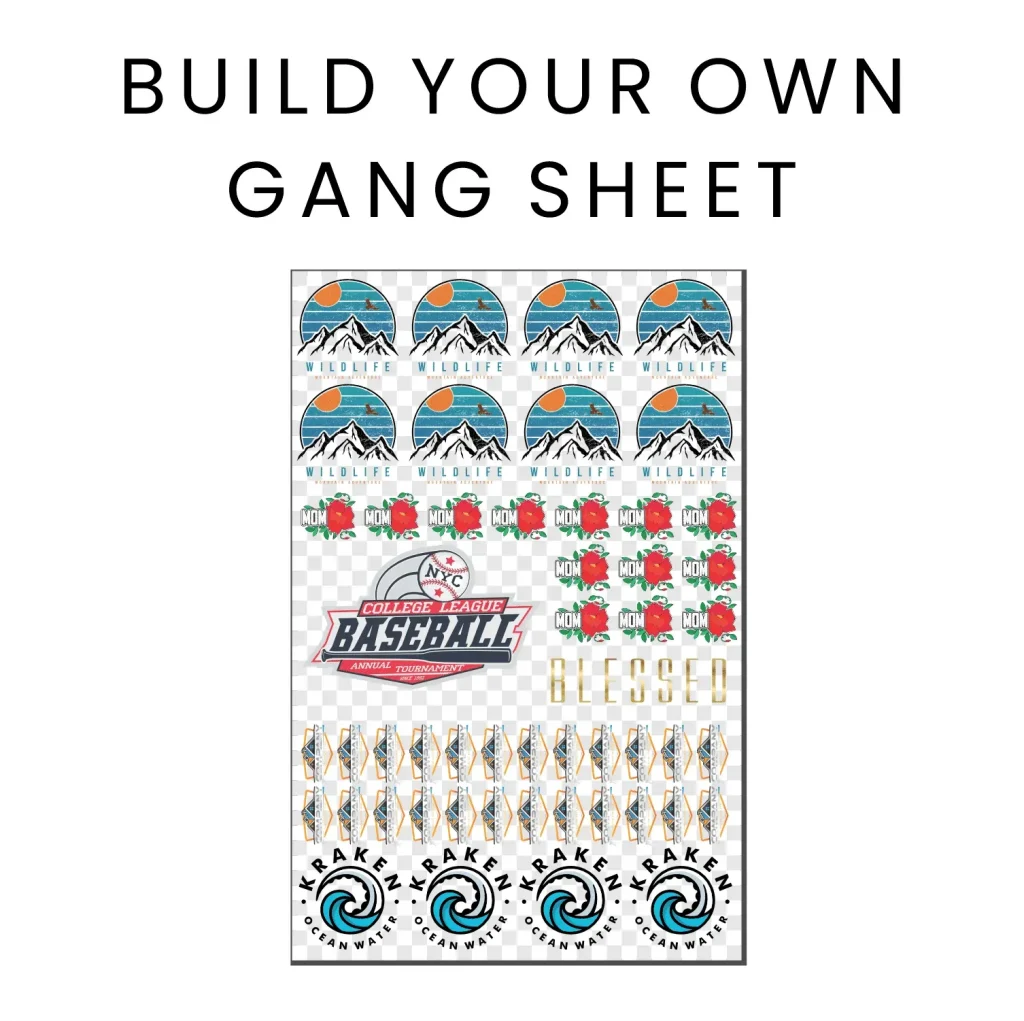

The DTF Gangsheet Builder is revolutionizing the world of apparel design by streamlining the gangsheet printing process with ease and creativity. This innovative software allows users to print multiple intricate designs on a single sheet, ideal for efficient DTF printing and heat transfer applications. With its ability to enhance color vibrancy and detail retention, designers can effectively utilize various shirt printing techniques, yielding high-quality results suitable for any fabric. As the popularity of DTF design software grows, so does the potential for creating unique garments tailored to individual tastes and styles. In this guide, we will delve into the DTF gangsheet printing method, exploring its advantages and the step-by-step process for achieving stunning designs.

