DTF transfers process today underpins how designers move a concept from a digital file to a finished, wearable product. When this process is streamlined, teams can reduce lead times, lower waste, and deliver vibrant, durable prints. In this guide, we explore how to optimize each stage—from design decisions to final delivery—and align with the DTF transfer workflow and DTF design to delivery to keep teams aligned. Color management, film printing precision, and powder application all contribute to consistent results. You’ll also find Direct-to-film printing tips and DTF printing best practices woven through practical steps that boost quality and customer satisfaction.

Viewed through a film-based transfer lens, the journey from digital design to garment is a carefully staged production pipeline. This design-to-fabric pathway relies on color-accurate prepress, calibrated substrates, and precise heat and pressure settings to maintain fidelity. A robust approach covers every function from artwork prep to the final coating and film latch, using checks and balances that mirror an industrial print run. By framing the topic with related terms such as substrate compatibility, color management, and curing cycles, we align with Latent Semantic Indexing principles and help readers connect ideas across related topics.

DTF transfers process: From concept to customer

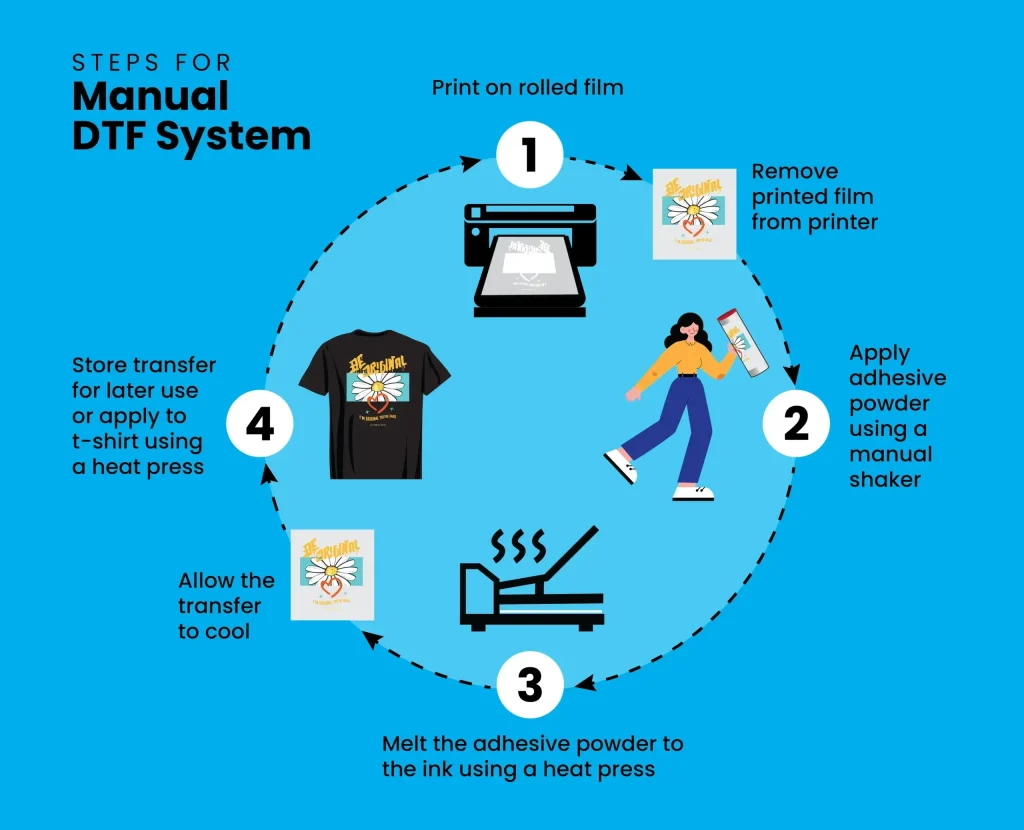

The journey of a garment from concept to customer hinges on a precise, repeatable DTF transfers process. By breaking the job into four core phases—design and color management, film printing and powdering, curing, and the final transfer onto fabric—teams gain predictability and control over outcomes. A well-defined workflow helps maintain color fidelity, adhesion, and durability from order to order, regardless of quantity.

