DTF transfers, or Direct-to-Film transfers, are revolutionizing the garment printing industry by combining exceptional quality with remarkable versatility. This innovative printing technology provides businesses with the ability to create vibrant and durable designs on a wide range of materials, including cotton, polyester, and various blends. In recent years, brands like Snuggle and EazyDTF have expanded their offerings to package DTF printing as a fast and efficient alternative to traditional methods, such as sublimation printing and screen printing. As a result, DTF transfers have become a favorite among creators, entrepreneurs, and established businesses alike, looking to produce high-quality printed apparel that stands out. With their unique benefits, DTF transfers are poised to dominate the future of garment personalization.

The emergence of Direct-to-Film printing has ushered in a new era for the textile industry, introducing a method that seamlessly adapts to diverse fabric applications. This innovative approach to garment decoration, which can also be referred to as DTF printing, allows for quicker turnarounds and superior durability compared to older techniques like sublimation printing. Companies are now harnessing this advanced technology to deliver eye-catching prints that are both stylish and resilient, appealing to a broad customer base. By leveraging the advantages of Direct-to-Film transfers, businesses can meet the growing demand for high-quality, personalized items while maintaining efficiency in production. This shift in printing technology promises to enhance creativity and foster sustainability in the garment market.

Understanding DTF Transfers and Their Applications

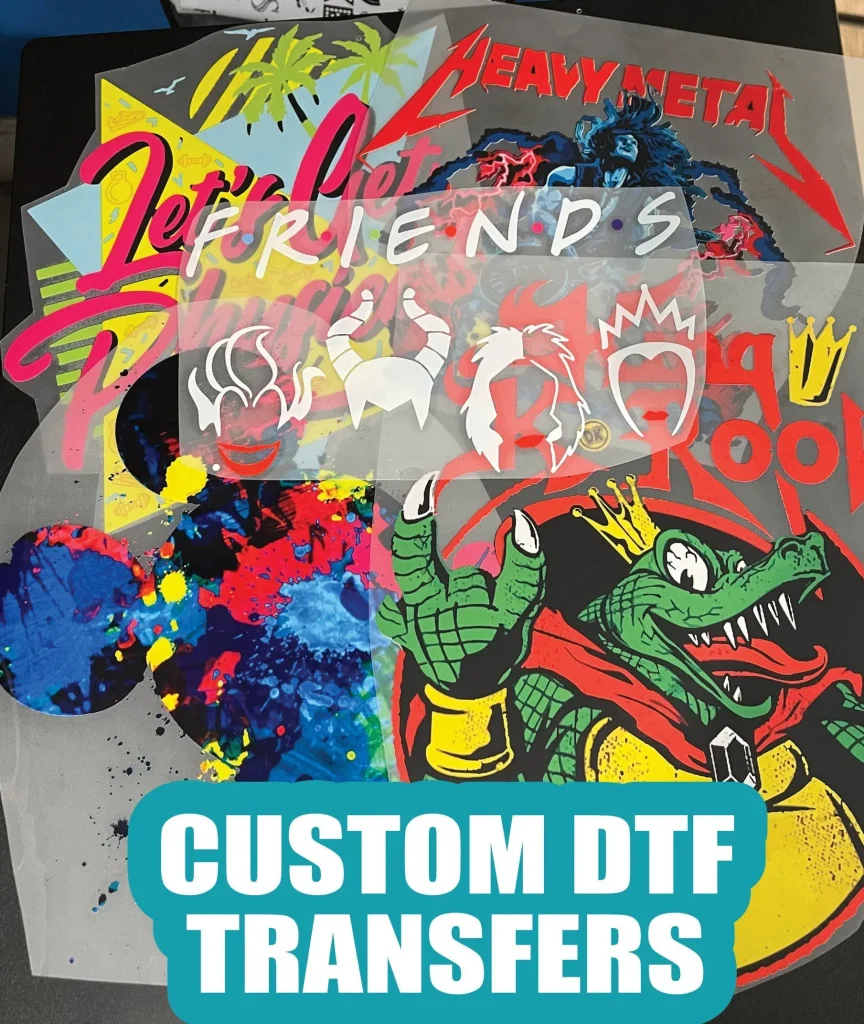

Direct-to-Film (DTF) transfers are a revolutionary method of printing that involves applying a design onto a film and then transferring it to various garment materials using heat. This technology allows for unmatched versatility across different fabric types, making it ideal for custom apparel, promotional items, and fashion lines. The ability to print vibrant designs on both cotton and polyester fabrics opens up new possibilities for designers and businesses alike, paving the way for creative expression in garment printing.

Moreover, DTF transfers have gained traction not just within the garment industry but also in the crafting community. Their adaptability makes them suitable for a range of projects, from T-shirts and hoodies to bags and home textiles. This breadth of application means that crafters can explore new design options without being limited to a single type of fabric, creating a dynamic environment for innovation. As the popularity of DTF continues to rise, understanding its applications will be essential for anyone looking to leverage this technology.

Key Advantages of Direct-to-Film Printing

One of the standout advantages of DTF transfers is their impressive flexibility across various materials. Unlike sublimation printing, which can only produce exceptional prints on polyester, DTF technology excels in delivering brilliant, durable images on cotton and even blends of fabrics. This characteristic makes DTF the go-to choice for businesses that cater to diverse customer needs and seek to expand their product offerings.

Additionally, the high-speed production capabilities associated with DTF transfers are another major benefit. Leading companies like Snuggle have demonstrated that daily output can reach up to 10,000 A4 transfers, allowing businesses to fulfill large orders swiftly. This efficiency not only meets customer demands but also enhances overall satisfaction, as clients receive their products faster without compromising quality.

