Advanced DTF Gangsheet Builder Techniques are at the forefront of transforming the printing industry by enhancing efficiency and quality. As businesses strive to differentiate themselves in a competitive landscape, these innovative approaches to Direct-to-Film (DTF) printing provide substantial advantages. By optimizing gangsheet printing methods, companies can streamline their workflows, reduce operational costs, and significantly improve the graphic reproduction quality of their outputs. In this context, leveraging advanced DTF printing techniques not only enhances the overall printing process but also supports the ever-evolving demands of the market. Join us as we explore the latest advancements that are revolutionizing how we approach DTF printing and gangsheet production.

In the realm of digital textile printing, advanced strategies for gangsheet creation and optimization are reshaping the game. These techniques emphasize the use of Direct-to-Film (DTF) methodologies, which allow for intricate designs to be printed efficiently on various substrates. With a focus on enhancing the printing process through sophisticated software tools and improved ink formulations, businesses can now ensure vibrant and durable prints that meet high-quality standards. By adopting these modern practices, companies can not only streamline their production but also align with best practices in graphic reproduction. This exploration will reveal how these innovative approaches can elevate your printing operation to new heights.

Understanding DTF Printing Essentials

Direct-to-Film (DTF) printing has emerged as a pivotal technology in the graphic reproduction landscape, allowing for the transfer of intricate designs onto a multitude of surfaces. At its core, DTF utilizes specialized inks that are printed onto a film before heat pressing onto the substrate. This process ensures high-definition prints with vibrant colors and detailed designs, making it an ideal choice for garments, accessories, and promotional items. Moreover, by focusing on this innovative approach, businesses can significantly enhance their production capabilities while reducing material waste.

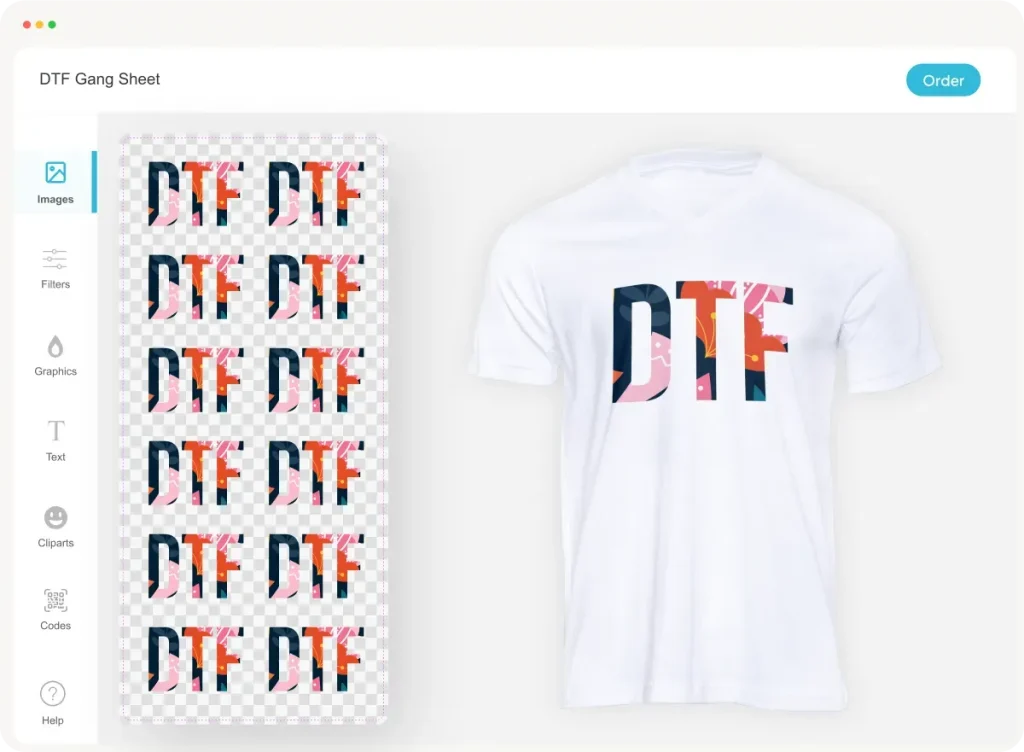

In essence, DTF printing bridges the gap between traditional screen printing and digital printing, offering the best of both worlds. The flexibility of using gangsheet printing techniques further amplifies its benefits, allowing multiple designs to be printed in a single batch. This not only optimizes resources but also cuts down production time, enabling businesses to cater to larger orders more efficiently while maintaining high-quality standards. Such features make DTF printing a game-changer for both small and large-scale printing operations.

The Advantages of Gangsheet Printing

Gangsheet printing optimizes the entire printing process by enabling multiple designs to be printed simultaneously on a single sheet. This method greatly enhances material utilization, reducing costs associated with wastage and increasing profitability for printing businesses. By consolidating multiple designs on one output, businesses can cater to more clients in less time, ensuring that they remain competitive in a fast-paced market environment.

Additionally, the gangsheet technique streamlines workflow by minimizing the number of print runs needed, leading to fewer setups and operational disruptions. As a result, companies can enjoy improved turnaround times, making it easier to handle urgent orders without sacrificing quality. The dual benefits of cost efficiency and speed make gangsheet printing an essential strategy for businesses looking to thrive in the ever-evolving printing industry.

The Role of Software in DTF Printing

Software optimization plays a crucial role in enhancing DTF gangsheet printing efficiency. Modern software tools are designed to simplify the input and arrangement of designs, making it easy for users to create complex layouts that maximize the use of available space. These innovations reduce the time needed for file preparation and ensure that prints are produced with precision, thereby elevating the overall production quality.

