DTF transfers, or Direct to Film transfers, are ushering in a new era in the realm of custom t-shirt printing. This innovative technology allows for vibrant, intricate designs to be easily transferred onto fabric, setting a new standard for quality and customization in the printing industry. As businesses and enthusiasts alike embrace DTF printing, they are discovering the immense potential of this method to produce unique apparel with speed and efficiency. Coupled with emerging trends in the printing industry, such as web-to-print platforms, DTF transfers exemplify how technological advancements are reshaping the landscape of t-shirt printing. In this exploration, we will delve into the transformative effects of DTF transfers on how creators bring their designs to life and meet consumer demands.

Direct to Film printing, often referred to as DTF printing, is rapidly altering how custom apparel is produced. By utilizing specialized film to transfer high-quality graphics onto garments, this efficient method ensures that creators can achieve stunning results in a fraction of the time compared to traditional t-shirt printing techniques. The flexibility and versatility that DTF offers make it an attractive option for businesses looking to stand out in a crowded market. As the printing industry continues to evolve, the adoption of DTF technology signals a significant shift towards more innovative and accessible custom t-shirt printing solutions. With the ongoing integration of advanced printing technologies, creators are empowered to explore new design possibilities and cater to diverse consumer needs.

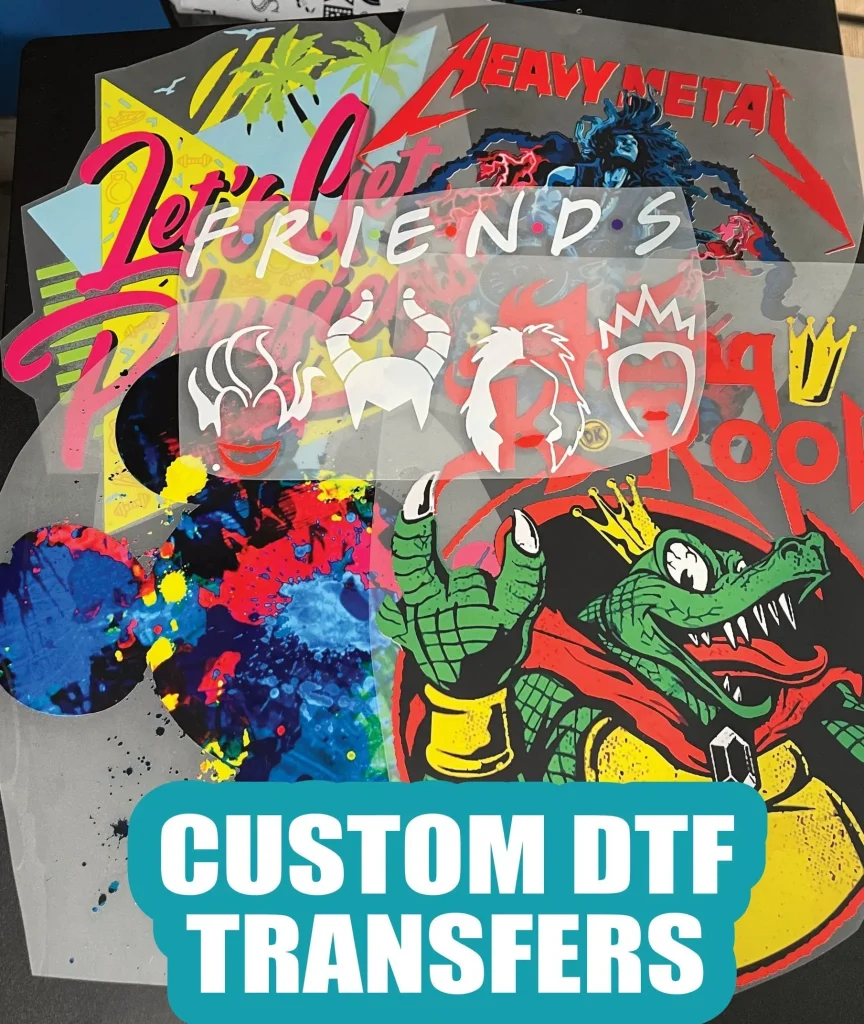

Understanding DTF Printing Technology

Direct to Film (DTF) printing technology is a breakthrough in custom apparel creation that is changing the way designs are established and transferred onto garments. By utilizing a specialized film to print high-quality full-color designs, DTF printing not only enhances the visual appeal of finished products but also increases production efficiency. The process involves directly printing onto a transfer film, which captures every detail of the design before being heat pressed onto the fabric, ensuring vibrant colors and durable prints.

This revolutionary method stands out in the t-shirt printing industry due to its versatility and quality. Unlike traditional printing techniques that may falter on complex designs or multiple colors, DTF printing empowers creators to bring intricate visuals to life with utmost clarity. With the flexibility to print on a variety of materials, DTF technology is redefining the boundaries of custom t-shirt printing.

The Benefits of DTF Transfers

DTF transfers offer a multitude of advantages that appeal to both businesses and individual creators. One key benefit is the ability to produce personalized designs at scale without incurring exorbitant costs, which is especially important in today’s market where customization is highly valued. With rapid production cycles enabled by DTF technology, businesses can respond quickly to consumer demands, keeping them ahead of the curve in the competitive printing industry.

Additionally, the efficiency of DTF transfers minimizes waste and enhances profitability for custom t-shirt printing companies. High-resolution, vibrant colors produced through this method establish a new standard for quality that customers expect and appreciate. As a result, businesses can cultivate a loyal customer base, ultimately leading to increased sales and brand reputation.

