DTF transfers have become a game-changer in the realm of custom apparel, offering a powerful method for artists and designers to showcase their creativity. This innovative technique, known as Direct-to-Film printing, allows for the transfer of vibrant and intricate designs onto a multitude of fabric types with remarkable ease. By utilizing advanced heat press techniques, you can achieve stunning results that adhere perfectly to the material, ensuring durability and visual appeal. In this guide, we will uncover the essential methods and tools necessary to master DTF transfers, including the importance of quality adhesive powder for strong adhesion. Get ready to elevate your design quality and transform your textile projects into exceptional works of art!

As we explore the fascinating world of DTF transfers, also referred to as Direct-to-Film printing, you’ll discover its advantages that extend beyond mere aesthetics. This printing method uniquely blends creativity and technology, enabling the seamless application of custom graphics onto diverse textiles, from t-shirts to tote bags. With the right heat press techniques in place, designers can create eye-catching apparel that truly stands out in the market. The use of precise adhesive powders further enhances the longevity of these designs, making them ideal for any custom apparel enthusiast. Join us as we dive deeper into this transformative approach to fabric printing, showcasing how to achieve remarkable results.

Elevating Artistry with DTF Transfers

DTF transfers represent a remarkable advancement in the world of custom apparel, allowing artists to infuse life and vibrancy into their textile designs. Unlike traditional screen printing methods that have limitations concerning color and detail, DTF printing opens up a realm of creative possibilities. Artists can utilize vibrant pigments and intricate designs, ensuring their work stands out in an increasingly competitive market.

With DTF transfers, the ability to print high-resolution detailed graphics introduces a new level of artistry in clothing and fabric design. These transfers can reproduce gradients and subtle color shifts that were difficult, if not impossible, with older methods. This technology not only empowers designers but also enhances the overall experience for those wearing the apparel, making them walking canvases of remarkable art.