Comparing DTF Transfers with Other Printing Technologies

When evaluating printing methods, DTF transfers stand out against traditional screen printing and sublimation. While screen printing involves cumbersome setups and is often limited by color complexity, DTF simplifies the printing process, enabling intricate designs to be transferred seamlessly. This ease of use is a significant advantage for both commercial enterprises and hobbyists.

Moreover, compared to sublimation printing, DTF offers greater versatility. Sublimation is limited to synthetic fabrics, while DTF allows for excellent results on cotton and other materials. For businesses that previously encountered barriers using sublimation, DTF presents an opportunity to cater to a broader market, reaching customers who seek printed products on a variety of fabric types.

The Impact of Technology on DTF Printing

Technological advancements have played a critical role in enhancing the capabilities of DTF transfers. Companies like EazyDTF are investing in advanced equipment, significantly boosting production capacities and improving print quality. These advancements ensure that businesses can meet rising consumer demands for personalized and high-quality printed garments without compromising on turnaround times.

Furthermore, the integration of web-to-print solutions is revolutionizing how businesses approach order fulfillment. With platforms allowing for easy design uploads and payment processing, companies can streamline their operations and reduce the time spent on administrative tasks. This technology empowers smaller businesses to compete effectively, harnessing the potential of DTF transfers to enter a market that traditionally favors larger entities.

Exploring the Sustainability of DTF Transfers

Sustainability is a growing concern in the printing industry, and DTF transfers offer a more eco-friendly alternative to traditional methods. The removability of DTF prints means that garment makers can easily update or recycle designs without damaging the underlying fabric. This capability promotes responsible practices and reduces waste, which is increasingly important to consumers.

Additionally, the strong adhesion and durability of DTF prints ensure that garments stand up to wear and washing, prolonging their lifespan. Businesses that prioritize longevity in their products are likely to gain a competitive edge, as customers increasingly seek sustainable and high-quality goods. By opting for DTF technology, companies not only contribute to a more sustainable industry but also meet the evolving expectations of their clientele.

Final Thoughts on the Future of DTF Printing in Garment Production

As we explore the potential of DTF transfers within the broader realm of garment production, it becomes clear that these innovations are setting new standards in quality and efficiency. The flexibility of DTF technology allows designers and businesses to produce customized pieces that resonate with their target audiences, opening channels for creativity and personalization.

The ongoing advancements in DTF technology, combined with user-friendly solutions, promise to reshape the landscape of garment printing. Companies that embrace DTF will not only enhance their service offerings but also position themselves for success in a rapidly changing marketplace. It’s an exciting time for the printing industry, and DTF transfers are undoubtedly at the forefront of this evolution.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film that can be heat-pressed onto various garment materials. This method allows for vibrant and durable prints on fabrics like cotton, polyester, and blends, making DTF printing a versatile choice for garment personalization.

How do DTF transfers differ from sublimation printing?

Unlike sublimation printing, which primarily works on polyester materials, DTF transfers are compatible with a wider variety of fabrics. This capability allows businesses to create high-quality prints on cotton and blended materials, addressing a broader market and offering more options for garment printing.

What are the benefits of using DTF printing technology?

The benefits of DTF printing technology include flexibility across materials, high-speed production, and superior durability of prints. DTF transfers maintain vibrant colors and integrity after multiple washes, making them ideal for both commercial applications and personal crafting.

Can DTF transfers be removed easily compared to other printing techniques?

Yes, DTF transfers can be removed more easily than methods like screen printing. This ease of removability allows garment makers to recycle and update designs with minimal waste, promoting sustainability in the crafting industry.

What advancements have been made in DTF transfer technology?

Recent advancements in DTF transfer technology include improved printer quality and increased production capacity. Companies like EazyDTF have invested in large-format DTF printers to enhance their output volume and service capabilities, catering to the growing demand for fast and flexible printing solutions.

How do web-to-print solutions impact the use of DTF transfers?

Web-to-print solutions simplify the ordering process for businesses looking to utilize DTF transfers. By enabling resellers to submit designs and process orders online, these solutions eliminate complexity, allowing smaller businesses to compete effectively in the garment printing market.

| Key Points | Details |

|---|---|

| Introduction | DTF transfers are revolutionizing the printing industry by providing versatile and efficient printing solutions. |

| What are DTF Transfers? | Involves printing designs onto special films that are then applied to fabrics using heat and pressure. They allow for a broader range of material compatibility compared to traditional methods. |

| Key Advantages of DTF Transfers | 1. **Flexibility Across Materials**: Suitable for cotton, blends, and polyester. 2. **High-Speed Production**: Capable of producing large volumes quickly. 3. **Durability**: Strong adhesion and vibrant color retention after washing. |

| Technological Advancements | Improvements in equipment and production capacity enhance efficiency and service offerings. |

| Web-to-Print Solutions | Simplifies the ordering process for businesses, allowing easy design submissions and payments online. |

| Comparing DTF and Sublimation | DTF proves more effective on non-polyester materials, enabling broader market reach for businesses. |

| Removability and Practical Uses | DTF transfers can be removed easily, promoting sustainability by allowing updates to designs without waste. |

Summary

DTF transfers are rapidly becoming an essential tool in the world of garment printing. By offering unmatched versatility and efficiency, DTF technology caters to a wide range of materials, making it a go-to option for both personal crafters and commercial enterprises. With advancements in equipment, increased production speeds, and innovative web-to-print solutions, businesses are poised to thrive in a competitive market. The ability to create durable and high-quality prints that adhere well to various fabrics further solidifies DTF transfers as a pivotal development in the printing industry. As the trend continues to grow, exploring DTF transfers may lead to new opportunities for creativity and success in garment production.