Key Trends in T-Shirt Printing

The t-shirt printing industry is currently experiencing significant shifts with the integration of DTF technology. As businesses adapt to modern consumer preferences, trends indicate a growing inclination toward on-demand printing and more personalized experiences. This transition is largely fueled by advancements in digital printing technologies, including DTF, which allow for fast turnaround times without compromising on quality.

Moreover, eco-friendly practices are emerging as pivotal trends in the printing industry. With sustainability becoming a dominant concern, DTF transfers provide a more environmentally responsible option against traditional printing methods that often require extensive resources and produce considerable waste. As this awareness grows, so does the demand for innovative technologies that align with eco-conscious consumer values.

The Role of New Printing Technologies

As the printing industry evolves, emerging technologies like the LOKLiK iPrinter DTF are setting new standards for quality and efficiency. This cutting-edge printer offers superior print resolution and flexibility, enabling users to create a wide range of intricate designs effortlessly. Such advancements not only enhance the capabilities of printing businesses but also elevate the overall quality of custom apparel available in the market.

These innovations provide businesses with an edge, allowing them to meet specific customer demands and trends more adeptly. The introduction of such technology into the DTF market illustrates a commitment to excellence and continuous improvement that is essential for companies striving to maintain relevance in an ever-changing landscape.

Customization Options with DTF Transfers

DTF transfers are synonymous with customization, allowing creators to explore limitless design possibilities without the constraints typical of other printing methods. This level of personalization not only enriches the customer experience but also fosters loyalty, as customers appreciate having unique, tailor-made items that reflect their individual styles. Businesses can cater to various market segments—from fashion enthusiasts to corporate clients—by offering personalized t-shirt designs that resonate with different demographics.

Furthermore, the ability to incorporate unique elements such as names, slogans, and intricate graphics keeps firms competitive in the custom t-shirt printing arena. By harnessing the power of DTF technology, brands can establish a niche that appeals directly to their target audience, fostering stronger connections and promoting healthy growth.

The Future of DTF in Custom T-Shirt Printing

Looking ahead, the future of DTF transfers in the custom t-shirt printing industry appears bright as ongoing developments promise further enhancements. Innovations in printing techniques, adhesive applications, and curing methods indicate that DTF technology will continue to advance, providing even greater efficiency and quality. This progression not only benefits printing companies but also enriches the end-user experience, as they gain access to superior custom products.

As consumer expectations evolve—favoring speed, quality, and personalization—DTF transfers are poised to meet these demands head-on. The combination of technological advancement and market responsiveness will solidify DTF’s position as a fundamental player in the printing industry for years to come, positioning it as a go-to choice for businesses venturing into the world of custom apparel.

Frequently Asked Questions

What are DTF transfers in the context of custom t-shirt printing?

DTF transfers, or Direct to Film transfers, represent a modern printing method that prints designs directly onto a special film before transferring them onto garments like t-shirts. This technique allows for vibrant, full-color designs and offers significant advantages over traditional printing methods, making it a popular choice in the custom t-shirt printing industry.

How does the DTF printing process compare to traditional t-shirt printing methods?

Unlike traditional methods such as screen printing or heat transfer vinyl, DTF printing involves printing designs onto film, applying a powder adhesive, and using heat to transfer the design onto fabric. This method allows for intricate, high-quality designs with shorter production times and does not require the same setup processes, making it more efficient than conventional techniques.

What advantages do DTF transfers offer for businesses in the printing industry?

DTF transfers provide several advantages, including the ability to create unlimited custom designs without incurring high costs, excellent color quality, and faster production times. The versatility of DTF applications on various fabric types allows businesses to meet diverse customer preferences efficiently, keeping them competitive in the printing industry.

Are DTF transfers suitable for all types of fabric?

Yes, DTF transfers are highly versatile and can be applied to a variety of fabric types, including cotton, polyester, and blended materials. This flexibility allows businesses to cater to different apparel lines and customer needs while maintaining high-quality prints.

What are the latest trends in DTF printing that businesses should be aware of?

Recent trends in DTF printing include advancements in web-to-print platforms, such as the introduction of user-friendly services like Snuggle DTF, and innovative printing equipment like the LOKLiK iPrinter DTF. These developments enhance efficiency, improve print quality, and expand customization options for businesses in the custom t-shirt printing market.

How can new creators get started with DTF transfers for t-shirt printing?

New creators can start with DTF transfers by familiarizing themselves with the printing process and investing in a quality DTF printer. They should explore design software to create unique patterns, utilize web-to-print services to simplify order processing, and consider joining online communities for tips and support in mastering this emerging printing technology.

| Key Developments | Details | |

|---|---|---|

| Custom Transfer Printing Experience | A service launched by DesignBundles.net on April 11, 2025, that enhances the DTF printing experience by allowing tailored transfer designs, reducing production times, and improving customer satisfaction. | |

| Web-to-Print Platform | Snuggle launched its DTF platform on April 11, 2025, streamlining access to high-quality DTF services for commercial print trade, enhancing operational efficacy. | |

| New DTF Printer Model | The LOKLiK iPrinter DTF, launched on March 26, 2025, offers exceptional print quality and flexibility, catering to various imprint sizes and customer demands. | |

Summary

DTF Transfers are reshaping the t-shirt printing industry, offering unprecedented customization options and production efficiency. This revolutionary technology enables creators and businesses alike to produce high-quality, intricate designs on a variety of fabrics quickly and cost-effectively. The emergence of new resources, such as the Snuggle DTF platform and innovative printers like the LOKLiK iPrinter DTF, underscore the significant advancements that are defining the future of custom apparel printing. As technology continues to evolve, understanding and utilizing DTF transfers will become essential for anyone looking to succeed in the competitive landscape of custom t-shirt printing.