In the rapidly evolving world of printing, DTF transfers have emerged as a game-changing innovation that is capturing the attention of printers everywhere. Direct-to-Film printing technology blends the convenience of traditional transfer printing with exceptional print quality, enabling vibrant designs on a variety of substrates. As businesses and consumers increasingly prioritize sustainability, DTF transfers stand out for their reduced waste and more eco-friendly approach compared to older methods. Whether you’re a seasoned professional or a curious novice, understanding this advanced printing technology can help elevate your projects to new heights. Join us as we delve into the numerous advantages of DTF transfers and discover how they can revolutionize your printing experience.

Understanding the concept of Direct-to-Film transfers often involves exploring synonymous terms and alternative phrases that highlight their significance in modern printing. This innovative method, frequently referred to as DTF printing, utilizes a specialized technology that prints designs directly onto a flexible film before transferring them to textured surfaces such as textiles. By leveraging transfer printing techniques, printers can achieve remarkable print quality and more sustainable practices. As the demand for versatile and high-quality outputs grows, terms like film printing and sustainable printing become integral to discussions surrounding DTF. Consequently, recognizing these alternative expressions can enhance one’s comprehension of how DTF technology is shaping the future of the printing industry.

Understanding the DTF Printing Process

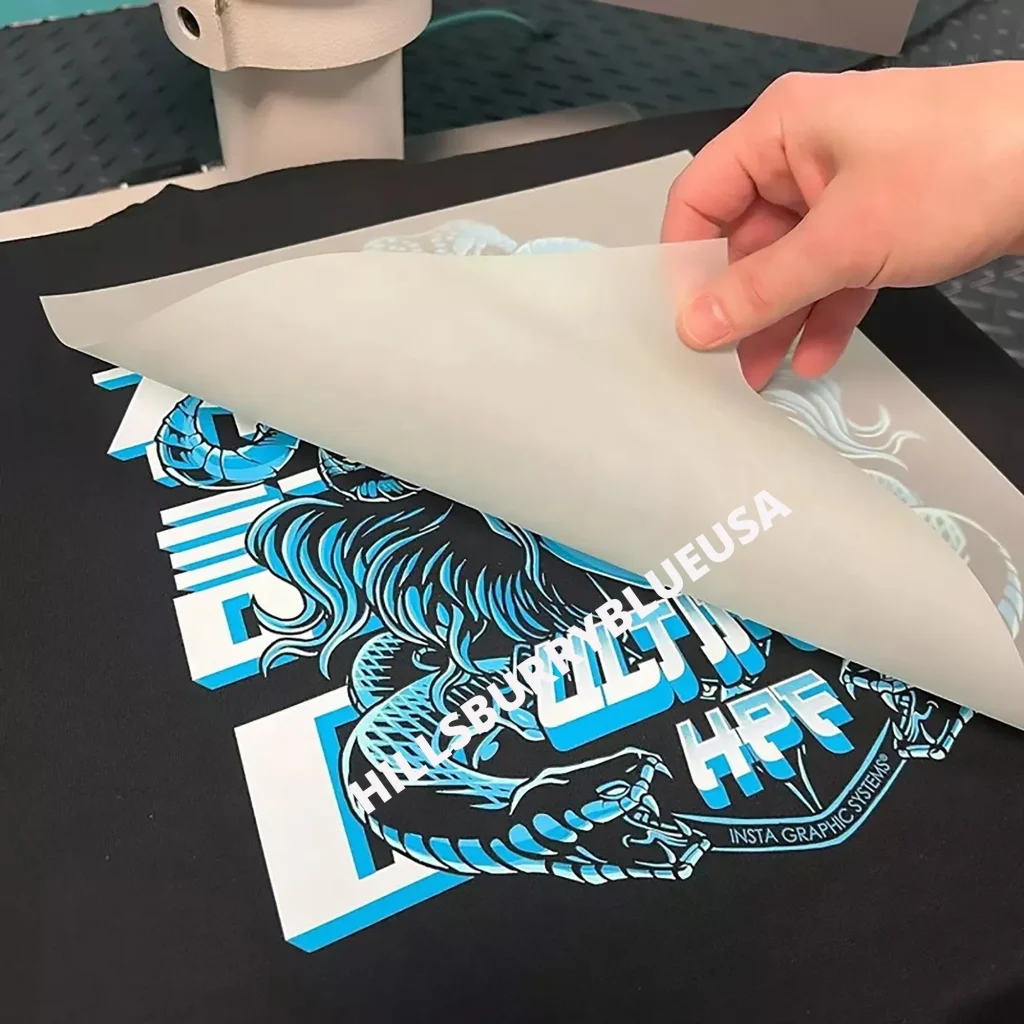

DTF printing revolves around a straightforward and efficient process that combines creativity with technology. The core of the operation involves printing a design onto a specialized film, which is subsequently treated with an adhesive powder. This adhesive helps the design bond securely to the substrate—a crucial step that distinguishes DTF from traditional transfer methods. After applying heat and pressure with a heat press, the result is a crisp, vibrant image that doesn’t fade easily even with extensive wash and wear. Such advancements in printing technology make DTF an appealing choice for modern print shops searching for quality and longevity in their products.

Moreover, understanding the key components of the DTF printing process helps emphasize its efficiency. The use of high-quality films and the precise adjustment of printer settings play pivotal roles in achieving optimal results. Each step, from design creation to final heat pressing, is designed for simplicity, ensuring that both novice and experienced printers can successfully navigate the DTF landscape. As a result, the process ensures not only aesthetically pleasing outcomes but also a quicker turnaround time—an essential factor for meeting market demands.

The Sustainability Aspect of DTF Transfers

