DTF vs DTG sets up a crucial decision for brands aiming for bold graphics on a wide range of fabrics. When you compare DTF printing to other approaches, you can better judge color, durability, and cost per unit over time. This guide explains how each method works, from the film-based transfer process to direct-on-fabric application, so you can align your choice with your fabrics and production goals. Whether you’re printing on cotton, blends, or polyester, the method you choose will influence outcomes like reliability and the overall feel of the print. Exploring setup requirements, turnaround, and maintenance helps you forecast margins and scale with confidence.

Beyond the shorthand, many practitioners frame this decision as a choice between film-based transfers and direct-to-fabric printing. The former uses a coated sheet that carries the artwork, bonds to fabric with heat and pressure, while the latter applies color directly into the fibers through specialized inks and curing steps, offering different hand feels and wash behavior. Each path offers different strengths in color depth, durability, and the feel of the finished product, so testing across your typical fabrics is essential. A careful comparison framed with these terms helps you forecast performance, turn-time, and cost for your catalog or brand. As you plan, consider how your designs translate to multiple materials, because the right term framework makes it easier to discuss requirements with suppliers and printers. Ultimately, you may find a hybrid approach—using film-based transfers for polyester-rich lines and direct-to-fabric printing for cotton-heavy ranges—offers the best mix of speed, durability, and feel.

DTF vs DTG: A Practical Overview of Textile Printing Methods

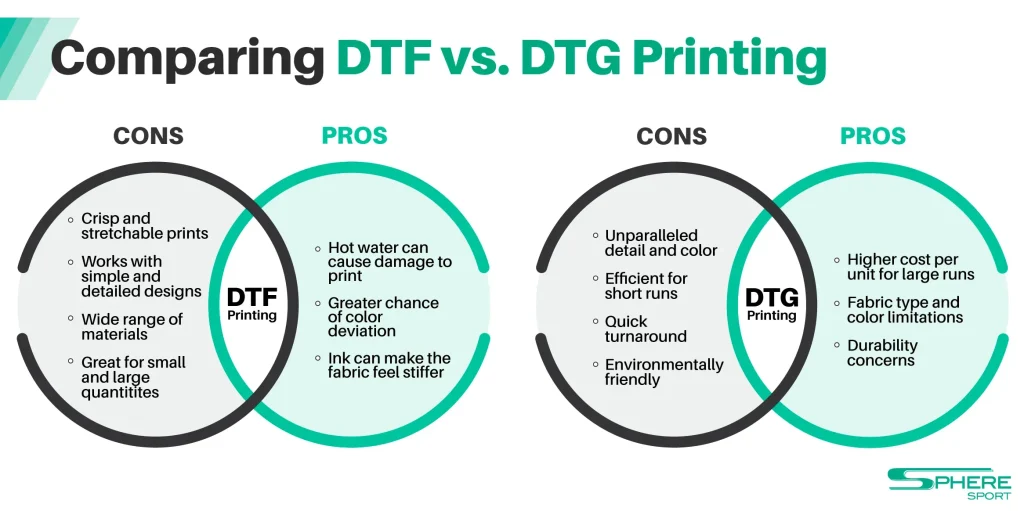

DTF printing and DTG printing represent two of the most widely used textile printing methods today. DTF printing relies on transferring designs from a film with an adhesive powder, enabling vibrant color output across a broad range of fabrics. DTG printing, by contrast, applies water-based inks directly onto the fabric, delivering a soft hand and high-resolution results, especially on cotton-rich textiles.

Understanding these methods lays the groundwork for selecting the right approach for your brand or project. When evaluating DTF printing versus DTG printing, consider fabric type, artwork complexity, and production goals. This overview highlights how each technique aligns with different material ecosystems and business needs, helping you navigate color vibrancy, durability, and cost considerations across textile printing methods.

Color Accuracy in Textile Printing: How DTF and DTG Compare

Color accuracy in textile printing is a major decision driver for many brands. DTF printing typically yields bold, opaque colors on dark textiles due to its transfer film and adhesive system, which helps maintain vibrancy across a variety of fabric types. DTG printing can also deliver rich color, especially on light garments, but achieving consistent brightness on darker shirts often hinges on pretreatment quality and ink management.

