DTF transfers, or Direct-to-Film transfers, have transformed the way custom apparel is designed and printed, enabling fashion enthusiasts and professionals alike to create vibrant designs like never before. This cutting-edge printing technique allows for high-quality, eye-catching graphics that can be easily applied to fabric with the right heat press. In this informative guide, we will delve into the fascinating world of DTF printing, exploring the intricacies of transfer techniques and how they enhance garment aesthetics. Whether you’re looking to add flair to your clothing line or simply create unique pieces for personal use, understanding DTF transfers opens up new avenues for creativity. Join us as we uncover the steps to achieving stunning designs that hold up to the wear and tear of everyday use.

Direct-to-Film printing, often referred to as DTF technology, is a revolutionary method in the textile industry that allows for vibrant and durable designs on fabrics. This innovative process utilizes a special film to transfer intricate designs onto custom clothing items, ensuring high-quality results that can withstand numerous washes. With its combination of advanced transfer techniques and heat application, DTF printing provides artists and marketers with the tools to produce breathtaking apparel that stands out in the market. As the demand for customization in the fashion world increases, understanding this technique becomes essential for anyone looking to make a mark in the industry. Let’s dive deeper into the world of DTF transfers and discover how to implement this exciting technology in your design projects.

What are DTF Transfers?

DTF transfers, or Direct-to-Film transfers, are an innovative printing method revolutionizing how custom designs are applied to fabrics. This process involves printing your design onto a special film that has an adhesive layer, allowing for a vibrant transfer that adheres well to various types of textiles. With a DTF printer, the quality of the prints rivals even the most traditional methods, providing flexibility in terms of design complexity and color vibrancy.

Compared to other transfer techniques, DTF printing stands out due to its ability to yield high-definition prints that are not only vivid but also durable. The bond formed between the print and the fabric during the heat transfer ensures that the design retains its integrity through multiple washes. As a result, DTF transfers are an excellent choice for custom apparel, offering an appealing solution for both small-scale and large-scale production.

Creating Vibrant Designs with DTF Printing

To create stunning designs suitable for DTF transfers, starting with high-quality artwork is crucial. Using graphic design software like Adobe Illustrator enables designers to manipulate their images creatively. Artists should focus on utilizing vibrant colors and detailed patterns that can burst to life when printed. Employing techniques such as adjusting contrasts and utilizing various layers will enhance the overall appearance of the design, ensuring it stands out once transferred to apparel.

Furthermore, it’s essential to prepare your design for the specific properties of DTF printing. Ensuring that images are set to the correct dimensions and resolution—ideally 300 DPI—will lead to sharper and more colorful prints. Color mode adjustments to RGB also play a significant role in achieving the optimal output for transfer, allowing the vibrant hues to manifest beautifully on the fabric.

Essential Tools for DTF Transfer Success

For successful DTF transfers, certain equipment and materials are essential. A dedicated DTF printer is necessary to produce high-quality prints directly onto transfer film. Alongside the printer, you will need DTF powder adhesive, a heat press, and appropriate transfer films. Investing in quality tools can streamline your workflow and enhance the quality of your printed designs, yielding professional results.

In conjunction with a reliable printer, a quality heat press is vital for achieving the right temperature and pressure required to transfer designs effectively. This equipment helps fuse the design onto the fabric, ensuring durability and vibrancy in the finished product. By carefully selecting tools suited for DTF printing, you can save time and reduce errors throughout the process.

Caring for Your DTF Equipment

Maintenance is critical when working with DTF transfer equipment to ensure consistent high-quality outputs. Regularly cleaning your DTF printer and heat press can significantly reduce the likelihood of issues such as clogged print heads or inconsistent heat distribution, which can negatively affect print quality. Implementing a strict maintenance schedule helps prolong the lifespan of your equipment and preserves the integrity of your designs.

Additionally, ensure that the heat press is checked for any wear and tear, and maintain proper calibration to prevent variations in temperature during transfers. This attention to detail not only improves the overall production process but also enhances the final appearance of your custom apparel, ensuring that vibrant designs look their best for years to come.

Choosing the Right Fabrics for DTF Transfers

The selection of fabric plays a pivotal role in how your design will ultimately look when using DTF transfers. Fabrics that are a blend of cotton and polyester tend to yield the best results, allowing colors to remain bright and true. Understanding fabric characteristics can help you choose materials that maximize the potential of your designs, ensuring that they maintain their vibrancy and durability even after numerous washes.

Moreover, it’s vital to consider the texture and weight of the fabric when preparing for DTF printing. Heavier, smoother fabrics typically allow for better adherence of the design, helping to avoid issues such as peeling or fading. Researching which fabrics work best with DTF methods will provide you with a competitive edge in the custom apparel market, enabling you to deliver high-quality products every time.

The Future of DTF Technology

As we move into 2024, the advancements in DTF transfer technology are paving the way for more efficient processes and higher quality results. Innovations in transfer materials and ink formulations are enhancing the vibrancy of prints while improving washability and durability. This evolution means that designers and manufacturers can expect even better performance from their DTF operations, allowing for more creative possibilities in custom apparel.

Furthermore, as the industry continues to evolve, staying updated with the latest trends and technologies will be crucial for maintaining a competitive advantage. Understanding emerging techniques, such as new transfer materials or software advancements, can significantly improve your ability to produce high-quality, vibrant designs that capture consumers’ attention in an ever-growing market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique where vibrant designs are printed onto a special film before being heat transferred onto fabric. The process involves printing your design, applying a powdered adhesive, curing it with heat, and then using a heat press to transfer the design onto the fabric.

How can I create vibrant designs using DTF printing?

