The DTF Gangsheet Builder is revolutionizing the world of custom apparel printing, offering users a streamlined approach to design creation and workplace efficiency. Leveraging DTF printing technology, this innovative tool enables you to arrange multiple designs on a single film, maximizing material use and boosting productivity. Understanding best practices for DTF, such as choosing high-quality artwork and proper heat press techniques, can elevate your textile printing game. With the DTF Gangsheet Builder, you can explore limitless creative horizons while ensuring vibrant, durable prints. In this article, we will delve into effective strategies for success, helping you unlock your true potential in the realm of custom designs.

Introducing the DTF Gangsheet Builder opens up a world of opportunities for custom graphics enthusiasts and textile creators alike. This tool facilitates Direct to Film printing, enabling users to efficiently manage their design layouts while optimizing the usage of DTF films. It represents a fusion of artistry and technology, allowing creators to produce high-quality prints that resonate with today’s fashion trends. By adopting the best methodologies associated with DTF approaches, users can harness superior printing techniques and create stunning, customized apparel effortlessly. Join us as we dive deeper into the mechanics of this remarkable tool and explore practical methods for mastering DTF processes.

The Evolution of DTF Printing Technology

DTF printing has revolutionized the textile printing landscape, emerging as a versatile and cost-effective solution for custom apparel printing. Unlike traditional methods like screen printing, DTF allows for stunning high-resolution prints on a variety of fabrics, catering to an expanding market of personalized fashion. This transformation is powered by innovations such as the DTF Gangsheet Builder, which streamlines the design process, enabling users to create multiple customized designs on a single sheet efficiently.

As this technology continues to evolve, it remains essential for users to understand the nuances of DTF printing. This includes grasping the specific requirements of the printing equipment, maintaining the quality of artwork, and mastering the thermal transfer techniques. The integration of these elements not only enhances print quality but also improves operational efficiency, positioning DTF technology as a staple in the custom apparel industry.

