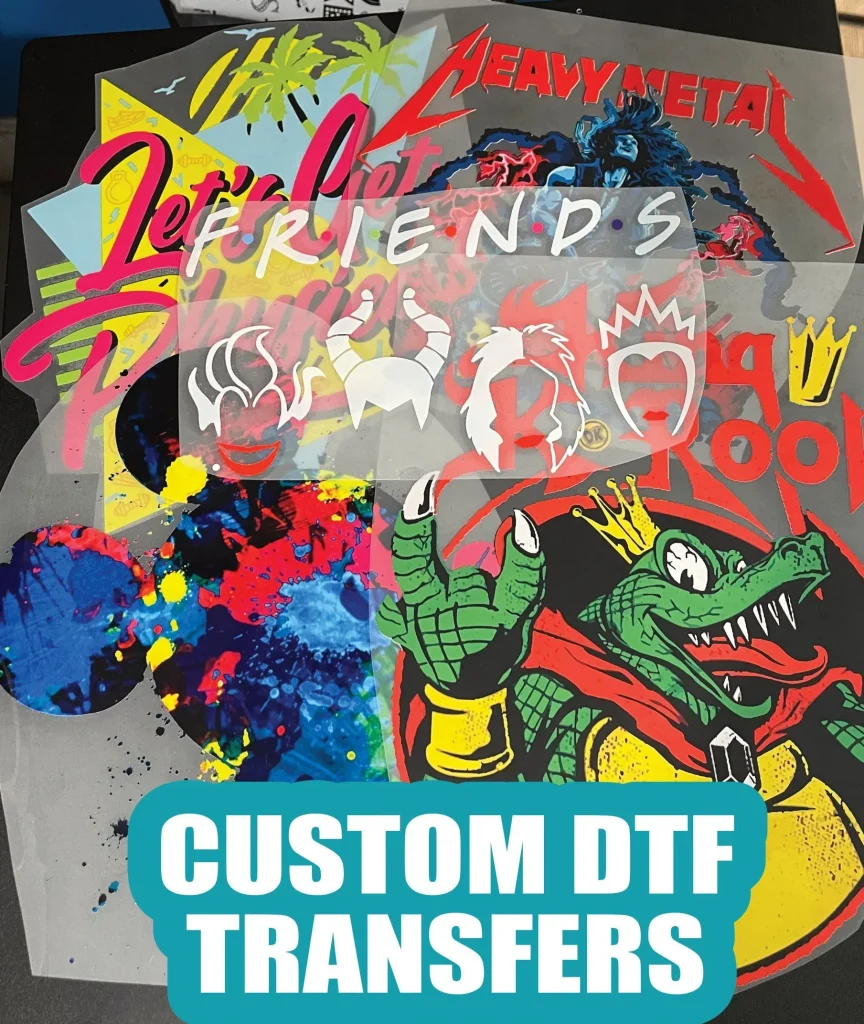

In the vibrant world of textile printing, **DTF transfers**, or Direct-to-Film transfers, have emerged as a revolutionary technology that significantly enhances the fabric decoration process. By utilizing specialized inks printed onto a unique film, DTF transfers allow for exceptional color vibrancy and intricate designs that can easily adapt to various fabric types. This method not only streamlines production processes but also offers businesses a cost-effective solution for custom apparel without compromising quality. As the DTF printing process evolves, its advantages continue to attract entrepreneurs eager to meet the growing demands of personalized products. In this guide, we will delve into the essential aspects of DTF transfers, including their benefits, necessary equipment, and the exciting trends shaping the DTF market.

Direct-to-Film transfers, often known as DTF printing, represent a modern evolution in the fabric decoration landscape. This innovative technique involves printing designs onto a thin film before applying them to textiles through a heat press method. The DTF method distinguishes itself from traditional printing techniques by offering exceptional versatility, efficiency, and durability for a wide range of materials, including cotton and polyester. Not only does this technique cater to the increasing consumer demand for customized clothing, but it also opens up new avenues for businesses within the clothing industry. In this exploration of DTF printing, we will uncover the myriad advantages that make it a staple in contemporary textile applications.

Understanding the DTF Printing Process

The DTF printing process begins with creating a design using graphic design software, allowing artists and designers to customize their artwork based on specific client needs or personal preferences. This creative phase is crucial; it sets the stage for the final product and ensures that the design aligns perfectly with the intended use, whether for apparel, accessories, or promotional items.

After the design is completed, it is printed onto a special DTF film using high-quality, specialized inks designed to provide vibrant colors and durability. The ink used in the DTF printing process is important as it is formulated to ensure a smooth transfer and longevity of the print after it has been applied to the fabric.

