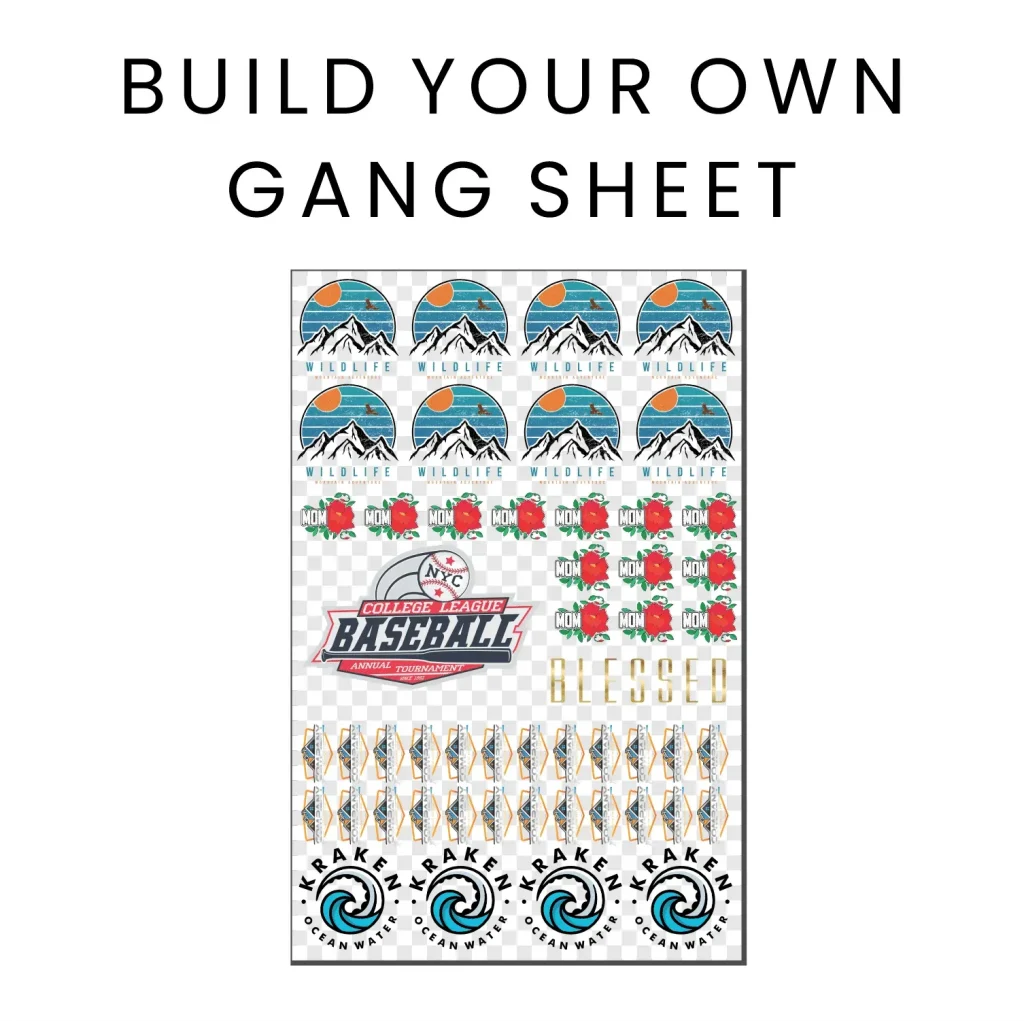

The DTF Gangsheet Builder is a game-changing tool for graphic designers, small business owners, and print shop operators aiming to enhance print efficiency. This innovative software leverages the power of Direct to Film (DTF) printing, which has surged in popularity due to its capacity to deliver stunning, high-resolution prints. By utilizing gang sheets, users can print multiple designs simultaneously on a single sheet, maximizing material usage and time efficiency. In this guide, we’ll dive into the intricacies of DTF printing and provide tips on optimizing your designs with the DTF Gangsheet Builder. Get ready to streamline your printing process and elevate your design projects!

