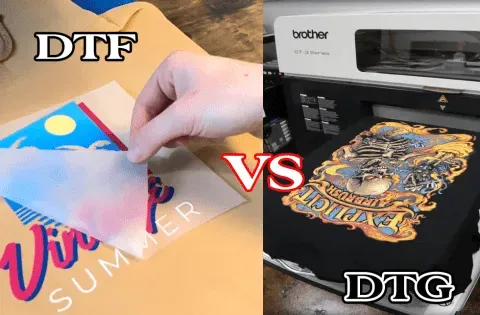

DTF transfers vs DTG is a decision many apparel brands face when choosing how to decorate garments today. For a quick view, the DTF vs DTG comparison highlights where each method excels, depending on fabric and production needs. DTF transfers advantages include strong color saturation and compatibility with a wide range of fabrics, while DTG printing quality can deliver a softer hand and delicate gradients on suitable textiles. Understanding the cost of DTF vs DTG for different order sizes helps planners forecast timing, budgeting, and return on investment. By aligning your design goals with fabric choices and production realities, you can pick the most reliable approach for your apparel line.

In other terms, think of digital textile transfers as a film-to-fabric process and direct-to-garment printing as on-fabric ink deposition, two complementary garment decoration techniques with distinct advantages. When you frame the decision through broader design considerations, you can weigh factors like wash durability, hand feel, and color fidelity across fabrics. This LSI-inspired framing helps designers see that the underlying choice is about how best to transfer artwork onto cotton, blends, or synthetics, whether with heat-activated films or direct ink deposition. Evaluating supply chain factors, turnaround times, and maintenance requirements complements the traditional method comparison and supports a clear, customer-ready explanation. In short, a thoughtful, multi-angled view helps teams select the most effective approach for each project while keeping options open for future collections.

DTF transfers vs DTG: A Clear Guide to the Core Differences

DTF transfers and DTG printing are two popular methods for apparel decoration, each with its own strengths. Understanding the core differences helps in the DTG vs DTF comparison and sets expectations for fabric compatibility, hand feel, and durability.

DTF transfers involve printing a design onto a film, applying an adhesive powder, curing, and transferring the image to fabric with heat. DTG printing, by contrast, applies ink directly to the garment using water-based inks and usually requires pretreatment on darker fabrics. These foundational distinctions drive how each method performs in real-world projects and influence decisions about color fidelity, texture, and wash durability.

DTF transfers advantages: Versatility, durability, and faster setup

DTF transfers advantages include broad substrate compatibility and strong color saturation across a wide range of fabrics. Because the transfer uses a film and adhesive, it can be applied to 100% cotton, cotton blends, poly blends, and even some synthetics with reliable results. This versatility makes DTF a practical choice for high-mix, low-volume runs where garment colors vary.

Additionally, DTF tends to be less sensitive to pretreatment variations and can reduce setup changes when colors or garment colors differ within a batch. The durable bond from the adhesive layer helps products hold up under repeated washing, and the process often delivers robust results on darker fabrics where other methods struggle.

DTG printing quality: Soft hand, color fidelity, and limitations

DTG printing quality shines when soft hand feel and delicate color gradients matter. Direct-to-garment ink sits within the fabric, producing a smooth, breathable layer on appropriate fabrics and light-colored garments. With premium pretreatment and calibrated printers, DTG can deliver subtle shading and high color fidelity for intricate designs.

However, DTG can face challenges on darker fabrics without pretreatment and white underlayers, which adds steps and cost. The hand feel can be exceptionally soft on suitable fabrics, but variations in fabric type and maintenance can influence long-term durability and wash performance in a DTG printing quality assessment.

Cost considerations: cost of DTF vs DTG and long-term ROI

Cost analysis is a central part of the DTG vs DTF decision. Upfront, DTG requires a dedicated printer, pretreatment equipment, and ongoing maintenance, often resulting in higher initial capital expenditure. DTF setups can be more cost-efficient for smaller shops or those handling a variety of designs because you print films in batches and reuse them, reducing per-unit handling.

Ongoing consumables also differ: DTG relies on inks, pretreatment liquids, and occasional maintenance, while DTF involves film, adhesive powder, curing, and the same heat-transfer equipment. When evaluating the cost of DTF vs DTG, consider order mix, fabric variety, design complexity, and expected throughput to estimate long-term ROI and unit economics.

Best print method for apparel: Aligning fabric, volume, and color goals

Best print method for apparel decisions hinge on fabric types, color requirements, and production volume. For broad fabric compatibility and mixed-color runs, DTF transfers may offer predictable results without extensive pretreatment variables. If your catalog features a lot of dark garments or diverse textiles, DTF can simplify production while delivering durable finishes.

Conversely, for soft-hand designs on light fabrics with high color fidelity, DTG may be preferable, especially where long runs of a consistent design are involved. This is where a DTG vs DTG comparison becomes a factor in scale and consistency. The best approach often combines both methods: using DTF for high-mix, multi-fabric items and reserving DTG for specialized, soft-hand designs on compatible fabrics.

Practical decision framework: testing, samples, and stakeholder communication

To implement a practical decision framework for choosing between DTF transfers and DTG, start with clear project requirements: fabric types, color needs, and expected order volume. Run small test batches on your most common fabrics to evaluate color accuracy, hand feel, and adhesion quality, and compare results using real garment samples.

Communicate outcomes with clients or internal stakeholders by detailing how each method aligns with fabric choices, lead times, and durability expectations. Sharing test outcomes and transparent cost considerations builds trust and helps everyone understand why a particular method was selected for a given order.

