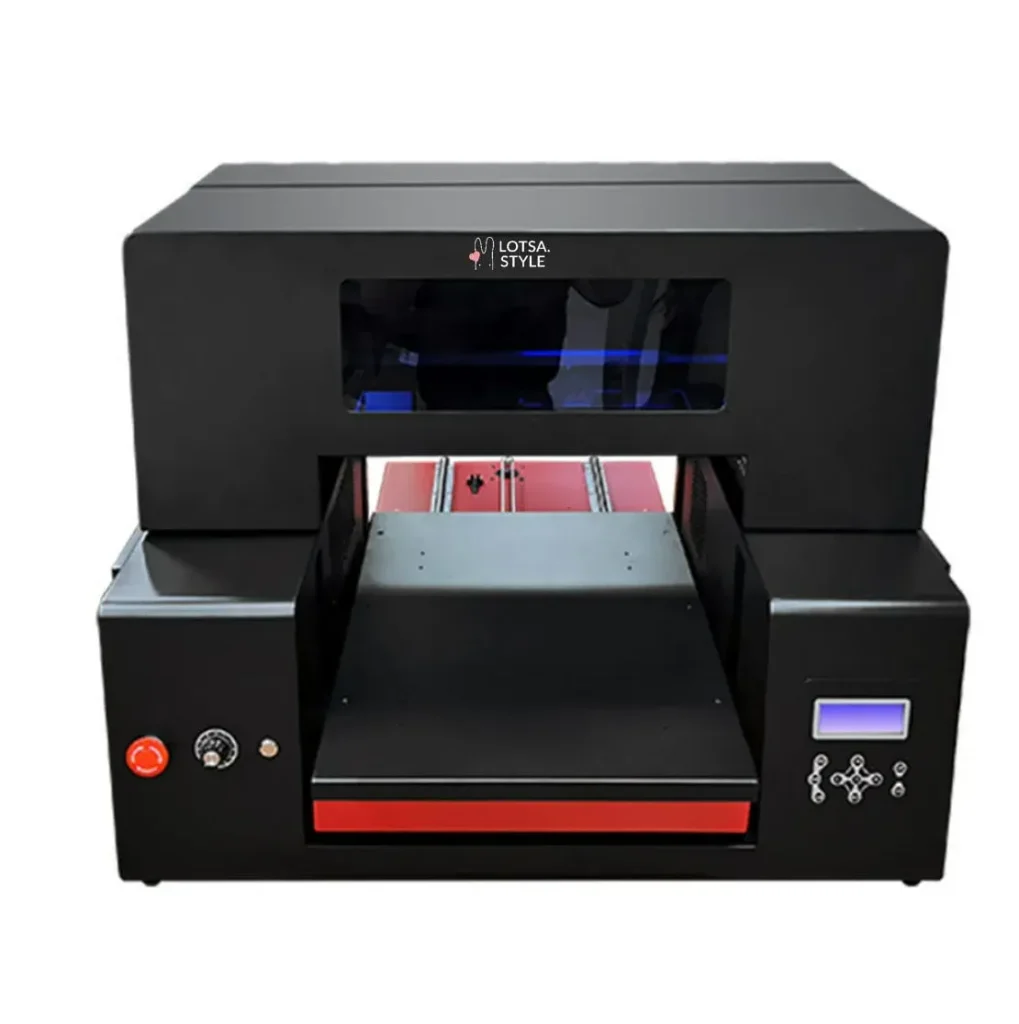

UV DTF printers are revolutionizing the printing industry by offering unparalleled versatility and efficiency in the printing process. By utilizing advanced UV light technology, these printers cure inks instantly, allowing for high-quality, vibrant prints on a variety of materials ranging from fabric to metal. As businesses seek to optimize their workflow, understanding the nuances of UV DTF printing becomes essential for enhancing productivity and quality. This article presents effective strategies for printer calibration and material selection, ensuring that your UV DTF printing operations run smoothly and efficiently. Dive in to discover how to elevate your printing game and achieve impeccable results with these innovative machines.