Both methods support detailed artwork and smooth gradients, yet the final result depends on curing, film quality, and fabric characteristics. When evaluating color accuracy in textile printing, consider how underbase (for DTG) and film-based color blocks (for DTF) interact with your chosen fabrics. For many applications, DTF provides uniform color fidelity across poly blends and cotton-rich textiles, while DTG shines on high-cotton fabrics with careful prep.

Durability and Wash Fastness: Which Method Stands Up to Repeated Laundering

Durability is a key factor for apparel buyers, and both DTF printing and DTG printing can deliver long-lasting results with proper execution. DTF transfers tend to show strong wash-fastness across diverse fabrics when cured correctly and adhered with a reliable adhesive, making them robust for mid-volume runs across multiple material types.

DTG prints can also be highly durable on suitable fabrics, particularly 100% cotton, provided pretreatment and cure parameters are optimized. However, on some blends or darker fabrics, improper pretreatment can lead to cracking, flaking, or color fading over repeated washes. Overall, DTF often offers broader durability across fabrics, while DTG can deliver a premium hand and color depth on cotton when procedures are meticulously controlled.

Fabric Compatibility and Artwork: Matching DTF and DTG to Your Materials

Choosing the right method depends heavily on fabric type and the intricacies of your artwork. DTF printing provides broad fabric compatibility, including cotton, polyester, and blends, with reliable adhesion and consistent color results. DTG excels on 100% cotton or high-cotton blends, especially for high-detail images and soft hand-feel, when pretreatment and ink saturation are properly managed.

Artwork complexity also guides method selection. Detailed logos, gradients, and photographic-style artwork can be reproduced well by both techniques, but the way color blocks render and how edges maintain sharpness may vary by fabric and process. For catalogs with a wide fabric mix, DTF’s flexibility can simplify production, while DTG remains ideal for cotton-focused lines seeking a premium hand.

Cost, Speed, and Production Workflow: When to Use DTF vs DTG

Production economics play a pivotal role in choosing between DTF printing and DTG printing. DTG printers typically involve higher upfront investment, including pretreatment stations and ongoing maintenance, whereas DTF setups can be more cost-efficient to scale across multiple fabric types due to the modular nature of films, powders, and adhesives.

Per-unit costs and production speed also influence decision-making. DTF often offers lower costs for mid-sized runs with a wide design variety, while DTG can be cost-effective for small, high-value orders on cotton when pretreatment expenses are managed. In high-volume contexts, production workflows and automation can shift the advantage toward one method depending on fabric mix and output goals.

Quality Assurance and Testing: Validating DTF and DTG Results Before Scaling

A proactive testing program helps ensure consistent results across fabrics and designs. Begin with a set of samples printed on each fabric you intend to use, then evaluate color accuracy in various lighting conditions and test multiple wash cycles to gauge durability. This iterative approach aligns with best practices in textile printing methods and helps identify curing times, pressure settings, and pretreatment needs.

Quality assurance should also assess edge integrity, crack resistance, and overall feel across garments. By building a robust test plan, you can validate the performance of both DTF printing and DTG printing, ensuring customer satisfaction and minimizing returns. This evidence-based approach supports smarter decisions about which method to scale for different product lines and fabric groups.

Frequently Asked Questions

DTF vs DTG: What’s the key difference and when should you use each method?

DTF printing uses a film transfer with adhesive, offering broad fabric compatibility (including polyester) and strong color on dark textiles. DTG printing applies water‑based inks directly to natural fibers, delivering a soft hand and high detail on light garments. Choose DTF for versatility and mid‑volume runs; choose DTG for premium hand feel on cotton with detailed images.

How does color accuracy in textile printing compare between DTF printing and DTG printing?

Color accuracy in textile printing depends on fabric and workflow. DTF printing often delivers consistent color across many fabrics thanks to the transfer film, including dark textiles. DTG can achieve vivid colors on light cotton when pretreatment and ink management are well controlled, though dark fabrics may require extra underbase planning. Run fabric-specific tests to confirm color fidelity.

Which offers better print durability for apparel across fabrics: DTF printing or DTG printing?