Direct-to-Film (DTF) gangsheet printing has emerged as a game-changing printing technique, blending creativity with cutting-edge technology in the textile industry. This method processes several designs simultaneously, optimizing material usage and reducing costs, which is highly beneficial for businesses and DIY enthusiasts alike. As we explore the realm of heat transfer printing, you will discover how this versatile approach accommodates various shirt printing techniques, ensuring captivating and durable designs. By harnessing the capabilities of specialized DTF design software, printing professionals can unlock a world of possibilities in creating custom apparel. Join us as we uncover the essentials of utilizing a DTF gangsheet builder for remarkable design outputs that captivate and inspire.

Exploring the Basics of DTF Printing

DTF printing, or Direct-to-Film printing, provides an innovative method for applying vibrant designs directly onto textiles. This process stands out by allowing detailed graphics to be printed onto a special film instead of directly onto fabric. Once printed, the films are coated with adhesive and heat-pressed onto the fabric, resulting in striking visual effects that rival traditional printing methods. Notably, DTF printing preserves color vibrancy and intricacy, making it a preferred choice among textile designers.

The fundamental advantage of DTF printing lies in its versatility. This technique accommodates a wide range of fabrics, from cotton and polyester to blends, thus catering to various printing needs. Additionally, it minimizes waste through efficient use of materials, aligning with eco-conscious production practices. When using a DTF gangsheet builder, multiple designs can be printed per sheet, which significantly optimizes resources and reduces costs, proving beneficial for both small businesses and larger operations.

The Benefits of a DTF Gangsheet Builder

Utilizing a DTF gangsheet builder offers substantial economic benefits, primarily through cost-efficiency. By grouping multiple designs onto a single gangsheet, print businesses can lower their ink and film expenditure. This strategic approach helps maintain budget constraints while maximizing output. Furthermore, the ability to print several designs at once accelerates production timelines, allowing businesses to meet tight deadlines without compromising quality.

In addition to financial advantages, a DTF gangsheet builder streamlines the entire printing workflow. The software facilitates the organization of designs, enabling users to quickly position graphics for optimal layout before the printing process begins. This organized approach results in more polished final products and enhances productivity by eliminating redundant steps typical of conventional printing methods.

Step-by-Step Guide: Creating Designs Using DTF Design Software

Creating designs using DTF design software involves a systematic approach that begins with planning and preparation. Before diving into the digital realm, it’s crucial to gather your design materials and decide on your concepts. High-quality graphics can be created or edited in industry-standard software like Adobe Illustrator, ensuring designs are print-ready and optimized for clarity. The choice of colors and layering will be fundamental in achieving the desired outcomes, as these factors significantly affect the final print quality.

Once designs are finalized, transferring these assets to a DTF-specific design program is the next step. Tools like Seps4 and CADlink can automate color separation and prepare the designs for gangsheet integration. By adjusting the layout to fit multiple graphics onto a single sheet, users can preview configurations, making further modifications as necessary. This preparation is crucial to ensuring that every detail is captured and flawlessly printed during the DTF process.

Understanding the Printing Process in DTF Techniques

The printing process is a pivotal stage in DTF techniques, requiring meticulous attention to detail to achieve high-quality results. Initially, the specially coated DTF film needs to be properly loaded into the printer, ensuring compatibility with the type of printer being used. Utilizing high-quality inks is equally important, as the choice of inks influences the adhesion of the design once it’s transferred to the fabric. Adjusting these settings based on fabric type is critical for maintaining color fidelity and overall design integrity.

After successful printing, the application of adhesive powder plays an essential role in achieving a robust bond between the film and the textile. This step requires precision, as an even layer of adhesive is vital for uniform coverage. Using a heat press at the appropriate temperature and pressure settings ensures that the design adheres effectively, thereby enhancing durability. This critical process ultimately defines the quality and longevity of the final product.