Adopting a streamlined DTF transfer workflow reduces lead times and waste while enabling scalable production. When the transfers process is standardized, teams can quickly identify bottlenecks, align on approval checkpoints, and implement consistent result checks that protect quality across batches. This is the foundation for delivering vibrant, durable prints that keep customers coming back.

DTF Design to Delivery: Aligning Creative and Production

DTF design to delivery centers the creative brief within the limits of production. Designers should anticipate print constraints, color separations, and fabric compatibility from the outset, using pre-approved templates, swatches, and color references to minimize revisions. This alignment is essential for predictable results and faster turnarounds.

From file prep to final output, DTF design to delivery emphasizes standardized processes and collaboration between design and production teams. High-resolution graphics, embedded fonts, and color-space conversions should be part of the routine, with clear approval checkpoints and proofing steps to catch color shifts early.

DTF Transfer Workflow: Design to Production

A streamlined DTF transfer workflow starts with design readiness and ends with a finished garment on the customer’s rack. Early decisions about print constraints, color separations, and fabric compatibility reduce back-and-forth and keep the project on schedule. A repeatable sequence—completed with built-in checkpoints—drives consistency across orders.

Quality control should be woven into every stage of the DTF transfer workflow. From file validation and color management to powdering, curing, and transfer, quick checks help catch issues before they scale. When a fault is detected, trace the root cause—printer calibration, ink flow, powder adhesive, or curing timing—and apply targeted adjustments to future runs.

DTF Printing Best Practices and Quality Control in Action

DTF printing best practices focus on reliable color, sharp edges, and durable adhesion. Regular printer maintenance, calibrated profiles, clean workspaces, and documented settings for each material ensure consistency. A disciplined approach to color management and resistance to drift helps keep on-press results aligned with design expectations.

Quality control becomes a continuous discipline rather than a one-off check. Visual checks for color consistency, edge definition, and powder distribution should occur at multiple points—after printing, after powdering, after curing, and after transfer. A simple, repeatable checklist empowers operators, makes deviations traceable, and supports ongoing improvements to the DTF transfer workflow.

Direct-to-Film Printing Tips: Equipment, Materials, and Setup

Direct-to-film printing tips emphasize using high-quality transfer film, compatible inks, and properly calibrated powders. Clean print heads, stable ink delivery, and consistent film handling reduce edge artifacts and misregistration. The right combination of film quality and powder type sets the foundation for a strong bond and long-lasting prints.

Optimizing the material mix and process parameters is key. Tailor heat press settings to fabric type and pigment load, validate residue-free transfer through small test prints, and monitor substrate compatibility. Regular checks on powder spreading equipment help prevent clumps and uneven adhesion, while binding timing and temperature calibrations support durable transfers.

Troubleshooting & Continuous Improvement for DTF Operations

DTF transfer quality control is the backbone of reliable production. When issues like misregistration, color fade, or adhesion problems arise, a structured diagnostic approach helps identify whether the fault lies in design, printing, powdering, curing, or transfer. Documenting anomalies and corrective actions preserves learning for future runs.

A culture of continuous improvement relies on data collection and bottleneck analysis. Regular reviews of printer profiles, ink batches, powder lots, and heat press settings enable proactive adjustments and cycle-time reductions. By refining the DTF transfer workflow through measurement and feedback, teams stay competitive in a fast-evolving market while delivering consistent, high-quality results.

Frequently Asked Questions

What is the DTF transfer workflow within the DTF transfers process from design to delivery?

The DTF transfer workflow in the DTF transfers process breaks design readiness, file preparation, film printing, powdering, curing, and fabric transfer into a repeatable sequence with built-in checkpoints. Standardizing these stages improves predictability, preserves color fidelity, and reduces lead times from concept to customer.