Both can be durable with proper curing. DTF generally maintains adhesion and color across a wide range of fabrics (cotton, polyester, blends). DTG tends to be very durable on 100% cotton when pretreatment and cure are optimized, but performance on blends or dark fabrics can vary. Plan wash testing on representative materials.

Among textile printing methods, which fabrics and scenarios favor DTF printing over DTG printing?

DTF printing excels for mixed fabrics and broad compatibility, including polyester and blends, with faster setup for many colors. It performs well on dark garments and diverse SKUs. DTG is best on 100% cotton with high detail and a premium hand on light garments. For mixed fabrics or frequent changes, DTF is often preferred; for cotton‑centric lines, DTG delivers a superior hand feel.

What are the cost, production speed, and labor considerations when choosing DTF vs DTG for textile printing methods?

DTF often offers lower per‑unit costs for mid‑volume runs across many fabrics and simpler setup. DTG usually requires higher upfront investment (printer, pretreatment) but can deliver fast throughput on cotton designs when managed well. Production speed depends on batch size and design complexity; ongoing maintenance and consumables differ between the two methods.

How can I test color accuracy in textile printing and wash durability when deciding between DTF printing and DTG printing?

Print a small test batch on representative fabrics. Compare color accuracy under standard lighting, then run several wash cycles per your care guidelines to assess durability. Use consistent curing and pretreatment (where applicable), and check edge quality and color stability before scaling.

| Topic | DTF Highlights | DTG Highlights | Best Use | Fabric Notes |

|---|---|---|---|---|

| How It Works | Film-based transfer printed with adhesive powder; cured; heat-pressed to fabric. | Direct-to-fabric printing with water-based inks; ink soaks into fibers; cured/heat-set. | DTF: versatile across fabrics; DTG: cotton-centric workflows. | DTF: cotton, polyester, and blends; DTG: best on 100% cotton or high-cotton blends |

| Color & Gradients | Bold, vivid colors; opaque whites on dark textiles; strong color output across fabrics. | Rich colors on light fabrics; pretreatment may be needed for dark garments; smooth gradients. | DTF: broad fabric range; DTG: premium hand on cotton. | DTF: performs well on poly blends; DTG: optimized on cotton |

| Durability | High wash-fastness when properly cured; adheres well across fabrics. | Durable on suitable fabrics; potential issues on blends without pretreatment. | DTF: durable across fabrics; DTG: durable on cotton with correct pretreatment. | DTF: adhesive film may feel plasticky; DTG hand is soft |

| Cost & Production | Lower per-unit for mid-sized runs; scalable; simpler maintenance. | Higher upfront investment; higher per-unit for small runs; pretreatment costs. | DTF: mixed-fabric portfolios; DTG: cotton-focused, low-to-mid volume runs. | DTF: films, powders, adhesives; DTG: inks, pretreatment chemicals |

| Care & Longevity | Proper curing; follow care labels; avoid aggressive high-heat washing. | Follow care labels; avoid high heat; pretreatment impacts longevity. | Both require proper care for longevity. | Turn garment inside-out; wash cold; avoid bleach; air dry when possible |

| Choosing Right Approach | DTF: broad fabric compatibility; mid-volume efficiency. | DTG: premium hand on cotton; high-detail on light garments. | Consider a hybrid approach: DTF for poly/broad fabrics; DTG for cotton lines. | Test prints across fabrics and designs; optimize curing and pretreatment. |

Summary

DTF vs DTG is a thoughtful, data-driven choice for brands and creators. When choosing between DTF and DTG, consider your target fabrics, artwork complexity, order volume, and desired hand feel. DTF offers broad fabric compatibility and strong color performance across a wide range of textiles, making it well-suited for mid-volume production and diverse catalogs. DTG delivers premium softness and high-detail results on 100% cotton and light fabrics with careful pretreatment, ideal for cotton-centric lines. Many brands benefit from a blended approach—DTF for poly blends and mixed fabrics, and DTG for cotton-heavy runs. Start with small test batches to compare color fidelity, durability, and hand feel, and optimize curing and pretreatment to maximize outcomes for both methods.