To create vibrant designs with DTF printing, start with high-resolution graphics software to design artwork in RGB color mode. Use contrasting colors and layers for better depth. After printing the design onto transfer film, ensure to properly cure the adhesive before transferring it to your chosen fabric using a heat press.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer numerous advantages for custom apparel, including high-quality vibrant prints, flexibility in design, and compatibility with a wide range of fabrics. Unlike traditional methods, DTF allows for detailed designs and easy application on varied apparel types, making it a popular choice in fashion customization.

What types of fabrics work best with DTF transfers?

Fabrics that yield the best results with DTF transfers include cotton, polyester blends, and various types of synthetic fabrics. These materials accept the printed designs well, ensuring that the colors remain vibrant and durable after washing.

What is the curing process in DTF transfer techniques?

The curing process in DTF transfer techniques involves applying heat to the printed transfer film to melt the adhesive into the ink, allowing for a strong bond when the design is transferred to fabric. This step is critical, as it ensures the design will adhere properly and withstand multiple washes.

How do I maintain my DTF printing equipment for optimal results?

To maintain your DTF printing equipment, regularly clean the printer and heat press, follow maintenance schedules, and check for any wear in components. Proper upkeep ensures consistent quality output and prevents issues during the printing and transfer processes.

| Key Steps | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers involve printing designs onto a special film that is then transferred onto fabric using heat, resulting in vibrant and durable prints. |

| Preparation: Design Creation | Choose your graphic software, set dimensions in RGB mode, and ensure high resolution for clarity. Tips include using contrast and layers. |

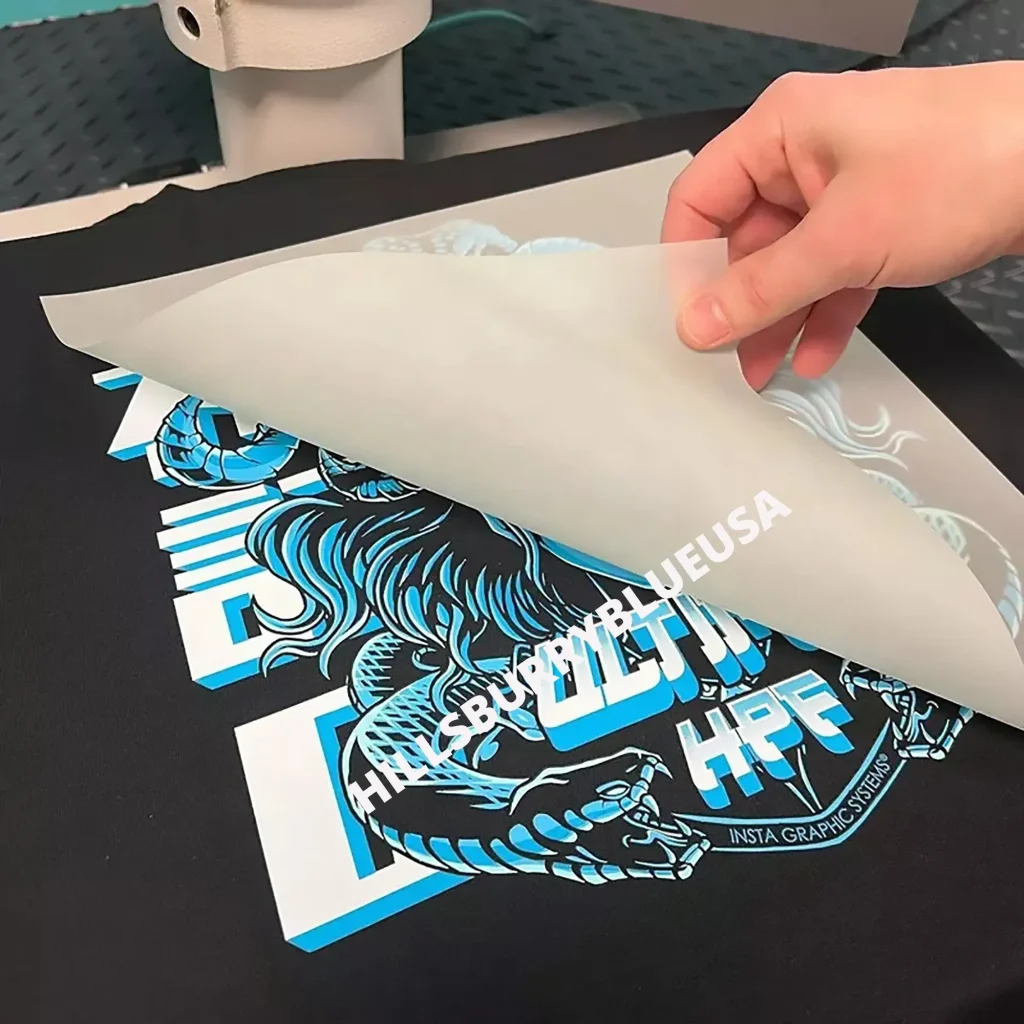

| Step-by-Step Process | 1. Print the Design 2. Cure the Print 3. Transfer to Fabric 4. Peel Away the Film 5. Final Touches |

| Enhancing Vibrancy and Quality | Ensure color calibration, choose the right fabric, and maintain your equipment for the best results. |

| Recent Developments | Advancements in DTF technology have improved vibrancy and durability and expanded fabric compatibility. |

Summary

DTF transfers have revolutionized the realm of custom textile printing, offering creators the tools to craft vibrant and lasting designs with ease. By adhering to the outlined steps—from design creation to the transfer process—individuals can produce stunning prints that not only catch the eye but also endure the test of time. With continued advancements in technology and an ever-expanding range of applications, DTF transfers are an excellent choice for anyone looking to elevate their fabric design projects.