How does DTF transfer quality control fit into the DTF transfers process?

Quality control is integrated at every phase of the DTF transfers process. Perform quick checks after printing, after powdering, after curing, and after transfer to verify color accuracy, edge definition, and adhesion. If issues arise, identify root causes—printer calibration, ink flow, powder distribution, or curing timing—and adjust the workflow accordingly.

What are DTF printing best practices for reliable results in the DTF transfers process?

DTF printing best practices include using high-quality transfer film, calibrated printer profiles, appropriate print resolution and ink limits, and thorough color management. Maintain clean nozzles, consistent film handling, and validate color with small test prints before full runs to support a stable DTF transfers process.

What direct-to-film printing tips help improve outcomes in the DTF transfers process?

Direct-to-film printing tips include keeping film clean, using inks that match the film and powders, calibrating the printer for color accuracy, and inspecting bonding powder distribution. Tailor heat press settings to fabric type and pigment load, and perform routine maintenance to ensure vibrant, durable results within the DTF transfers process.

How can you optimize the DTF design to delivery in the DTF transfers process to reduce waste and lead times?

Optimization starts with design readiness: pre-approved templates, color references, and clear file prep guidance; embed fonts and convert colors to the printer’s color space. Run small proof prints (soft and hard proofs), maintain design-to-delivery standards, and implement standardized packaging and labeling to speed fulfillment in the DTF transfers process.

What should be included in a DTF transfer quality control checklist before shipping in the DTF transfers process?

A DTF transfer quality control checklist before shipping should verify print-to-design alignment, batch color consistency, and adhesion on fabric. Include a final product check, sample tests from each batch, and proper packing and labeling (order ID, substrate, heat settings, aftercare). Recording anomalies and applying corrective actions ensures continuous improvement in the DTF transfers process.

| Aspect | Key Points |

|---|---|

| DTF transfers process overview | Four core phases: design and color management; film printing and powdering; curing and finishing; transfer to final substrate. Standardizing these steps yields predictability and control. Color management is critical; color drift can occur due to printer profiles, material differences, and ambient conditions. |

| Design readiness and file preparation | Designers consider print constraints, color separations, and fabric compatibility from the outset. Use pre-approved templates, swatches, and color references to maintain consistency. File prep should use vector or high-resolution raster graphics, embed fonts, and convert colors to the printer’s color space. Set correct print resolution, ink limits, and layer order. Run a small test print to validate color accuracy and residue-free transfer. |

| Printing, powdering, and curing | Printing onto film should yield clean edges, stable color, and minimal misregistration. Apply bonding powder evenly to maximize grip; inconsistent powder causes poor adhesion. The curing step locks in the powder and stabilizes the film before bonding to fabric. Quality control involves visual checks for color consistency, edge definition, and powder distribution; identify root causes (calibration, ink flow, powder adhesive, or curing timing) and adjust as needed. |

| Packaging, inspection, and shipping | Protect the transfer film from dust, humidity, and light; ensure proper cooldown and templated packing. Label with order ID, substrate type, required heat transfer temperature, and aftercare instructions. Perform a final product check for alignment, color consistency across batches, and adhesion. Run a small sample from each batch to validate before full shipment; record anomalies to prevent recurrence. |

| Materials, equipment, and setup | Reliable equipment is essential: a quality DTF printer, curing equipment, and a dependable heat press. Choose transfer film, calibrated powders, and compatible fabrics. Regular calibration and documentation of printer profiles, ink batches, and powder lots help trace issues and maintain a stable process. |

| Best practices and troubleshooting | Design within color gamuts, avoid excessive color layering, and use vector elements when possible. Use proofs (soft and hard) to catch color shifts early and share color profiles across teams. When issues arise, map the process, assign ownership, and use a checklist to verify steps. If misregistration, color fade, uneven powder, adhesion problems, or scorching occur, identify the fault area and implement corrective actions in the next run. |