Frequently Asked Questions

DTF vs DTG comparison: which method is best for high-color-detail designs across diverse fabrics?

In a DTG vs DTF comparison, the best choice depends on fabric and color complexity. DTG printing quality shines on light fabrics with soft hand and smooth gradients, while DTF transfers deliver strong color, broad fabric compatibility, and durable results on dark garments. For ultra-dense, multi-color designs on mixed fabrics, DTF transfers are typically more reliable, whereas DTG is ideal for a soft hand on compatible fabrics.

DTF transfers advantages: what are the key benefits of DTF transfers over DTG?

DTF transfers advantages include broad fabric compatibility (cotton, blends, and some poly fabrics), strong durability, and consistent results across dark and light garments. They also reduce pretreatment steps and are cost-effective for high-mix, low-volume runs, with easier setup when changing designs.

DTG printing quality: how does DTG printing quality compare to DTF transfers?

DTG printing quality excels in fine detail and color gradients on suitable fabrics, delivering a soft hand on light garments. Dark fabrics require pretreatment and white underbases, which adds cost and steps, and durability can vary with laundering. For soft feel and high-resolution artwork on compatible fabrics, DTG often leads.

Cost of DTF vs DTG: how do upfront and per-unit costs compare for these methods?

Cost of DTF vs DTG depends on order size, fabric type, and color complexity. DTG typically has higher upfront costs for printers and pretreatment equipment, but can offer lower per-unit costs on long runs of a single design on compatible fabrics. DTF usually provides lower initial investment and faster changeovers for high-mix jobs, with film-based workflow reducing handling.

Best print method for apparel: when should you choose DTF transfers vs DTG for your line?

Best print method for apparel depends on fabric type, color needs, and volume. For broad fabric compatibility, fast turnarounds, and multiple colors across garments, DTF transfers are often the better fit. For ultra-soft hand feel and high color fidelity on light fabrics with consistent orders, DTG can be the preferred method. Use a structured decision framework and test prints to confirm.

DTF transfers vs DTG: turnaround times and workflow considerations?

DTF transfers vs DTG turnaround can vary: DTG can be faster for simple, single-color designs on pretreated light fabrics, while DTF excels in high-mix, low-volume environments by batching films and applying them as needed. Your workflow, including file prep, curing, and quality checks, will determine bottlenecks. Plan batches, run tests, and optimize lead times for each project.

| Factor | DTF Transfers | DTG (Direct-to-Garment) | Key Takeaway / Best Use |

|---|---|---|---|

| Artwork and color complexity | Versatile across fabrics; strong color blocks with robust durability when cured; handles dense color blocks well | Excellent for high color counts and gradients on light fabrics; modern DTF has closed the gap in vibrancy; pretreatment not usually required | Choose based on fabric type and desired hand feel: DTF for mixed fabrics; DTG for detailed gradients on light fabrics |

| Fabric compatibility and color options | Broad substrate compatibility: 100% cotton, blends, poly blends, some polyesters; fewer fabric-color constraints | Best on light fabrics; darker fabrics require pretreatment, white underbase, and color management | DTF offers edge in mixed-material runs; DTG excels on light fabrics with proper pretreatment for darker tones |

| Durability and wash performance | Strong durability across many fabrics due to adhesive film bond; robust on darker garments | Excellent washfastness when properly pretreated and cured; performance varies with fabric and care | DTF tends to be more consistently durable across fabrics; DTG requires proper care and pretreatment for long-term wash durability |

| Soft hand and texture | Film/adhesive can feel slightly plasticky on some fabrics; hand feel may vary by post-processing | Very soft hand when done correctly; ink sits in the fabric on light fabrics; can feel smoother with pretreatment and calibration | If soft hand is priority, DTG is typically preferred on suitable fabrics; DTF is great for bold, durable finishes |

| Setup, cost, and throughput | Lower upfront costs; reuse printed films; less garment handling between steps; cost per unit varies with design and color blocks | Higher upfront equipment costs (DTG printer, pretreatment, maintenance) and ongoing consumables; cost-per-unit favorable for long runs on light fabrics | DTF is often more cost-efficient for small-to-mid volumes and mixed fabrics; DTG can be economical for long runs of a single design on compatible fabrics |

| Turnaround times and workflow | Efficient for high-mix, low-volume runs when batches of films are prepared; less rework for different garment colors | Can be faster for single-step production on light fabrics when garments are pretreated; relies on print quality and drying/curing steps | Map the full workflow to identify bottlenecks; both methods benefit from batch planning and clear post-processing steps |

| Practical decision framework (how to choose) | Define fabric and color requirements; DTF for broad fabrics, DTG for cotton/light fabrics with soft hand | Define project volume/variability; DTF for high-mix/low-volume; DTG for large, uniform runs on compatible fabrics | Test & scale; run small batches to validate color, texture, and durability before scaling up |

Summary

Conclusion: DTF transfers vs DTG is not a one-size-fits-all decision. The best method depends on fabric types, design complexity, order volumes, and the desired customer experience. By weighing durability, hand feel, color reproduction, and production economics, you can select the method that best aligns with your project goals. In practice, many teams optimize results by using DTF transfers for high-volume, mixed-fabric orders and DTG for specialized, soft-hand designs on compatible fabrics. Regardless of path, a structured testing phase, clear production guidelines, and ongoing evaluation will help ensure consistently high-quality apparel outcomes.