DTF transfers are rapidly transforming the fabric printing landscape, merging innovation with practicality in ways that resonate with both businesses and consumers. The Direct-to-Film printing technology, known for its exceptional versatility and efficiency, allows for vibrant, high-quality designs that are easily applied across various fabric types. By utilizing DTF technology, companies can tap into the growing demand for customized printing, meeting the needs of an increasingly personalized market. Unlike traditional printing methods, DTF provides a more streamlined production process, making it a preferred choice for those looking to expand their product offerings without sacrificing quality. As this dynamic printing solution continues to gain traction, it heralds a new era in the art of fabric printing, where creativity and efficiency go hand in hand.

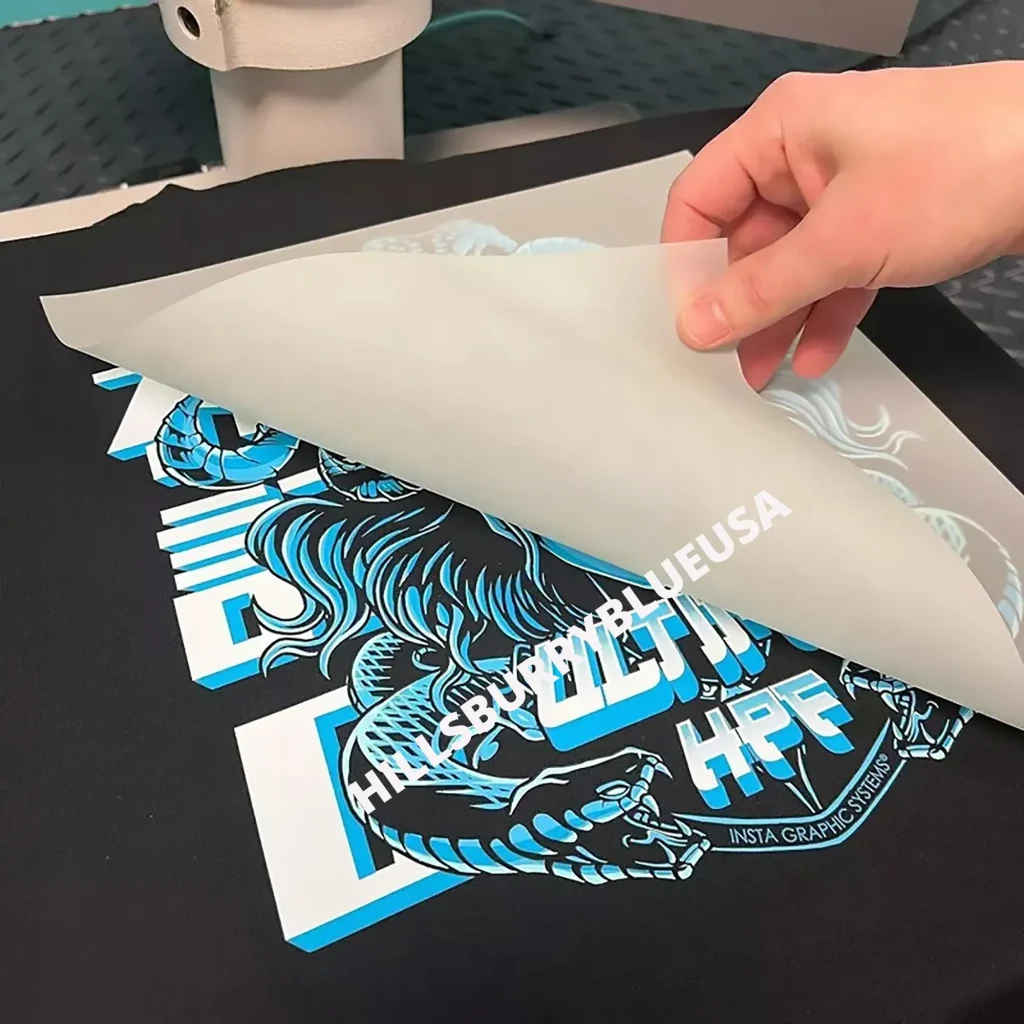

Direct-to-Film printing, often referred to as DTF transfers, represents a revolutionary approach to customized printing in the textile industry. This advanced printing technology allows for the application of detailed designs onto specialized films, which can subsequently be transferred onto fabrics with heat and pressure. Unlike conventional fabric printing techniques, DTF offers remarkable flexibility, making it suitable for a wide range of substrates, including cotton and polyester blends. The growing popularity of this method is largely driven by the increasing consumer demand for personalized apparel and promotional items. As industries embrace the unique advantages of DTF technology, it is poised to redefine the standards of printing efficiency and quality.

Understanding DTF Transfers and Their Advantages

Direct-to-Film (DTF) transfers are changing the landscape of fabric printing by providing a new level of versatility and quality in the printing process. This technology allows for high-resolution images to be printed onto a special film, which is then transferred to a variety of fabric types, including cotton and polyester blends. This ability to work with different fabrics means that businesses can cater to a broader range of customer preferences, making DTF an attractive option in today’s competitive marketplace.

Moreover, DTF printing offers significant advantages over traditional methods like screen printing and direct-to-garment (DTG) printing. The vibrant colors and intricate designs achievable with DTF are unmatched, allowing for eye-catching products that appeal to consumers. Additionally, the durability of the prints ensures that items maintain their quality through multiple washes, which is a crucial factor for companies focusing on customer satisfaction and repeat business.

The Impact of DTF Printing on Cost and Efficiency

One of the standout benefits of DTF printing is its cost-effectiveness, particularly for small and medium-sized enterprises (SMEs). Compared to other printing technologies, DTF printers are generally more affordable, making it easier for startups to enter the fabric printing industry. This affordability allows businesses to experiment with various designs and markets without the risk of high initial investments, ultimately leading to increased competition and innovation.