If you’ve been searching for a way to boost your printing workflow, the DTF Gangsheet Builder offers an unparalleled solution for arranging your designs. This software simplifies the process of preparing gang sheets, allowing for efficient printing that combines multiple images into one cohesive layout. As businesses increasingly turn to Direct to Film technology for its superior print quality and versatility, mastering tools like the gangsheet builder becomes essential. Embrace design optimization strategies that help you save resources while achieving vibrant results. Jump into this guide to uncover the best practices for leveraging the gangsheet printing technique to its fullest potential.

The Benefits of DTF Printing for Small Businesses

DTF printing offers a myriad of benefits for small businesses looking to enter the custom apparel or product market. One of the standout advantages is its ability to produce vibrant, high-quality prints that can withstand repeated washing, making it ideal for garments. This print method is not only versatile across various fabrics but also allows for intricate designs that resonate with consumers. With DTF printing, business owners can cater to niche markets by offering customized designs without the high costs associated with traditional screen printing.

Moreover, DTF printing is renowned for its efficiency, particularly when employing techniques like the DTF Gangsheet Builder. By utilizing gang sheets, small business owners can print multiple designs in one go, minimizing material waste and reducing production time significantly. This means quicker turnaround times for orders, enabling businesses to respond to market demands with agility. In a competitive landscape, the combination of superior print quality and operational efficiency gives small businesses a crucial edge.

How the DTF Gangsheet Builder Enhances Print Efficiency

The DTF Gangsheet Builder is a powerful tool designed to enhance print efficiency within the DTF printing process. By allowing users to arrange various designs on a single sheet, this tool not only maximizes space but also minimizes ink and material waste. The builder’s features enable designers to easily import designs, adjust sizes, and arrange them meticulously, ensuring every inch of the gang sheet is utilized effectively. This optimization is pivotal in achieving high output while maintaining quality.

Additionally, the DTF Gangsheet Builder simplifies the workflow for print operators. With intuitive features such as grid alignment and instant preview, users can spot limitations in their layout before printing, which significantly reduces the likelihood of errors such as misalignment or ink smudging. These capabilities streamline the preparation process, allowing print shops to handle larger volumes of work without compromising on quality or detail.

Maximizing Material Use with Gang Sheets

One of the primary advantages of gang sheets in DTF printing is their ability to maximize material use. By consolidating multiple designs onto a single sheet, businesses can significantly reduce fabric waste and printing costs. This efficiency is crucial, especially for smaller print runs or custom orders where every bit of material counts. The DTF Gangsheet Builder allows users to strategically plan their layouts, ensuring that designs are not just packed onto the sheet but arranged in a manner that adheres to both aesthetic and functional printing considerations.

Furthermore, optimizing the arrangement of designs can lead to better overall print yields. When using the DTF Gangsheet Builder, designers can experiment with design placement and spacing to ensure that the maximum number of prints can be made from a single piece of transfer film. This not only enhances profitability by lowering production costs but also supports sustainable practices by reducing waste in the printing process.

Tips for Effective Design Optimization in DTF Printing

Design optimization is critical to achieving the best results in DTF printing, and employing the DTF Gangsheet Builder enhances this process. A key tip for effective optimization is to focus on uniformity across designs. Keeping sizes, fonts, and color schemes consistent contributes to a professional look and minimizes setup errors. As users work with gang sheets, it’s essential to factor in the space each design occupies, ensuring they are appropriately spaced to allow for precision cutting without sacrificing quality.

Additionally, designers should test prints before finalizing their gang sheets. Running trial prints can reveal potential issues with color fidelity and design alignment, which are critical to preventing costly mistakes. The DTF Gangsheet Builder can aid in pre-emptive adjustments by allowing users to visualize the final output before committing to a print run. This attention to detail not only helps improve the final product but also saves time and resources in the long run.

Troubleshooting Common Issues in DTF Printing

Despite the advantages of DTF printing, users may encounter common issues throughout the printing process. One frequent problem is ink smudging, which can detract from the final product’s quality. To troubleshoot this, it’s vital to ensure that prints are properly cured and that ink levels are consistently monitored. Understanding the curing process, including temperature and time settings, can help mitigate the risk of smudged prints, ensuring that designs come out sharp and clean.