When we talk about UV DTF technology, we refer to a method that streamlines the process of transferring images to films using UV light for curing. This modern printing solution caters to a wide array of applications, making it easier for companies to print on different materials while maintaining vivid color and detail. Emphasizing the importance of an efficient workflow in the realm of UV DTF, professionals can significantly improve their output quality through effective printer calibration and meticulous material selection. In this exploration, we will delve into best practices that enhance the printing process, including resource optimization and workflow management. By understanding these aspects, you’ll be well-equipped to harness the full potential of UV DTF equipment.

Optimizing Your UV DTF Printing Process

To achieve outstanding results in UV DTF printing, it is essential to optimize each phase of the printing process. This includes everything from selecting the appropriate materials to ensuring that your printer is correctly calibrated. High-quality inks and films specifically designed for UV DTF applications provide better adhesion and vibrant colors, which are crucial for producing stunning prints. To further enhance the efficiency, it’s advisable to conduct pre-printing checks meticulously, such as verifying color profiles and designs to prevent potential errors that could result in wasted materials.

Beyond material selection, understanding the intricacies of the UV DTF printing process can greatly impact your output. Regular calibration of the printer guarantees that colors remain consistent across various jobs. Fluctuations can detract from the visual quality of your prints, so it’s important to keep your printer settings adjusted according to the latest production needs. Reinforcing these practices creates a smoother workflow that not only increases productivity but also ensures that your prints are delivered with the highest quality.

Frequently Asked Questions

What are the key benefits of using UV DTF printers?

UV DTF printers offer several advantages including vibrant print quality, excellent adhesion to various materials, and quick curing processes. These printers utilize UV light to instantly cure inks, ensuring durability and resistance to fading, making them ideal for producing high-quality prints on fabrics, glass, metal, and more.

How important is printer calibration in UV DTF printing?

Printer calibration is crucial for ensuring color accuracy and high-quality prints in UV DTF printing. Regular calibration helps maintain consistent output, preventing color discrepancies and enhancing overall print quality. It’s advisable to calibrate your printer frequently to achieve the best possible results.

What materials are best suited for UV DTF printing?

Choosing compatible materials is essential for UV DTF printing. High-quality films and substrates that are specifically designed for UV DTF are recommended to ensure better adhesion and durability. Using inferior materials can result in peeling, fading, and poor print quality, thereby affecting your brand’s reputation.

What are some efficient workflow tips for UV DTF printers?

To enhance your workflow when using UV DTF printers, consider implementing routine maintenance, ensuring proper printer calibration, selecting the right materials, and providing staff training. Streamlining your printing processes with well-defined protocols also minimizes errors and boosts productivity, leading to high-quality outputs.

How can software improve the UV DTF printing process?

Utilizing quality design software is vital in the print preparation phase of UV DTF printing. It streamlines file management, enhances color accuracy, and reduces common errors that can arise during printing. Good software helps optimize your designs and ensures that all elements are ready for a smooth production process.

What post-processing techniques are essential for UV DTF prints?

Post-processing techniques, particularly curing and finishing, play a significant role in the quality of UV DTF prints. Proper curing using UV light is crucial for enhancing durability and ensuring the longevity of prints. Employing efficient curing systems can significantly improve the final product’s quality and resistance to wear.

| Key Component | Description |

|---|---|

| Proper Setup and Calibration | Calibrating the printer regularly and controlling the environment ensures high-quality color accuracy and print integrity. |

| Material Selection | Choosing high-quality, compatible films and substrates will enhance adhesion and prevent peeling or fading. |

| Print Preparation | Utilizing quality design software and conducting thorough pre-printing checks can minimize errors and waste. |

| Efficient Maintenance | Regular maintenance, including cleaning printer components, prevents downtime and enhances production quality. |

| Training and Workflow Management | Training staff and creating standardized workflows improves operational efficiency and reduces errors. |

| Post-Processing Techniques | Effective curing and finishing processes ensure durability and quality of the final print. |

Summary

UV DTF printers have revolutionized the printing industry by offering unmatched flexibility and print quality. To harness the full potential of these machines, it is crucial to optimize workflows effectively. Key strategies include maintaining regular printer calibration, selecting high-quality materials, implementing thorough print preparation, and scheduling routine maintenance. With a focus on training staff and streamlining operations, businesses can significantly reduce production costs and waste while enhancing print durability. Keeping up with the evolving technology and advancing printing techniques is essential to remain competitive. By following these best practices, your UV DTF printing operation can achieve greater efficiency and impressive results that delight customers.