output but also ensure that DTF prints hold up against the rigors of everyday use, such as washing and abrasion. As a result, businesses can confidently offer high-quality products that meet customer expectations for both appearance and longevity.

In addition to ink and printer enhancements, advancements in DTF technology have also led to faster production processes. Commercial DTF printers on the market today are designed with efficiency in mind, allowing for quicker turnaround times without compromising quality. This progress plays a critical role in meeting the ever-increasing consumer demand for custom apparel, providing businesses with the tools they need to thrive in a competitive marketplace.

Key Equipment for DTF Printing Success

To excel in the DTF printing space, having the right equipment is essential. Investing in high-quality DTF printers and heat presses is a must for anyone serious about their custom apparel business. DTF printers specifically engineered for this process guarantee superior outcomes, with features designed to optimize ink flow and minimize waste. Additionally, a reliable heat press that allows precise temperature and pressure settings is crucial for ensuring that designs adhere correctly to fabrics.

Equally important is the quality of the PET films used in the process. The market now offers specialized DTF films that enhance print results and contribute to the longevity of designs once applied. Selecting the right combination of printer, heat press, and film will not only streamline the printing process but also significantly elevate the quality of the final product, enabling businesses to stand out in an increasingly saturated marketplace.

Emerging Market Trends in Custom DTF Printing

The custom DTF printing market is witnessing substantial growth, fueled by an increasing consumer appetite for personalized items. As more consumers seek unique apparel and accessories that reflect their individual styles, businesses are jumping at the opportunity to provide tailored solutions. This trend is not just limited to fashion; organizations are also leveraging custom printing for promotional materials, driving further demand for DTF services.

Moreover, technological advancements have made DTF printing more accessible, reducing the barriers to entry for new businesses. With decreasing costs associated with DTF printing setups compared to traditional methods like screen printing, entrepreneurs are finding it easier to invest in this innovative technology. This shift is likely to spur even more creativity in design and application, as new players enter the market with fresh ideas and diverse offerings.

Practical Strategies for Effective DTF Printing

For optimal results in DTF printing, certain practical strategies can make a significant difference. First and foremost, choosing high-quality films and inks designed for DTF applications is crucial. Not all products on the market offer the same level of performance, so it is worth investing in reliable materials that will yield vibrant colors and durable prints. Additionally, understanding the curing process is essential; precise timing and temperature settings are paramount to ensure strong adhesion and longevity of the design.

It is equally important to maintain your DTF equipment regularly. Consistent cleaning of print heads and nozzles will prevent clogs and ensure smooth operation, maximizing productivity. Experimentation also plays a key role in the creative process; leveraging design software to explore different layouts, colors, and textures can lead to unique offerings that appeal to your target audience. Lastly, conducting test prints before a large run can save time and resources, allowing you to confirm quality and avoid costly mistakes.

Accessing Training Resources for DTF Mastery

As the DTF printing landscape evolves, obtaining the right training is vital to staying ahead of the curve. Many companies offer online workshops tailored to aspiring DTF printers, covering essential topics from foundational techniques to advanced methodologies. Engaging in these educational opportunities allows individuals to hone their skills and build confidence in their abilities, which is essential in an industry that thrives on innovation.

Moreover, online communities and forums dedicated to DTF printing can serve as invaluable resources for both beginners and seasoned pros. These platforms allow users to share tips and experiences, troubleshoot issues, and celebrate successes, providing a support network that can enhance one’s proficiency in DTF techniques. Supplementing formal education with insights from established practitioners ensures you are well-equipped to tackle the challenges in the ever-evolving world of custom printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, short for Direct-to-Film transfers, involve printing designs on a specialized PET film. This process begins with the image printed on the film, followed by applying and curing adhesive powder. Finally, the design is heat-pressed onto fabric, resulting in vibrant and detailed prints suitable for various materials.

What are the latest advancements in DTF technology?

Recent advancements in DTF technology focus on improved print durability and color vibrancy, achieved through enhanced print head technology and eco-friendly ink formulations. Innovations by manufacturers like Epson and Brother provide better quality and efficiency in DTF printing, making it a preferred method for custom apparel.

What equipment do I need for successful DTF printing?

To effectively utilize DTF printing techniques, you will need specialized equipment such as a DTF printer, a reliable heat press for transferring designs, and high-quality PET film specifically designed for DTF applications. This equipment ensures optimal print quality and longevity.

How can I ensure high-quality results with DTF transfers?

To achieve high-quality results in DTF transfers, select premium films and inks, master the curing process by following precise guidelines, regularly maintain your DTF printer, and conduct test prints before large runs. These practices help ensure reliable adhesion and print durability.

What are the benefits of DTF printing for custom apparel?

DTF printing offers several benefits for custom apparel, including the ability to produce intricate designs with vibrant colors on various fabrics. It is a cost-effective solution with lower setup complexity compared to traditional methods, making it ideal for small businesses and entrepreneurs in the custom printing market.

Where can I learn more about DTF printing techniques?

To enhance your skills in DTF printing, take advantage of online workshops, community forums, and YouTube tutorials focused on DTF techniques. These resources provide valuable insights ranging from design principles to effective application methods, helping you master DTF technology.

| Key Point | Details |

|---|---|

| Introduction | DTF transfers are gaining traction in the printing industry due to their versatility and ease of use. |

| What are DTF Transfers? | Printing designs on specialty film that transfers onto fabric, resulting in vibrant, durable prints. |

| Recent Developments | New printer technologies and eco-friendly ink formulations improve durability and color vibrancy. |

| Market Trends | Increased demand for custom apparel is driving growth, resulting in lower costs and setup complexity. |

| Practical Tips for DTF Printing | Choose quality materials, master the curing process, maintain equipment, experiment with designs, and conduct test prints. |

| Essential Equipment | Key components include DTF printers, heat presses, and specialized PET films for optimal results. |

| Training and Resources | Online courses, community forums, and YouTube tutorials offer valuable skills for mastering DTF transfers. |

| Conclusion | DTF transfers provide a leading solution in custom printing, enhancing printing capabilities and efficiency. |

Summary

DTF transfers are revolutionizing the textile printing landscape, offering an innovative and reliable method for creating stunning, long-lasting designs on various fabrics. This advanced technology, paired with the user-friendly process and reduced costs, presents an excellent opportunity for small businesses and entrepreneurs looking to make a mark in the custom printing market. Understanding the critical aspects, such as recent technological advancements, market trends, and essential equipment, is crucial for those aspiring to excel with DTF transfers. By investing in quality resources and ongoing education, users can greatly enhance their printing capabilities, leading to exceptional outcomes in their custom apparel ventures.