In addition to lower costs, DTF technology streamlines the production process. The technology enables quicker turnaround times for custom orders, which is particularly beneficial for print shops looking to satisfy specific customer requests. This efficiency not only allows businesses to operate more smoothly but also helps them keep pace with the growing demand for personalized and customized products in the market.

Innovations in DTF Printing Materials and Inks

Advancements in materials and inks used in DTF transfers are transforming the industry, enhancing print quality and longevity. New formulations of printing inks have been developed that improve adhesion to a variety of fabrics, making prints more resilient to wear and washing. As businesses strive for excellence in product offering, these innovations ensure that DTF prints remain vibrant and intact over time.

In response to increasing environmental concerns, many manufacturers are now focusing on eco-friendly inks in the DTF printing process. These sustainable options not only reduce the environmental impact associated with fabric printing but also align with consumer demand for greener products. By adopting such innovations, companies can better position themselves within an industry that is increasingly prioritizing sustainability.

User-Friendly Aspects of DTF Technology

The accessibility of DTF printing technology is one of its key features, making it appealing to a broader audience, including those with limited technical expertise. Recent advancements have simplified the printing process, allowing users to produce high-quality fabrics with minimal training. This user-friendly nature invites more individuals to explore entrepreneurship within the printing industry, fostering creativity and innovation.

As more small business owners adopt DTF technology, the landscape of fabric printing becomes increasingly diverse. New entrants can focus on creative design rather than mastering complex machinery, enabling them to bring unique and customized products to market quickly. This openness not only enhances competition within the industry but also encourages a culture of innovation as fresh ideas and techniques are continuously introduced.

The Growth of the DTF Printing Market

The DTF printing market is witnessing significant growth as awareness of its advantages spreads across various industries. With a projected compound annual growth rate (CAGR) of around 15%, this technology is quickly becoming the go-to solution for businesses looking to enhance their printing capabilities. The versatility of DTF transfers makes it suitable for apparel manufacturers, promotional product companies, and more, catering to a wide array of applications.

As businesses recognize the benefits of DTF technology, they are increasingly adopting it for their operations. The lower entry barriers associated with DTF solutions enable new competitors to emerge, fostering a dynamic market environment. As this trend continues, we can expect further innovations and improvements in printing technology, leading to even greater efficiency and quality in fabric printing.

