DTF transfers, or Direct-to-Film transfers, have revolutionized the custom apparel printing landscape by providing an innovative solution for creating high-quality prints. This cutting-edge DTF printing technique allows for vibrant colors and detailed designs that stand the test of time, making it increasingly popular among designers and businesses alike. With DTF heat transfers, you can achieve exceptional prints on various fabrics, ensuring your creations stand out and make a statement. Whether you’re looking to personalize clothing items or produce promotional merchandise, the versatility of quality prints DTF offers is unmatched. In this guide, we will explore how to effectively use DTF transfers to ensure flawless results every time, dealing with aspects from preparation to application and troubleshooting.

The world of custom printing has seen a significant transformation with the adoption of Direct-to-Film technology, often referred to as DTF printing. This method stands out for its ability to deliver intricate and colorful designs using heat transfer techniques, providing a seamless experience for custom apparel creators. By leveraging DTF heat transfers, users can produce striking, durable prints that cater to a variety of materials, from cotton to polyester blends. The adaptability and ease of use inherent in DTF printing have opened new avenues for brands aiming to thrive in today’s competitive market. In this article, we will delve into the efficient processes involved in using DTF transfers for achieving superior print quality.

Understanding the DTF Printing Technique

Understanding the Direct-to-Film (DTF) printing technique is essential for anyone looking to produce high-quality prints. This method differs significantly from traditional printing processes like screen printing or vinyl transfer, primarily due to its unique capability to produce vibrant, detailed images on a wide range of fabrics. DTF printing involves transferring a design printed on a film directly onto the fabric, ensuring that even the most intricate designs are brought to life with exceptional clarity. By using specialized inks and the appropriate transfer films, DTF ensures that every color pops and remains fade-resistant.

One of the remarkable features of the DTF printing technique is its versatility. It can be applied to various substrates, including cotton, polyester, and cotton-poly blends, thus making it an ideal choice for custom apparel printing. This flexibility allows businesses to cater to diverse customer needs, whether it’s creating unique t-shirts for an event or high-quality labels for products. Moreover, the advancements in DTF printing technology, such as faster printing speeds and better adhesion properties, have made this method increasingly popular among entrepreneurs and hobbyists alike.

Benefits of Using DTF Transfers for Custom Apparel Printing

DTF transfers offer numerous benefits that make them an attractive option for custom apparel printing. Firstly, the color vibrancy and detailing produced through this method are unmatched. Unlike other printing techniques that may dull colors over time or compromise on detail, DTF printing maintains the integrity of the design even after multiple washes. This durability ensures that customers receive products where the prints remain as vibrant as the day they were made, which enhances overall customer satisfaction and brand loyalty.

Additionally, DTF transfers are cost-effective, especially for small-run productions. Because there is no need for screen preparation as in traditional methods, businesses can save on initial setup costs. Furthermore, the ability to print directly onto the film and transfer it onto various fabrics means that designers can easily create and test new products without significant investment. This has made DTF printing a preferred choice for small businesses looking to diversify their offerings without stretching their budgets too thin.

Preparing for Successful DTF Printing

Preparation is key to successful DTF printing, and it begins with selecting the right equipment. Choosing a high-quality DTF printer is vital for ensuring outstanding results. Recent models from trusted manufacturers offer features specifically designed to enhance the DTF printing process, such as optimized ink distribution and precise heat application capabilities. This equipment, coupled with high-quality DTF films and inks, can significantly improve the output of your prints, making the upfront investment worthwhile.

In addition to selecting suitable equipment, design preparation plays a crucial role in achieving the best outcome. It is important to create designs with high resolution and vibrant colors using graphic design software, while also adhering to the CMYK color model. This meticulous approach not only ensures that the colors rendered during printing are accurate but also helps in avoiding common issues like faded prints or color discrepancies. Following these preparation steps will lay a solid foundation for a successful DTF printing experience.

The DTF Printing Process: Step-by-Step Guide

The DTF printing process involves several steps that are critical to achieving flawless prints every time. It begins with printing the design onto a specialized DTF film. It’s vital to adjust the printer settings accurately to ensure that colors and designs are mirrored correctly, as this will affect the final output on the fabric. After printing, an adhesive powder must be applied while the ink is still wet. This crucial step ensures that the design adheres properly during the transfer process.