Mastering the DTF Process: Step-by-Step Guide

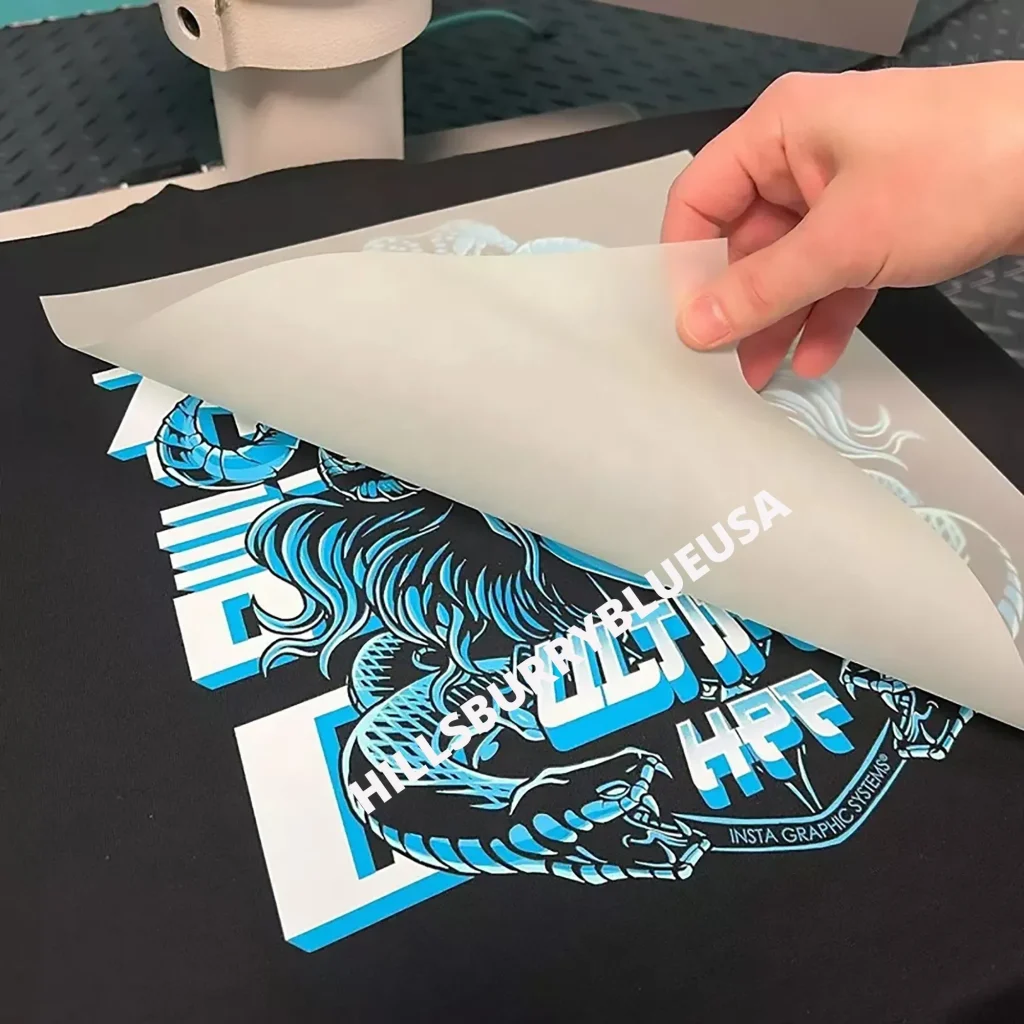

Understanding the DTF printing process is essential for anyone looking to create professional-quality designs. It all begins with the selection of a quality DTF printer equipped to handle eco-solvent inks, as this is crucial for achieving vibrant print colors. Following that, it’s important to apply the adhesive powder correctly; this phase not only enhances the durability of the design but also plays a key role in setting the transfer onto various fabrics.

The final step is heat application using an industrial-grade heat press machine. This equipment is vital since it provides the heat and pressure needed to bond the beautifully printed design to the fabric. Observing proper temperature and timing ensures that the designs adhere well and retain their vibrancy through multiple washes. Mastery of these steps allows individuals to create stunning custom apparel with impressive longevity.

Choosing the Right Equipment for DTF Printing

Investing in quality equipment is pivotal for successful DTF printing. The first major investment should be in a reliable DTF printer, like those offered by Epson or Roland, which are tailored for high-quality transfer production. Additionally, selecting the appropriate heat press is crucial; the ideal model will feature adjustable settings that accommodate various materials and design requirements, ensuring a perfect application every time.

Don’t overlook the importance of transfer films in the process. Opting for the right type – be it matte or glossy – can drastically change the final effect of your designs. Each material reacts differently to the printer and heat application, so experimentation is key. By choosing top-tier equipment and materials, you set yourself up for success in creating beautiful, lasting custom apparel.

Effective Design Techniques for DTF Transfers

When designing for DTF transfers, using high-resolution images is paramount. Images must be clear and detailed to prevent pixelation, which could diminish the finished product’s quality. Employing professional software, such as Adobe Illustrator, allows designers to create layered pieces that can be manipulated for color depth and contrast, further enhancing the final print.

Furthermore, practicing effective layering techniques is essential in DTF printing. Each layer of the design is printed separately, which opens new avenues for complex and vivid designs. However, caution should be exercised to avoid excessive bulk that may lead to peeling after application. Incorporating border designs can also contribute to both the aesthetic appeal and durability of the garment, ensuring that your artwork remains intact.

Caring for DTF Printed Apparel

To prolong the life of DTF printed clothing, proper post-application care is vital. Washing garments inside out in cold water helps maintain the vibrancy of the prints while protecting them from friction and external wear. This practice is crucial, especially since direct contact with abrasive materials can lead to premature fading or peeling of the design.