Maximizing Efficiency with DTF Gangsheet Builder

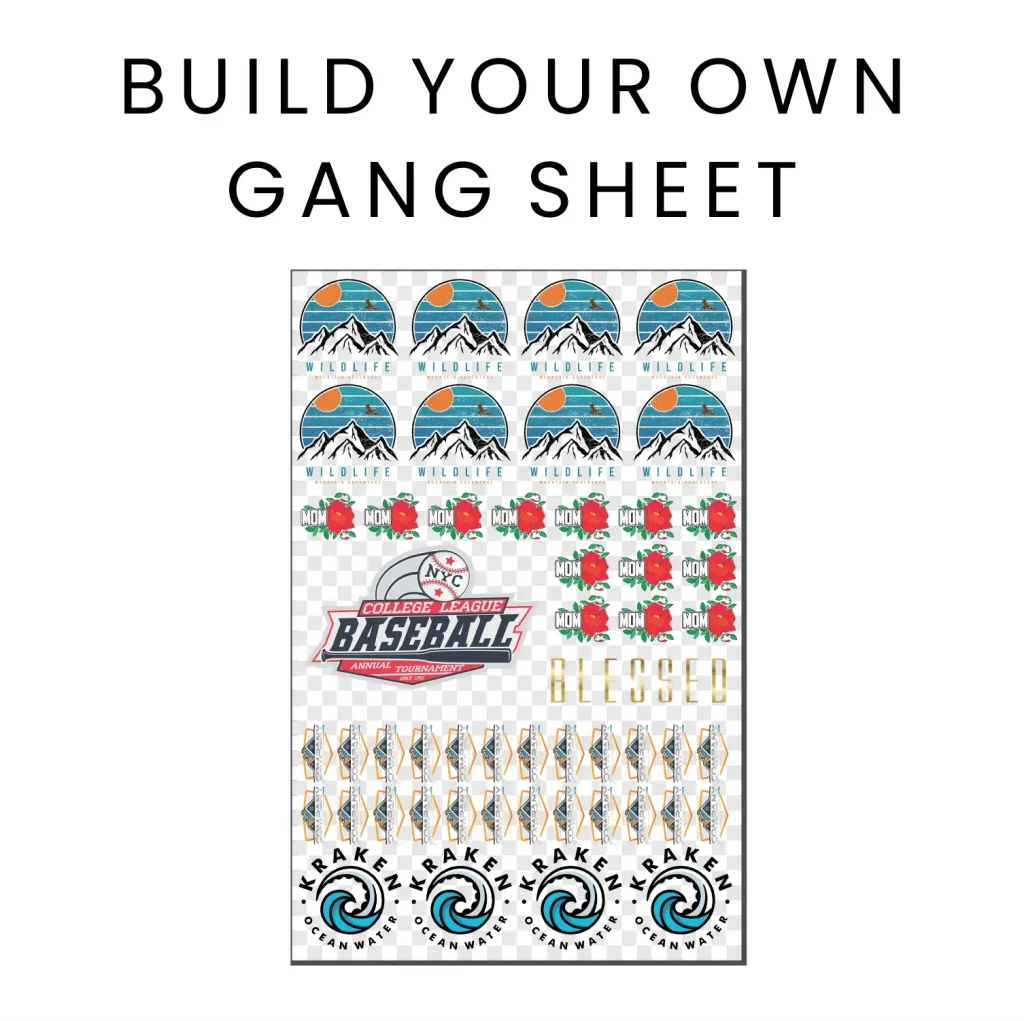

The DTF Gangsheet Builder is instrumental in maximizing workflow efficiency in DTF printing. By allowing users to arrange multiple designs on a single film sheet, this tool effectively reduces material waste and speeds up production time. When utilizing this feature, it is essential to plan your layout carefully, considering the size and arrangement of each design to ensure that they fit perfectly without overlap during the printing process.

Moreover, optimizing the settings within the DTF Gangsheet Builder can significantly impact the final outcome. Adjusting parameters such as ink saturation and resolution helps achieve a vibrant and clear print. Users should regularly experiment with their configurations, refining their settings based on test prints to find the perfect balance that enhances not only visual appeal but also durability.

Best Practices for Artwork Preparation

Preparation of high-quality artwork is crucial for successful DTF printing. Users should prioritize using vector graphics or high-resolution raster images to ensure clarity and prevent pixelation in their prints. Tools like Adobe Illustrator can assist with designing and optimizing images specifically for DTF performance. Adequate file resolution and correct color settings play a fundamental role in achieving print quality that meets or exceeds expectations in custom apparel.

In addition, users must be aware of file formats and color profiles that work best for DTF printing. Taking time to prepare the artwork by employing best practices not only minimizes errors during printing but also enhances the overall quality of the final product. High-resolution designs, coupled with precise adjustments in the Gangsheet Builder, lead to stunning results in textile printing.

Understanding Fabric Compatibility in DTF Printing

Different fabrics react differently to DTF printing techniques, necessitating an understanding of fabric compatibility. Knowledge about which materials work best with DTF technology is essential for achieving optimal adhesion and longevity in prints. Cotton and polyester, for instance, each have unique heat requirements, which means adjustments must be made in terms of heat press settings to suit the specific fabric type being used.

Employing the right approach for each fabric also involves considering factors such as weight and texture, which can influence both print quality and adhesion. Therefore, it’s critical for users to reference manufacturer guidelines and conduct thorough tests on various materials to determine the most effective printing methods—ensuring lasting, vibrant designs that withstand wear and wash.

Mastering Adhesive Application Techniques

A pivotal aspect of successful DTF printing is the application of hot melt adhesive powder. Proper adhesive application ensures that designs adhere securely to garments. When using the DTF Gangsheet Builder, spacing decisions become increasingly important; designs should be arranged with care to allow for an even distribution of adhesive post-printing. This meticulous attention to detail greatly enhances the final product’s quality.

Furthermore, effective management of the adhesive process can make a significant difference in production efficiency. Techniques such as using a consistent amount of powder and applying it evenly across designs contribute to improved adhesion and durability of prints. By mastering these adhesive techniques, users can elevate their DTF printing output, resulting in professional-grade custom apparel that stands out in any market.

