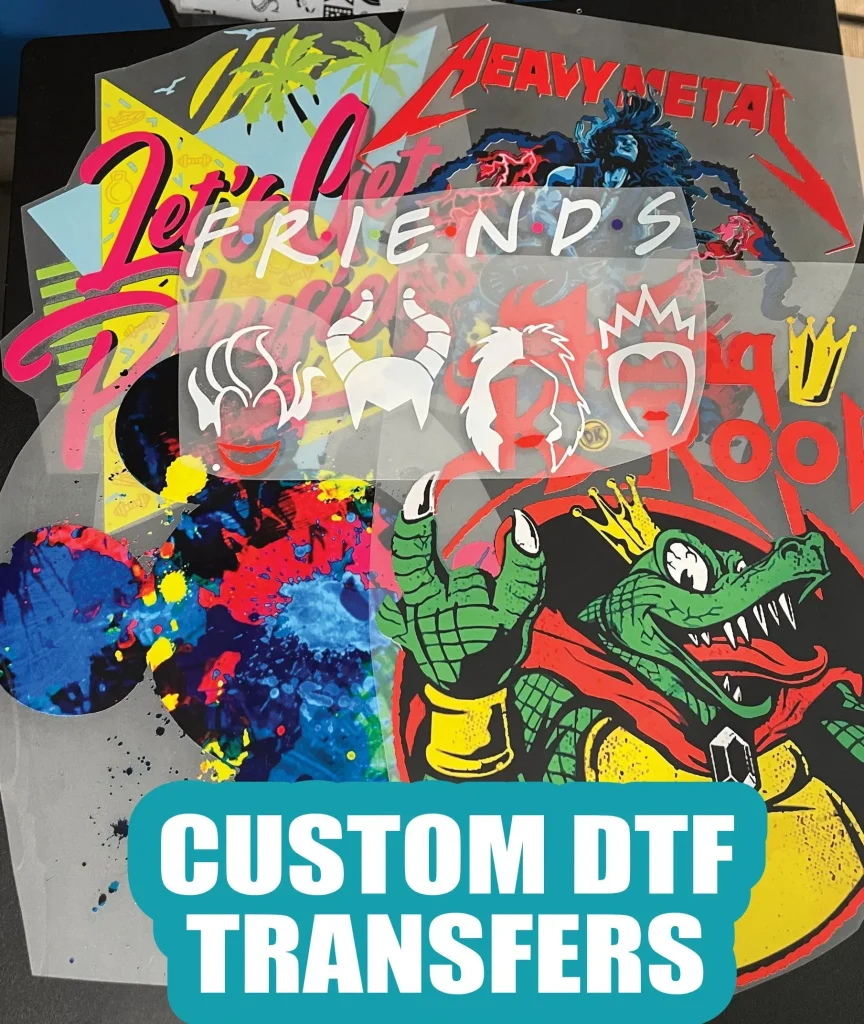

DTF transfers, or Direct to Film transfers, have revolutionized the world of custom apparel printing by offering a seamless and efficient way to apply intricate designs onto garments. This innovative printing technique ensures vibrant colors and high-quality results, making it an essential choice for businesses looking to enhance their garment decoration techniques. With effective DTF printing tips and an understanding of the DTF transfer process, you can elevate your printing capabilities while ensuring customer satisfaction. In this guide, we’ll delve into ten crucial tips that will empower you to master DTF transfers and streamline your production workflow. Embracing this cutting-edge technology could be the key to standing out in today’s competitive market for custom apparel.

Direct to Film transfers, often abbreviated as DTF transfers, utilize advanced printing technology to create stunning designs on clothing. This method, sometimes referred to as DTF printing, allows for precise and durable applications on various fabric types, providing businesses with versatile options for garment decoration. Understanding the essential DTF printing tips can significantly improve the effectiveness of your production and customer appeal. Additionally, exploring the DTF transfer process can unlock new opportunities for customization in your apparel offerings. As the demand for innovative printing solutions grows, harnessing the power of DTF technology is becoming more important than ever for brands seeking to thrive in the custom clothing industry.