In recent years, sustainability has shifted from being an option to a necessity within various industries, and printing is no exception. DTF transfers significantly contribute to this green movement by reducing waste throughout the production process. Unlike traditional screen printing methods, which often involve excess material usage and more complex cleanup, DTF printing minimizes waste through its straightforward transfer approach. By employing efficient printing technology that only uses what’s needed, DTF is helping printers align with global sustainability goals, making it a favorite for eco-conscious businesses and consumers alike.

Additionally, this sustainable edge resonates well with today’s consumers who increasingly prioritize brands with green practices. DTF printing not only addresses environmental concerns but also offers high-quality results that do not compromise on aesthetic appeal. This dual focus on quality and sustainability allows businesses utilizing DTF transfers to enhance their reputation and customer trust while playing their part in protecting the planet.

Unmatched Print Quality with DTF Technology

One of the most acclaimed features of DTF transfers is their capability to produce print quality that rivals, and often exceeds, traditional methods like screen printing and sublimation. DTF technology incorporates advanced ink formulations and precise printing techniques that allow for vibrant colors and intricate details, ensuring every design comes to life on fabric. As brands and designers push for more complex visuals, DTF proves to be an invaluable tool, capable of producing high-resolution images without the need for separating designs into different color screens.

With the rise of large-format printers, as evidenced by companies like EazyDTF expanding their offerings, the potential for stunning print quality continues to grow. This ensures printers can meet the demands of varied markets, producing everything from simple logos to elaborate artwork on a myriad of textiles. The result is a significant advancement in capability, making DTF an attractive choice for businesses looking to differentiate themselves in a competitive landscape.

Versatility of DTF Transfers in Textiles

The versatility of DTF transfers is one of the most distinctive advantages of this printing technology. Unlike sublimation printing, which is primarily effective on 100% polyester materials, DTF transfers can be applied to a wide range of substrates, including cotton, blends, and other fabrics. This flexibility allows printers to cater to diverse markets, from apparel manufacturers needing vibrant designs on different textiles to hobbyists looking to experiment with various materials.

As the demand for customized clothing rises, the ability to utilize DTF transfers across multiple fabric types signifies a major leap in printing functionality. This not only opens avenues for creativity but also enables businesses to expand their product lines without the need for extensive equipment changes or specialized inks. The multi-fabric application of DTF technology empowers printers to respond dynamically to consumer requests for quality and variety in their print offerings.