Misalignment of designs is another common issue that may arise when using the DTF Gangsheet Builder. To address this, users should pay careful attention to their layout before printing. Utilizing the alignment tools within the builder can help position designs accurately, which is crucial for a successful transfer. By double-checking every aspect of the design layout, including the spacing between elements, users can dramatically reduce the chances of errors and enhance the quality of their finished prints.

The Future of DTF Printing and Gang Sheets

The future of DTF printing and the utilization of gang sheets looks bright as the technology continues to evolve. As demand for custom printing grows, the efficiency and quality provided by DTF methods are likely to solidify its place in the textile industry. Innovations in ink formulations and transfer technology are expected to enhance durability and color vibrancy further. The DTF Gangsheet Builder will continue to play a pivotal role in this transition, enabling more designers to explore complex designs while managing production costs effectively.

Additionally, as more businesses and individuals adopt sustainability practices, the DTF printing process aligns perfectly with these values by reducing waste through the effective use of gang sheets. The ability to print high-quality designs on demand will cater to consumer preferences for personalized products without the environmental toll of traditional printing methods. Overall, the marriage of innovative design tools like the DTF Gangsheet Builder with forward-thinking printing practices promises a dynamic future for graphic designers and print shops alike.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized software tool designed for optimizing the layout of designs in Direct to Film (DTF) printing. It enables users to efficiently arrange multiple graphics on a single gang sheet, maximizing print efficiency and reducing material waste. Using this builder, you can easily drag, drop, and align your designs before exporting them for printing.

How can I improve print efficiency with the DTF Gangsheet Builder?

To improve print efficiency using the DTF Gangsheet Builder, focus on maximizing the space on your gang sheet by strategically placing designs without overcrowding. Additionally, ensure that your designs are properly aligned and evenly spaced to facilitate effective cutting and transfer, which in turn leads to faster production times and reduced waste.

What are the advantages of using gang sheets in DTF printing?

Using gang sheets in DTF printing allows multiple designs to be printed simultaneously on one sheet, which enhances efficiency and reduces material waste. This method is particularly beneficial for small orders or custom designs, enabling print shop operators to deliver high-quality products quickly and cost-effectively.

What types of designs can I include in a DTF Gangsheet?

You can include various types of designs in a DTF Gangsheet, such as logos, graphics, text, and illustrations. It’s important to ensure that these designs are in high-resolution formats like PNG or PDF to maintain print quality. Proper arrangement and optimization within the DTF Gangsheet Builder are key to successful printing.

What should I consider when preparing my designs for the DTF Gangsheet Builder?

When preparing your designs for the DTF Gangsheet Builder, consider the resolution of your graphics, as higher quality files yield better prints. Additionally, take into account the size and placement of each design on the gang sheet to maximize space and ensure uniformity, which is essential for a seamless printing process.

What common issues can arise when using the DTF Gangsheet Builder and how can I troubleshoot them?

Common issues when using the DTF Gangsheet Builder include ink smudging, misalignment of designs, and color fading. To troubleshoot these problems, ensure proper ink levels and curing times to prevent smudging, double-check your layout for alignment before printing, and follow manufacturer’s guidelines for curing temperatures to avoid color fading.

| Key Topic | Description |

|---|---|

| DTF Printing | A method of transferring designs onto fabrics using a special film and heat transfer. |

| Gang Sheets | Large sheets containing multiple designs, allowing efficient printing. |

| DTF Gangsheet Builder | A tool for arranging designs on gang sheets to maximize print utilization. |

| Preparation Steps | Gather high-resolution designs, access the builder software, and arrange designs meticulously. |

| Optimization Tips | Maximize space, test prints, ensure material compatibility, and maintain consistency across designs. |

| Troubleshooting | Address issues like ink smudging, misalignment, and color fading by following best practices. |

Summary

The DTF Gangsheet Builder is a vital tool for graphic designers and print shop operators who seek to streamline their DTF printing processes. By mastering the DTF Gangsheet Builder, users can enhance efficiency, minimize waste, and achieve high-quality results in their prints. This comprehensive guide provides the essential knowledge and tips necessary to effectively utilize gang sheets, making it an invaluable resource for anyone looking to optimize their printing workflow.