Understanding DTF Printing Technology

Direct to Film (DTF) printing technology has revolutionized the way designs are transferred onto textiles. Unlike traditional screen printing, which requires setup and specialized setups, DTF transfers streamline the process by allowing printers to directly apply designs onto a film before transferring them to the garment. This method not only saves time but also allows for high-quality, vibrant prints that are durable and long-lasting. As businesses adopt DTF as a primary method for custom apparel printing, understanding the nuances of this technology can significantly impact their success.

The DTF transfer process involves a few critical steps that ensure the quality of the final product. First, digital designs are printed onto DTF films using special inks. Once the designs are printed, a powdered adhesive is applied to the wet ink, which bonds after heat application. This process is known for its versatility, allowing printers to work with various fabric types, making it a preferred choice for custom apparel printing. Understanding and mastering these techniques can provide a competitive edge in today’s market.

Essential DTF Printing Tips for Success

To excel in DTF printing, employing effective strategies is vital. Start with selecting the right materials, including high-quality films and inks that complement your printer capabilities. Quality materials are imperative as they directly affect the vibrancy and durability of the final prints. Additionally, always conduct thorough research on the DTF transfer process to familiarize yourself with the best practices recommended by industry experts. This knowledge will empower you to tackle common challenges encountered during the printing phase.

Another essential DTF printing tip involves optimizing your designs. Opt for vector graphics to ensure high-quality prints that maintain their resolution under various sizes. Furthermore, use color profiles such as CMYK, as this will enhance color accuracy and consistency in your final prints. In addition, always perform test prints before full production runs, which allows for adjustments and ensures customer satisfaction.

The Importance of Pre-treatment in DTF Transfers

Pre-treatment of fabrics is a crucial stage in the DTF transfer process that often goes overlooked. For optimal adhesion, especially with synthetic materials, using a suitable pre-treatment solution is necessary. This helps create an optimal surface for the ink to bond with the fabric, leading to well-defined prints that endure multiple washes. When commonly overlooked, the lack of pre-treatment can lead to subpar quality and dissatisfied customers, making it an essential step for businesses aiming for excellence.

Understanding the type of fabric you are printing on can further enhance your application of pre-treatment solutions. For instance, cotton fabrics may react differently compared to polyester blends. Knowing these differences allows you to tailor your approach, ensuring that each fabric type receives the appropriate treatment. This will not only improve print quality but also extend the lifespan of the apparel, ensuring that your clients continue to enjoy their custom garments for a longer time.

Optimizing Heat Press Settings for Maximum Output

Heat press settings are another critical factor in achieving great results with DTF transfers. The temperature, pressure, and time duration need to be tailored to match the specific demands of the film and fabric you are working with. Typically, the heat press should operate between 300°F to 320°F for DTF applications, but testing and adjustments may be needed based on garment composition. Understanding these variables can drastically elevate the quality of your prints by ensuring optimal adhesion and finish.

Moreover, experimenting with heat press settings during test prints can help you pinpoint the best combination for different materials. If you notice that prints are peeling or fading after washing, it may be indicative of improper heat application. By keeping detailed records of which settings yield the best results, you can refine your process over time, ultimately leading to improved product quality and greater customer satisfaction.

Post-Printing Care: Best Practices for Longevity

Post-printing care is often neglected but is paramount to the lifespan of DTF transfers. After pressing, prints need to cool down properly to maintain adhesion and quality. Rushing this process can lead to transferred prints that may come off or degrade quickly. As a best practice, always allow your prints adequate cooling time and consider implementing a cooling station to streamline this step in your workflow.