Comparative Analysis: DTF vs. Traditional Printing Methods

When evaluating printing options, it is essential to conduct a comparative analysis to make informed decisions. DTF transfers stand out compared to traditional methods like screen printing and sublimation due to their versatility and efficiency. While screen printing can be cost-effective for high-volume orders, it often accommodates limited color details and requires complex setup for multi-colored designs. Conversely, DTF offers a streamlined process for small to medium runs, allowing for detailed graphics with less hassle and greater flexibility.

Furthermore, when juxtaposed with sublimation, the DTF method allows for a wider pool of materials to print on, making it appealing for those looking to diversify their product offerings. While sublimation is excellent for vibrant prints on polyester, DTF expands beyond that limitation, ensuring that printers can meet client needs for various habitat and clothing options. This comparative understanding aids businesses in making choices that align not only with their operational needs but also with their clientele’s priorities.

Future Trends in DTF Printing Technology

The future of DTF printing technology appears overwhelmingly promising, with advancements continuously shaping its evolution. As companies ramp up their investments in new printing technologies and materials, we can anticipate enhanced print quality and production speeds that would redefine industry standards. Innovations such as improved ink formulations and automated processes aim to streamline the DTF workflow, making it even more accessible for printers at all levels.

In addition, with increasing focus on customer satisfaction and the importance of quick turnaround times, DTF technology is expected to integrate seamlessly with processes such as same-day shipping and efficient order fulfillment. This shift not only enhances service delivery but also plays a significant role in the competitive landscape, where the ability to adapt quickly can be a game-changer. As the print industry continues to evolve, embracing the advancements of DTF will undoubtedly empower printers and open new doors to creativity and consumer engagement.

Frequently Asked Questions

What are DTF transfers and how do they work in printing technology?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film that is later heat-pressed onto various substrates like textiles. This innovative printing technology allows for vibrant colors and intricate details, making it ideal for high-quality prints across multiple materials.

How do DTF transfers contribute to sustainable printing practices?

DTF transfers prioritize sustainability by significantly reducing waste during the printing process compared to traditional methods like screen printing. This eco-friendly approach aligns with modern sustainability goals, appealing to consumers who demand greener practices in the garment printing industry.

What advantages do DTF transfers offer over other printing methods?

Compared to sublimation and screen printing, DTF transfers provide more versatility as they can be used on both natural and synthetic fabrics. They also excel at producing intricate designs with rich color detail, making them a better choice for small to medium print runs when complexity is needed.

Are DTF transfers easy to use for beginners in the printing industry?

Yes, DTF transfers are user-friendly and suitable for printers of all skill levels. The process involves straightforward steps: printing the design on film, applying adhesive powder, and heat pressing it onto the desired substrate, making it accessible for hobbyists and small business owners alike.

What should I consider for optimal print quality when using DTF transfers?

For the best print quality with DTF transfers, use high-quality films and adjust your printer settings according to the substrate type. Additionally, conducting sample tests before large runs can help ensure your designs achieve the desired results consistently.

What is the future outlook for DTF printing technology?

The future of DTF printing looks promising, with ongoing advancements in technology expected to enhance print quality and production efficiency. With companies increasing their investment in DTF, the method is set to become even more popular among printers seeking sustainable and versatile printing options.

| Advantage | Description |

|---|---|

| Sustainability and Eco-Friendliness | Reduces waste significantly in the printing process, aligning with modern sustainability goals. |

| High-Quality Prints | Produces vibrant colors and intricate designs, surpassing many traditional methods. |

| Ease of Use | Simple 3-step process makes it accessible for all skill levels, enhancing speed and usability. |

| Versatility | Compatible with a wide range of materials, including cotton and polyester, unlike methods like sublimation. |

Summary

DTF transfers have revolutionized the printing industry, providing a modern solution that combines sustainability, high-quality output, and user-friendliness. As consumers and businesses increasingly prioritize eco-friendly practices, DTF transfers stand out by minimizing waste without sacrificing quality. Their ability to produce vibrant prints on various materials makes DTF an exceptionally versatile choice for printers. As the technology continues to evolve, we anticipate even further advancements in print quality and efficiency, solidifying DTF transfers as a preferred option for both small businesses and hobbyists alike. Embracing DTF transfers not only enhances your printing capabilities but also aligns with a greener future in the printing landscape.