Essential Heat Press Techniques for DTF Success

Heat press techniques are critical for ensuring successful transfers in DTF printing. Proper temperature management, typically around 320°F (160°C) for approximately 12 seconds, is essential to guarantee strong adhesion between the design and fabric. These settings may vary depending on the type of material being printed, thus it’s crucial to adjust heat press parameters accordingly to achieve the best results.

In addition to temperature, pressure and timing play significant roles in the success of heat transfers. Users should practice consistent application of pressure to promote uniform adhesion across the design. After pressing, allowing the garment to cool before peeling the transfer is vital to prevent lifting, safeguarding the integrity of the print. Mastery of these heat press techniques ensures outstanding quality and longevity in custom apparel printing.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool used in DTF printing that allows users to arrange multiple designs on a single film sheet efficiently. By optimizing design layouts, it saves material and enhances printing efficiency, making it ideal for creating custom apparel.

What are the best practices for using the DTF Gangsheet Builder?

To maximize your results with the DTF Gangsheet Builder, plan your design layout carefully, use high-quality artwork, adjust printer settings for optimal quality, conduct test prints, and consider fabric compatibility for best adhesion when applying prints.

How can I improve the quality of prints created with the DTF Gangsheet Builder?

Improving print quality with the DTF Gangsheet Builder involves using high-resolution images, adjusting print settings, and mastering the adhesive application. Additionally, regular equipment maintenance helps ensure optimal performance and output.

What types of fabric can I use with the DTF Gangsheet Builder?

The DTF Gangsheet Builder is compatible with most textile types, including cotton and polyester. However, each fabric may require different heat settings and care to ensure optimal adhesion and durability of the prints.

What are some common heat press techniques for DTF printing?

Common heat press techniques for DTF printing include using a temperature of around 320°F (160°C) for about 12 seconds, ensuring even pressure, and allowing garments to cool before peeling transfers to prevent lifting of the print.

Can I use the DTF Gangsheet Builder for large production runs?

Yes, the DTF Gangsheet Builder is particularly advantageous for large production runs, as it enables the efficient arrangement of multiple designs on one sheet, significantly reducing material waste and speeding up the custom apparel printing process.

| Key Points | Details |

|---|---|

| Understanding DTF Printing | DTF printing allows for vibrant, high-resolution designs on various fabrics via a special film. |

| Getting Started with DTF Gangsheet Builder | A tool to arrange multiple designs on a single sheet, optimizing material use and printing efficiency. |

| Plan Your Design Layout | Organize designs considering sizes and spacing to avoid overlap and minimize waste. |

| Use High-Quality Artwork | Ensure designs are in vector format or high-resolution to avoid print quality issues. |

| Adjust Settings for Optimal Results | Experiment with printer settings to achieve the best quality results for different designs. |

| Test Your Designs | Conduct test prints to check transfer quality and color fidelity before full production. |

| Consider Fabric Compatibility | Understand specific heat requirements for different fabrics to ensure proper adhesion. |

| Master the Adhesive Process | Ensure even adhesive application for proper print adherence to fabrics. |

| Proper Heat Press Techniques | Follow right settings for heat and pressure to secure the design to the fabric effectively. |

| Maintain Your Equipment | Keep printers and heat presses clean and in good condition for optimal performance. |

Summary

DTF Gangsheet Builder is a transformative tool for enhancing your approach to textile printing. By leveraging best practices such as planning your design layout meticulously, utilizing high-quality artwork, and mastering variable printing conditions, you ensure the best possible outcomes for your projects. To succeed in utilizing the DTF Gangsheet Builder, familiarize yourself with your materials and techniques to maximize efficiency and quality. As you deepen your understanding of DTF printing, you’ll discover that innovation and creativity can blossom, leading you to produce stunning and durable custom apparel that stand out in the market. Embrace these strategies, and watch your artistry shine with the DTF Gangsheet Builder!