Key Equipment for Successful DTF Transfers

To execute DTF transfers effectively, the right equipment is vital. A specialized DTF printer is at the core of the setup, capable of handling various media types and producing high-quality prints. Alongside the printer, DTF film plays a crucial role, as it must withstand high heat while allowing for clear, vivid designs to be transferred onto fabric.

In addition to the DTF printer and film, a heat press is essential for applying the right amount of pressure and temperature during the transfer process. This equipment ensures that the adhesive bonds effectively with the fabric, guaranteeing that the design remains intact even after multiple washes.

Benefits of Choosing DTF Transfers

DTF transfers offer numerous advantages that make them a favored choice in the textile printing industry. One significant benefit is their versatility; they can be used on various fabrics including cotton, polyester, and leather, allowing businesses to cater to a broad market with custom products ranging from t-shirts to bags.

Moreover, DTF printing is known for its color vibrancy. The inks used in this process yield bright, detailed designs that can include gradients and intricate artwork, capturing the attention of customers and making products visually appealing.

The Durability of DTF Transfers

Durability is another key advantage of DTF transfers, as they are known to resist cracking, fading, and peeling over time. This feature is particularly beneficial for apparel manufacturers who want their products to withstand regular wear and tear while maintaining their aesthetic quality.

Additionally, garments printed with DTF technology are likely to hold up even after multiple washes, making them a reliable choice for businesses that prioritize long-lasting designs. This durability translates into customer satisfaction and repeat business, as consumers appreciate products that look good and endure.

Current Trends in the DTF Market

The DTF transfer market is experiencing notable growth, driven by increasing demand for customization and unique design options among consumers. Businesses are recognizing the potential of DTF printing to cater to this demand efficiently and affordably, leading to an uptick in production using this technology.

Another prevailing trend is the advancement of technology associated with DTF printing. Continuous improvements in printers, inks, and films contribute to better print quality and faster turnaround times, enabling businesses to keep pace with market trends and customer expectations.

Optimal Techniques for DTF Transfer Applications

To maximize the effectiveness of DTF transfers, it’s essential to pay close attention to the application techniques involved. Proper settings in terms of heat and pressure during the transfer process are crucial for optimal results. This involves finding the right balance that allows the adhesive to bond without damaging the fabric or the print.

In addition to the application techniques, regular maintenance of the equipment used in DTF printing is important. Keeping printers and heat presses in top condition helps ensure consistent quality and reliability, ultimately leading to higher customer satisfaction and a successful business model.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then applied to fabric using heat and pressure. This process utilizes specialized inks that create vibrant, detailed images that adhere well and last through multiple washes.

What are the main advantages of using DTF transfer printing?

The advantages of DTF transfers include versatility in fabric compatibility, vibrant color output, durability against fading and cracking, cost-effectiveness for short production runs, and fast turnaround times, making them ideal for custom apparel.

What equipment is necessary for DTF transfer printing?

Essential DTF transfer equipment includes a DTF printer, heat press, DTF film, DTF powder adhesive, and high-quality inks. Each component is crucial for achieving high-quality, long-lasting prints.

How does the DTF printing process differ from traditional printing methods?

The DTF printing process differs from traditional techniques by using a film as a medium for printing, allowing for detailed and colorful designs that can easily be transferred onto various fabrics. This method is generally more efficient for intricate designs compared to DTG or screen printing.

What are the current market trends in DTF transfers?

Current market trends in DTF transfers include technological advancements in printing equipment, increasing demand for customization in apparel, and a focus on eco-friendly practices, such as using sustainable inks and films to meet consumer expectations.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, leather, and blends, making them suitable for many different types of clothing and products.

| Key Points | Details |

|---|---|

| What is DTF Transfer? | A modern printing technique where designs are printed on film and then transferred to fabrics using heat and pressure. |

| Technology Behind DTF Transfers | Utilizes specialized inks for vibrant colors and durability, suitable for various fabrics. |

| Advantages of DTF Transfers | Versatile, produces vibrant colors, durable, cost-effective for small runs, and allows for fast production turnaround. |

| Equipment Needed | DTF printer, DTF film, powder adhesive, heat press, and quality inks. |

| Printing Process Overview | Involves design creation, printing on film, adhesive application, curing, and finally transferring to fabric. |

| Market Trends | Growth driven by technological advancements, demand for customization, and eco-friendly practices. |

Summary

DTF transfers are rapidly becoming a favored technique in the textile printing industry because of their unique advantages. This technology not only allows for exceptional color vibrancy but also offers the versatility to apply designs on various fabric types. As businesses leverage the benefits of DTF transfers, including durability and cost-effectiveness, the market is witnessing a significant shift towards this innovative approach to custom printing. Understanding the process, necessary equipment, and market dynamics will empower creators and entrepreneurs to enhance their product offerings and meet the evolving demands of consumers.