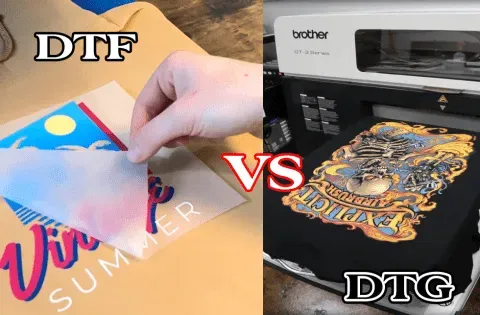

In the realm of custom garment decoration, the debate between DTF vs. DTG is becoming increasingly pertinent for businesses aiming to stand out. DTF (Direct-to-Film) and DTG (Direct-to-Garment) represent two innovative printing methods that cater to different production needs and styles. As we delve into the nuances of these two techniques, we’ll explore their unique features, recent advancements, and their implications for your printing solutions. With DTF printing offering exceptional material compatibility and DTG printing renowned for its vibrant detail, understanding the nuances between these two methods will empower business owners to make informed decisions. Join us as we examine this printing methods comparison to help you find your perfect match in garment decoration innovations.

Exploring the landscape of fabric printing technologies reveals a significant choice for designers and businesses: the DTF technique against the DTG approach. Known as Direct-to-Film and Direct-to-Garment respectively, these methods embody innovative strategies in the world of textile artistry. Each technique offers distinct advantages, whether through the flexibility of garment printing solutions or the richness of detail achievable with their intricate designs. This article will unravel the comprehensive aspects of DTF and DTG, allowing readers to understand which method may align best with their creative visions and operational requirements. Whether you seek cutting-edge efficiency or unparalleled design quality, the choice between these printing technologies will shape the future of your custom apparel endeavors.

Understanding DTF vs. DTG Printing

DTF (Direct-to-Film) and DTG (Direct-to-Garment) printing represent two distinct approaches in the custom printing industry, each tailored to meet specific needs and preferences. DTF printing involves printing designs onto a film, which is then heat transferred onto the fabric. This method has gained traction due to its compatibility with various fabric types, enabling businesses to cater to a broader audience. On the other hand, DTG printing directly applies ink to garments, utilizing specialized inks that bond with the fabric fibers, resulting in visually stunning and detailed prints.

The choice between DTF and DTG can significantly affect the final product quality and overall customer satisfaction. DTF printing excels in its adaptability across different materials, from cotton to synthetics, making it an excellent option for companies wanting to broaden their product lines. Meanwhile, DTG offers superior detail and color vibrancy, which is particularly appealing for intricate designs or artwork with complex color schemes. As such, understanding the nuances of both printing methods can help businesses align their capabilities with market demands.

Frequently Asked Questions

What are the main differences between DTF printing and DTG printing?

The primary differences between DTF (Direct-to-Film) printing and DTG (Direct-to-Garment) printing lie in print quality, material compatibility, speed, and costs. DTG is known for its vibrant colors and detail, making it perfect for intricate designs on cotton fabrics. In contrast, DTF offers broader material compatibility, allowing printing on various fabrics like polyester, and generally delivers faster production times, especially suitable for on-demand orders.

Is DTF printing better than DTG printing for high-volume jobs?

For high-volume jobs, DTF printing often proves to be more efficient than DTG printing. DTF allows for quicker production runs, making it ideal for businesses that require rapid turnarounds. Additionally, DTF’s material versatility enables printing on a wider range of fabrics, which can be beneficial for producing diverse product lines efficiently.

Can I use DTF printing on fabrics other than cotton?

Yes, DTF printing is highly versatile and can be used on a range of fabrics beyond cotton, including polyester and blended materials. This makes DTF a popular choice for businesses looking to expand their product offerings with various fabric options compared to DTG, which is primarily designed for 100% cotton.

What advancements have been made in DTF printing technology recently?

Recent advancements in DTF printing technology include the launch of new platforms, like those introduced by Snuggle, which focus on increasing print speed and customization potential. These innovations allow businesses to adapt to growing customer demands for personalized apparel while enhancing the overall efficiency of the printing process.

How do the costs compare between DTF and DTG printing methods?

The initial setup costs for DTG printing can be relatively high, while DTF printers typically have lower upfront costs. However, long-term costs can vary based on ink, film materials, and maintenance requirements. Businesses should consider these budget implications when choosing between DTF and DTG for their custom printing solutions.

Which printing method, DTF or DTG, offers better print quality?

DTG printing is renowned for its exceptional print quality, producing vivid details and vibrant colors that excel in intricate designs. Although DTF printing has seen improvements in output quality, it may still not match the color depth of DTG. For businesses prioritizing print quality for complex graphics, DTG might be the preferable option.

| Feature | DTF (Direct-to-Film) | DTG (Direct-to-Garment) |

|---|---|---|

| Print Quality | Improved recent innovations; practical for various applications. | Exceptional quality; excels in vibrant, intricate designs. |

| Material Compatibility | Compatible with a wider range including polyester and blends. | Primarily for 100% cotton fabrics; limited versatility. |

| Production Speed | Typically faster, ideal for on-demand printing. | Slower, less economical for bulk orders but good for small quantities. |

| Cost Considerations | Lower upfront costs; varying printing costs based on films. | High initial setup costs; long-term costs depend on maintenance. |

Summary

DTF vs. DTG, two prominent printing methods, present various advantages and considerations for businesses in garment printing. As technology evolves, understanding the unique features of DTF and DTG is crucial for effective decision-making. DTF, with its fast production speed and compatibility with diverse materials, offers flexibility, while DTG shines in print quality, particularly for detailed designs. Businesses should evaluate their specific needs, including customer preferences and budget concerns, to choose the optimal printing solution. With these insights, firms can navigate the dynamic landscape of custom apparel printing effectively.