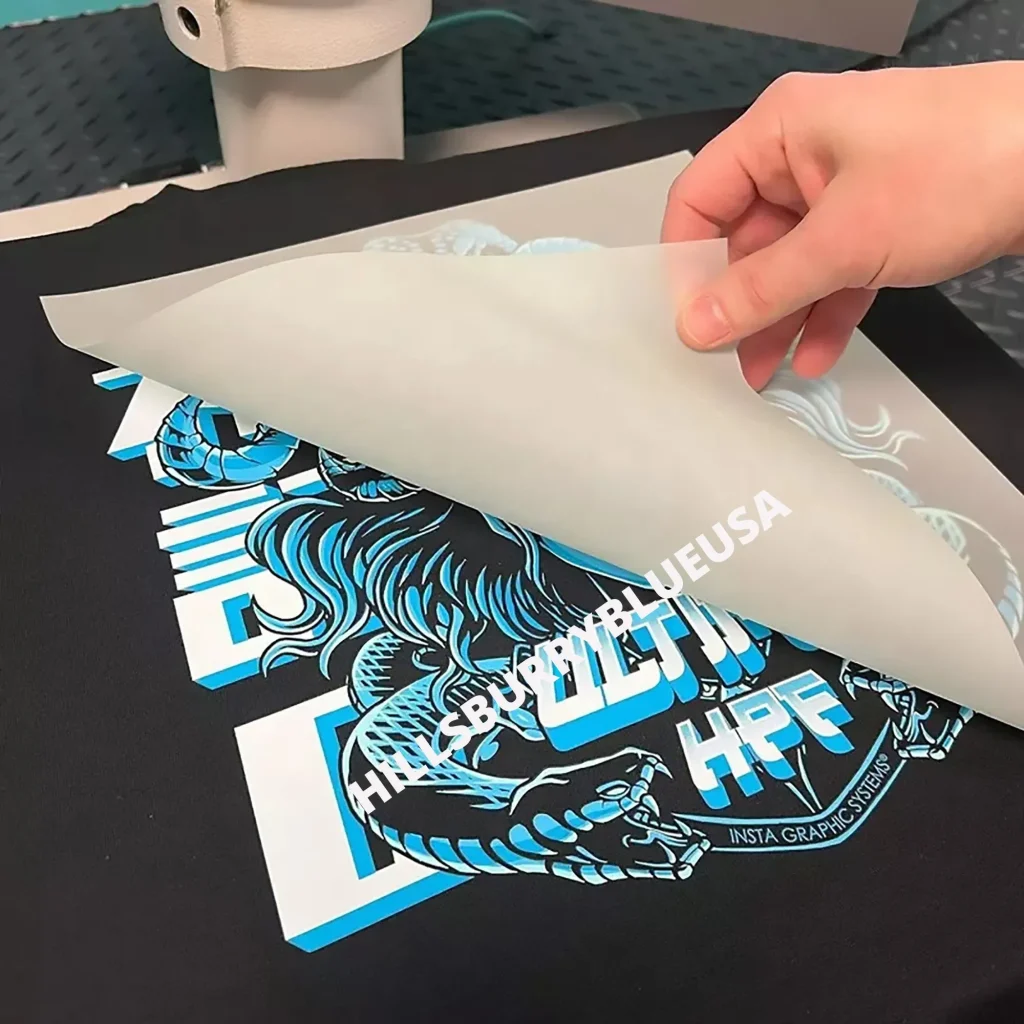

Post-application, using a heat press to bond the printed design to the fabric is essential for longevity. The temperature and pressure settings should be carefully optimized according to the fabric type to prevent issues like peeling edges or cracking designs. After removing the transfer film, a second heat press application can strengthen the bond, ensuring that the design withstands repeated washings. This attention to detail at every stage of the process directly contributes to the quality and durability of the final product.

Troubleshooting Common DTF Printing Issues

Despite the efficiency of DTF printing, you may encounter issues during the process, such as faded prints or peeling edges. To troubleshoot faded prints, it’s crucial to double-check your printer settings, particularly the color profiles and quality settings. Ensuring that you use high-quality inks can also prevent this issue, as lower quality inks may not produce satisfactory results. Additionally, always ensure that your designs are printed in a resolution that matches or exceeds the expected output size.