Additionally, it’s important to avoid bleach when laundering DTF apparel as harsh chemicals can degrade the adhesive used in the transfer process. Choosing to air dry instead of using a high-heat setting in a dryer also preserves the quality of your prints. Following these simple care tips can significantly enhance the longevity and appearance of your DTF-designed apparel.

Current Trends and Innovations in DTF Printing

The DTF printing market is experiencing dynamic growth recently, primarily fueled by the rise of small businesses eager to capitalise on the custom apparel trend. The introduction of innovative techniques and improved equipment is shaping the future of the industry, providing affordable and high-quality options for entrepreneurs. As new technologies emerge, the design quality of DTF transfers has reached remarkable standards, making it conceivable for even novice designers to achieve professional results.

Social media platforms have played a crucial role in popularising DTF printing techniques, where artists and entrepreneurs share insights, tutorials, and marketing strategies. With an increasingly interconnected community, trends evolve quickly, enabling creators to stay ahead of the curve. This accessibility not only democratizes design but also fosters a sense of collaboration within the DTF printing community, allowing everyone to push boundaries and experiment with their craft.

Frequently Asked Questions

What is the DTF transfer process for custom apparel?

The DTF transfer process begins with Direct-to-Film printing, where designs are printed onto special film using eco-solvent or pigment inks. After printing, an adhesive powder is applied and cured, followed by using a heat press to transfer the design onto the fabric, ensuring durability and vibrant colors.

How do I choose the right adhesive powder for DTF transfers?

Selecting high-quality adhesive powder is crucial for successful DTF transfers. Look for adhesive powders specifically formulated for use with Direct-to-Film printing, as these enhance the bond between the print and fabric, resulting in long-lasting designs.

What types of fabrics work best with DTF transfers?

DTF transfers are versatile and work exceptionally well on a variety of fabrics, including cotton, polyester blends, and even some synthetic materials. Experimenting with different fabrics can help you find the best options for your custom apparel projects.

What heat press techniques should I use for DTF printing?

For DTF printing, it’s important to set your heat press to the correct temperature and pressure settings recommended for the specific adhesive powder and fabric being used. Always preheat the fabric and apply even pressure to ensure a successful transfer and vibrant design quality.

Can I wash DTF-printed apparel, and how should I care for it?

Yes, you can wash DTF-printed apparel. To preserve the design quality, wash the garments inside out in cold water and avoid bleach. Ideally, air dry your items instead of using a dryer to prevent damage to the transfer.

What advantages does Direct-to-Film printing offer for custom designs?

Direct-to-Film printing provides numerous advantages for custom designs, including vibrant color reproduction, the ability to transfer intricate details, and compatibility with a variety of fabrics. These features make DTF transfers a highly sought-after method for producing high-quality custom apparel.

| Key Aspect | Details |

|---|---|

| Introduction | DTF printing revolutionizes custom apparel with vibrant, intricate designs. |

| Transfer Process | Involves printing on film, applying adhesive, and using heat to transfer designs. |

| Essential Equipment | Includes a DTF printer (Epson or Roland), heat press, transfer films, and adhesive powders. |

| Design Techniques | Use high-resolution images, design software, layering techniques, and borders for durability. |

| Post-Application Care | Wash inside out in cold water, avoid bleach, and air dry to preserve quality. |

| Market Trends | Rapid growth in DTF market with social media sharing techniques and designs. |

Summary

DTF Transfers are a revolutionary technique in custom apparel and textile artistry, unlocking the potential for stunning designs on fabric. This detailed guide has explored the entire DTF transfer process from printing to application, along with the important equipment necessary for successful results. Whether you are an artist or designer aiming to elevate your creativity or a small business owner looking to delve into custom apparel, understanding DTF transfers can introduce a new level of quality and vibrancy to your work. With ongoing advancements in the field and community sharing of design techniques, you can stay at the forefront of this growing industry. Embrace DTF transfers to make your artistic visions come to life!