Furthermore, many DTF printing software solutions are equipped with features that allow for batch processing. This capability enables businesses to prepare multiple jobs simultaneously, minimizing downtime and accelerating the production schedule. By incorporating advanced software into their processes, printing companies can significantly improve their productivity and meet increasing customer demands without compromising on print quality.

Innovations in DTF Ink Formulations

Innovations in DTF ink formulations have transformed the quality of prints produced through this method. Enhanced ink properties not only improve color vibrancy but also increase adhesion and durability on various substrates. This means that prints created with advanced DTF inks are not only visually striking but are also resistant to fading, peeling, or cracking, especially after multiple washes.

Moreover, these sophisticated ink formulations reduce issues such as sink-in, where the ink gets absorbed into the material, which can lead to dulling of colors. By minimizing such problems, manufacturers and printers can ensure a consistent output quality, thereby enhancing customer satisfaction and building a loyal client base. As DTF printing technology continues to evolve, focusing on ink formulations will be key to staying competitive in the industry.

Automating the DTF Printing Process

The advent of automation in the DTF printing process has revolutionized operational efficiency. By implementing automated systems for cutting, weeding, and heat pressing, businesses can significantly reduce manual handling, which often leads to errors and inefficiencies. Automation allows for faster processing times, enabling companies to fulfill larger orders and make quicker deliveries without compromising on the quality of prints.

Additionally, automation technology can integrate with existing DTF printing machines, enhancing the overall production workflow. This synergy not only streamlines operations but also opens the door for scaling up operations without a proportional increase in labor costs. As automation continues to advance, companies that embrace these technologies will find themselves better positioned to meet the demands of a rapidly evolving market.

Investing in Education and Resources for DTF Techniques

Investing in education and resources is critical for businesses aiming to leverage advanced DTF gangsheet builder techniques effectively. Reliable industry partners and educational platforms offer a wealth of resources, from tutorials to case studies, which can significantly bolster knowledge of DTF printing processes. By staying informed about the latest advancements and best practices, businesses can maximize their operational efficiency and product offerings.

Further, engaging with industry forums and communities provides valuable networking opportunities, where businesses can share insights, challenges, and solutions with peers. Learning from the experiences of others, especially those who have successfully transitioned to advanced DTF techniques, can provide practical guidance and inspire innovation. By prioritizing continuous learning, companies can remain competitive and responsive to the evolving demands of the printing industry.

Frequently Asked Questions

What are advanced DTF gangsheet builder techniques and why are they important for DTF printing?

Advanced DTF gangsheet builder techniques refer to the modern methods and software optimizations used in the Direct-to-Film (DTF) printing process. These techniques are crucial because they enhance printing efficiency, improve graphic reproduction quality, and reduce material waste, ultimately leading to cost savings for businesses in the printing industry.

How do software optimizations enhance the DTF printing process?

Software optimizations in DTF printing streamline design input, layout management, and printing settings adjustments. By automating these processes, advanced DTF gangsheet builder techniques reduce time spent on file preparations and allow batch processing, which results in faster and more efficient production.

What benefits do improved ink formulations provide in advanced DTF gangsheet printing?

Improved ink formulations in DTF printing offer greater vibrancy, adhesion, and durability of prints. These advanced inks minimize sink-in effects, ensuring that graphics produced maintain their quality through multiple washes, which ultimately leads to higher customer satisfaction and repeat business.

How does automation in DTF gangsheet production influence operational efficiency?

Automation in DTF gangsheet production, such as automated cutting and weeding, significantly boosts operational efficiency by saving time and reducing manual handling. This leads to faster output and increased accuracy, allowing businesses to handle larger orders without compromising quality.

In what ways can businesses achieve cost reduction through advanced DTF gangsheet builder techniques?

Businesses can achieve cost reductions by maximizing material utilization through gangsheet printing, which allows for multiple designs to be printed on a single sheet. This optimization of materials reduces waste and lowers overall production costs, allowing savings to be redirected into other operational areas.

What resources are available for learning about advanced DTF gangsheet techniques?

Various resources are available to learn about advanced DTF gangsheet techniques, including industry publications like Print Business Magazine and Impressions Magazine, and blogs from companies like Roland DGA. These platforms provide updated articles, case studies, and tutorials to help businesses optimize their DTF printing processes.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A modern printing technique that transfers high-quality graphics onto various substrates using special inks printed on a film. |

| Advancements in DTF Gangsheet Techniques | Includes software optimization, improved ink formulations, automation, and built-in quality control measures to enhance printing efficiency. |

| Benefits of Upgraded Techniques | Cost reduction through material utilization, enhanced print quality, and operational efficiency leading to faster production without compromising standards. |

| Implementation in Business | Case studies showing reductions in material waste and increases in production speed, highlighting the advantages of DTF printing in competitive operations. |

| Resources for Learning and Growth | Educational materials and industry insights from Print Business Magazine, Roland DGA Blog, Impressions Magazine, and Screen Printing Magazine. |

Summary

Advanced DTF Gangsheet Builder Techniques are transforming the way businesses operate within the printing industry. This innovative approach not only enhances the quality and efficiency of printing processes but also significantly reduces operational costs. By embracing these advanced techniques, businesses can streamline their production, ensuring they remain competitive in a rapidly evolving market. The future of DTF printing looks promising; those who invest time and resources into mastering these techniques will undoubtedly find themselves at the forefront of the printing landscape, ready to meet the demands of their customers with superior products.