Customization Trends Driven by DTF Transfers

The rise in consumer demand for personalized products is a major driver behind the DTF printing revolution. As customers seek unique items that reflect their individual styles, DTF technology offers the perfect solution for businesses looking to enter the customization market. With its ability to produce bespoke designs quickly and effectively, DTF printing empowers companies to meet and exceed customer expectations for tailored merchandise.

Furthermore, the rapid prototyping capabilities of DTF technology allow entrepreneurs to test their ideas in real-time and gauge customer interest before committing to large production runs. This agility in the product development process can significantly enhance a business’s ability to adapt to changing trends, solidifying its position in the competitive fabric printing landscape.

Frequently Asked Questions

What is DTF printing and how does it differ from other printing methods?

DTF printing, or Direct-to-Film printing, involves printing designs onto specialized films that can be heat-transferred onto fabrics. Unlike traditional methods such as screen printing, DTF offers greater versatility, enabling high-quality prints on various fabric types, including cotton and polyester, with vibrant colors and durable finishes.

How can DTF Transfers benefit small businesses in the fabric printing industry?

DTF Transfers are cost-effective and user-friendly, making them ideal for small businesses. With lower equipment costs compared to DTG printers, DTF allows startups to offer customized printing services without significant financial investment, while also enabling quicker production runs for personalized merchandise.

What materials and inks are used in DTF printing?

DTF printing utilizes advanced inks and transfer films specially designed for superior adhesion and longevity. Recent innovations in eco-friendly inks are making DTF technology more sustainable, significantly reducing the environmental impact of fabric printing while ensuring high-quality results that endure washes and wear.

What is the market growth outlook for DTF Transfers in the printing industry?

The DTF Transfers market is projected to expand rapidly, with a compound annual growth rate (CAGR) of approximately 15%. As more industries recognize its benefits, including customization capabilities and cost-effectiveness, DTF technology is becoming increasingly popular among businesses of all sizes.

How does DTF printing support customization and personalization trends in fabrics?

DTF printing technology allows for quick prototyping and the ability to produce bespoke designs, catering to the growing demand for personalized merchandise. With DTF Transfers, businesses can easily create unique apparel items that resonate with consumers’ preferences, enhancing their market presence.

What are some advantages of using DTF printing over traditional printing methods?

DTF printing offers several advantages over traditional methods, including versatility on different fabric types, cost savings for small businesses, reduced waste with smaller production runs, faster turnaround times, and the ability to create vibrant, durable designs that meet modern consumer demands.

| Key Points | Details |

|---|---|

| What Are DTF Transfers? | Printing designs onto specialized films that are transferred to fabrics using heat and pressure. |

| Increased Adoption Across Industries | Fashion brands and merchandise companies are utilizing DTF for high-quality, vibrant, and durable prints across various fabric types. |

| Cost-Effectiveness and Efficiency | DTF printers are less expensive than DTG, providing SMEs a way to cut costs and achieve quicker turnaround times. |

| Innovation in Materials and Inks | Advanced inks and eco-friendly formulations enhance print longevity while reducing environmental impact. |

| User-Friendly Technologies | Automation in DTF processes makes the technology accessible even for individuals with limited technical expertise. |

| Market Growth | The global DTF printing market is expected to grow significantly with a forecasted CAGR of around 15%. |

| Customization and Personalization Trends | The rise in demand for personalized products supports DTF’s role in quick prototyping and bespoke design production. |

Summary

DTF transfers are revolutionizing the printing industry by merging innovative technology with heightened customization capabilities and cost-effectiveness. This modern printing method utilizes Direct-to-Film technology to enhance the quality and durability of prints across diverse fabric types, allowing businesses to thrive in a competitive market. As adoption increases, particularly among fashion and promotional sectors, DTF not only meets the rising demand for personalized merchandise but also streamlines production processes. The future of DTF transfers looks promising, with continuous advancements driving market growth and sustainability, making it a pivotal choice for businesses looking to excel in the printing landscape.