Tips for Successful Heat Transfer in DTF Printing

Executing a successful heat transfer is an art that requires careful monitoring of several factors. It’s essential to allow printed designs to cool adequately before transferring them onto the fabric. This cooling period is crucial for ensuring that the ink sets correctly, which in turn affects how the design adheres during heat application. Proper timing, pressure, and temperature settings based on the specific fabric used are vital; otherwise, there may be issues such as peeling or fading.

For best practices, always refer to the manufacturer’s guidelines regarding recommended heat settings for each fabric type to maximize the effectiveness of the application. Using a quality heat press further enhances the transfer process, offering consistent results across varied designs. Additionally, inspecting the transfer thoroughly post-application will ensure any imperfections can be addressed before finalizing your products, helping to maintain high standards of quality.

Resources for Mastering DTF Gangsheet Printing Techniques

For those eager to expand their knowledge of DTF gangsheet printing, numerous resources are at your disposal. Online tutorials from industry leaders can provide insights into various aspects of the process—from initial design to the final application. Platforms like YouTube host numerous video demonstrations that can visually guide users through complex steps, offering a more interactive learning experience.

Moreover, joining community forums and online groups can also be immensely beneficial. Engaging with experienced DTF printers allows you to ask questions, share experiences, and learn innovative techniques that may not be covered in official resources. Networking within these communities can enrich your understanding and enhance your skill set, paving the way for greater success in the realm of DTF printing.

Frequently Asked Questions

What is DTF Gangsheet Builder and how does it work?

A DTF Gangsheet Builder is a specialized software tool used in gangsheet printing, allowing users to combine multiple designs into one transfer film for efficient shirt printing. The builder helps in aligning and optimizing designs to ensure high-quality outputs through the DTF printing process.

What are the benefits of using DTF gangsheet printing?

DTF gangsheet printing offers several advantages, including cost efficiency by minimizing ink usage, time savings by processing multiple designs at once, and high-quality outputs that maintain vibrant colors and details on various fabrics.

How can I create designs using DTF gangsheet builder software?

To create designs with a DTF gangsheet builder, prepare your artwork using graphic design tools, upload the designs to the software, adjust the layout for optimal film use, and ensure proper alignment before printing.

What materials do I need for the DTF printing process?

For DTF printing, you’ll need DTF film, high-quality inks, adhesive powder, and a heat press. These materials are crucial for achieving successful heat transfer printing and adhering designs to fabrics.

Can I use DTF printing for various fabric types?

Yes, DTF printing is versatile and can be applied to a variety of fabric types, including cotton, polyester, and blends, making it an ideal choice for shirt printing techniques that require durability and vibrancy.

Where can I find resources to learn more about DTF design software?

To learn more about DTF design software and gangsheet printing, you can explore online tutorials on platforms like Printavo, participate in community forums, and watch instructional videos on YouTube to enhance your skills.

| Key Points | Details |

|---|---|

| What is DTF Gangsheet Printing? | A printing technique that allows multiple designs to be printed seamlessly onto one transfer film, preserving color and detail. |

| Advantages of Using a DTF Gangsheet Builder | Cost efficiency, time-saving benefits, and high-quality output are the main advantages. |

| Steps in Creating Designs | 1. Design Preparation 2. Using a DTF Software Tool 3. Printing Process 4. Heat Transfer 5. Final Touches |

| Resources for Further Learning | Online tutorials and community support groups focused on DTF printing. |

Summary

The DTF Gangsheet Builder revolutionizes the textile design process by streamlining the creation of intricate designs on a single sheet, reducing costs and production time. This innovative technique showcases vibrant, high-quality outputs ideal for any fabric application. By mastering the steps of preparation, printing, and heat transfer, designers can efficiently produce stunning final products that stand out in the market. As the popularity of DTF printing expands, embracing this method through a DTF Gangsheet Builder will enhance your creative projects, offering new possibilities for artistic expression.