Peeling edges can occur if the transfer is not applied with enough pressure or heated for the correct amount of time. It’s advisable to run a test on sample fabrics before mass production to determine the optimal settings for heat and pressure. Another common issue is cracking designs, which can often be attributed to improper curing or using a washing method that is too harsh. Adhering to the recommended washing instructions and avoiding the drying machine can prolong the life of DTF prints significantly.

Maintaining the Quality of DTF Prints

Maintaining the quality of DTF prints requires following specific care guidelines. Washing garments in cold water with a mild detergent is essential to preserving the print’s vibrancy and ensuring longevity. High temperatures and harsh chemicals can cause the adhesive to break down faster, leading to premature wear on the design. Additionally, turning printed garments inside out before washing can provide an extra layer of protection, reducing the chances of fading or wear.

Furthermore, avoiding bleach and opting for air drying rather than machine drying can help keep prints looking new for longer periods. It’s crucial for customers to understand these care tips to maximize the longevity of their custom apparel. As a business, providing clear washing and maintenance instructions can minimize return rates due to print degradation, thereby enhancing customer satisfaction and loyalty towards your brand.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a specialized film which is then heat-transferred onto various fabrics. This DTF printing technique allows for vivid colors and intricate designs, making it ideal for custom apparel and promotional items.

What are the advantages of using DTF heat transfers for custom apparel?

Using DTF heat transfers offers several advantages, including exceptional color vibrancy, durability, and the ability to print on a variety of materials. This method ensures long-lasting prints that maintain quality even after multiple washes—perfect for custom apparel printing.

How do I prepare designs for DTF printing to ensure quality prints?

To prepare designs for DTF printing, use graphic design software to create high-resolution images, and ensure the color settings are in CMYK mode. This will help achieve the best quality prints with DTF transfers, reflecting true colors after printing.

What should I consider when choosing a DTF printer?

When selecting a DTF printer, consider factors like print quality, speed, and compatibility with DTF films and inks. Investing in a reliable printer designed for high-quality DTF printing will save you time and help produce excellent results.

What are common issues with DTF transfers and how can they be resolved?

Common issues with DTF transfers include faded prints, peeling edges, and cracking designs. To resolve these, check printer settings for color accuracy, ensure proper adhesive application, and follow recommended heat settings and curing times.

How do I maintain DTF prints to extend their lifespan?

To maintain DTF prints, always wash garments in cold water with mild detergent, avoid high-temperature drying and bleach, and turn clothes inside out before washing. Proper care will help prolong the life of your DTF transfers.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on a film that can be transferred onto various materials using heat and pressure. |

| Advantages of DTF Transfers | 1. Color Vibrancy: Exceptional colors that stand out. 2. Durability: Long-lasting prints. 3. Versatility: Suitable for a variety of materials. 4. Ease of Use: Compact printers offer efficiency. 5. Adaptability: High-quality prints on different fabrics without loss of detail. |

| Preparation Steps | 1. Choose the Right Equipment: Invest in reliable DTF printers. 2. Quality Film and Inks: Use high-quality materials for optimal results. 3. Design Preparation: Ensure high-resolution designs and proper color modeling. |

| Printing Process | 1. Print the Design: Load film, adjust settings, and print. 2. Apply Adhesive Powder: Use immediately after printing for the best results. 3. Heat Transfer: Properly set temperature and pressure on the fabric. 4. Finalizing the Transfer: Run through a second heat press for adherence. |

| Troubleshooting Issues | 1. Faded Prints: Check printer settings for color accuracy. 2. Peeling Edges: Ensure adequate pressure and timing. 3. Cracking Designs: Follow proper curing and washing instructions. |

| Maintenance Tips | – Wash in cold water with mild detergent. – Avoid bleach and high temperatures in drying. – Turn garments inside out before washing. |

Summary

DTF transfers are revolutionizing the custom printing landscape, allowing creators to achieve stunning prints with exceptional vibrancy and durability. By understanding the essentials of using DTF transfers—including the preparation, printing process, and maintenance best practices—you can ensure remarkable results that satisfy customer expectations and enhance brand identity. With advancements in DTF technology now making high-quality printing accessible, businesses and individuals alike can capitalize on this versatile method to produce eye-catching designs that stand the test of time.