Additionally, educating customers about proper garment care is crucial for preserving the quality of your DTF prints. Provide detailed washing and drying instructions, emphasizing the use of cold water and gentle cycles. Highlighting the importance of turning garments inside out during washing can also prevent damage to the prints. By actively engaging your customers with care information, you not only enhance their product experience but also foster better customer loyalty.

Staying Current in the DTF Industry

Staying updated with the latest advancements in the DTF printing industry is vital for any business aiming to remain competitive. The printing landscape is continuously evolving, and new techniques, materials, and technologies emerge regularly. Engaging with industry forums and attending workshops can provide invaluable insights, enabling printers to adopt innovative practices and solutions that enhance their service offerings.

Additionally, subscribing to industry-related blogs and publications can keep businesses informed about upcoming trends and shifts within the market. By embracing a culture of continuous education, businesses can adapt their strategies to meet changing consumer demands, ensuring long-term growth and sustained customer satisfaction within the realm of DTF transfers.

Frequently Asked Questions

What is the DTF transfer process?

The DTF transfer process involves printing designs directly onto a special DTF film, which is then heat pressed onto garments. This innovative technique allows for high-quality and vibrant prints on a variety of fabrics, making it a popular choice in custom apparel printing.

What are some essential DTF printing tips for beginners?

For beginners in DTF printing, key tips include selecting quality materials, properly setting up your printer, pre-treating fabrics for better adhesion, and optimizing heat press settings. Conducting test prints is also crucial to identify potential issues before full production.

How do I choose the right materials for DTF transfers?

Selecting the right materials for DTF transfers is vital. Use high-quality DTF printing films and inks to ensure vibrant colors and durability. Additionally, choose fabrics that are compatible with DTF printing to maximize adhesion and print quality.

What garment decoration techniques work best with DTF transfers?

DTF transfers are a versatile garment decoration technique that allows for vibrant designs on various fabrics. They work particularly well for custom apparel printing on cotton, polyester, and cotton-poly blends. Experimenting with designs ensures stunning results.

What heat press settings should I use for DTF transfers?

For optimal DTF transfers, familiarize yourself with the correct heat press settings, including the right temperature, pressure, and timing based on the DTF film and fabric type. Starting with the manufacturer’s guidelines and adjusting as needed can enhance print quality.

Why is pre-treatment important in the DTF transfer process?

Pre-treatment is crucial in the DTF transfer process as it enhances adhesion and ensures high-quality prints. Especially on synthetic fabrics, using a pre-treatment solution helps the inks bond effectively, resulting in durable and vibrant designs.

| Tip | Details |

|---|---|

| 1. Choose Quality Materials | Select high-quality DTF films and inks to enhance print vibrancy and durability. |

| 2. Proper Printer Setup | Calibrate your printer settings (temperature, print speeds, resolution) to optimize results. |

| 3. Pre-Treatment of Fabrics | Use pre-treatment solutions on fabrics to improve adhesion and print quality. |

| 4. Heat Press Settings | Know the right temperature, pressure, and timing for different fabrics and films. |

| 5. Design Optimization | Utilize vector graphics and correct color profiles (CMYK) for best results. |

| 6. Test Prints | Conduct test prints to identify issues before mass production saves time and resources. |

| 7. Post-Printing Care | Allow prints to cool properly and follow care instructions to maintain quality. |

| 8. Keep Equipment Clean | Regularly clean printing equipment to avoid quality issues and downtime. |

| 9. Shipping and Handling | Package printed garments carefully to prevent damage during transport. |

| 10. Stay Updated | Stay informed on industry trends and technologies through education and networking. |

Summary

DTF transfers are a revolutionary printing method that can significantly enhance your printing business. By mastering the essential techniques outlined above, you can produce high-quality designs that are vibrant and durable, ensuring customer satisfaction. It is crucial to focus on using quality materials, maintaining equipment, and keeping up with industry trends to stay competitive and efficient in your operations. With dedication and consistent practice, mastering DTF transfers can lead to sustainable growth and success in the custom apparel industry.